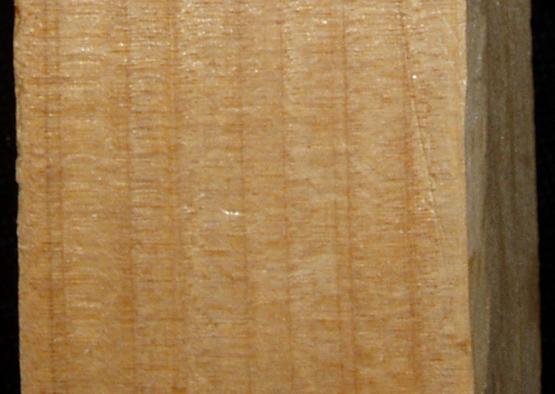

Macrocarpa has yellow-brown heartwood colour, darker in old trees, sapwood 40-50mm, is paler coloured. Air-dry density 475-485 kgm-3, wood is soft with a fragrant, spicy odour.

Monterey cypress (USA), golden cypress (AUST), cypress macrocarpa

Cupressus macrocarpa

Sapwood colour: pale yellow-brown and little different from the yellow-brown heartwood although wood from old trees tends to be darker.

Grain and texture: grain generally straight but can deviate considerably from stem fluting or around knots from large branches of trees grown in open grown shelter belts or plantations. The texture is fine and even with visible growth rings. Tissue gives the wood a lustrous appearance similar to that of hoop or kauri. The heartwood exhibits a fragrant spicy odour or ‘pencils’ similar to that of western red cedar.

The species is originally from the United States of America; in Australia it was commonly used for windbreaks on Victorian farms, where it was planted around 70 to 100 years ago. Now it is increasingly available commercially. Several small sawmilling operations in Victoria are processing the farm-sourced timber. The tree was also introduced to New Zealand in the 1860’s, tropical Africa and Madagascar and was planted mainly in shelter belts but occasionally in plantations in New Zealand.

The wood is a lightweight softwood (475-485 kg/m3 at 12% MC) and is a moderately stiff, strong timber similar to NZ grown Douglas Fir, it can be difficult to kiln dry, usually exhibiting collapse and sometimes internal checking.

The wood saws and works easily owing to its fine texture. It holds nails well and the gluing and painting properties are good. It is one of the most naturally durable exotic softwoods grown in New Zealand, and is resistant to insect and borer attack in sawn form. The heartwood is rated moderately durable (Class 3) in ground which means that a 50x50 stake will last 10-15 years. Larger sections will last longer. Above ground it is regarded as equivalent to H3 pine. It is reportedly, naturally, termite-resistant (http://www.jedwoodtimber.com.au/cypress.html) although no published test data is available.

Shrinkage

| Very Low | Low | Medium | High | Very High | |

|---|---|---|---|---|---|

|

|

||||

Tangential : |

3.30%

|

||||

Radial : |

1.60%

|

||||

Unit Movement Tangential: |

0.25%

|

||||

Unit Movement Radial: |

0.12%

|

Strength Group

Very High |

High |

Reasonably High |

Medium High |

Medium |

Reasonably Low |

Low |

Very Low |

||

Unseasoned: |

S1 |

S2 |

S3 |

S4 |

S5 |

S6 |

S7 |

S8 |

|

|---|---|---|---|---|---|---|---|---|---|

Seasoned: |

SD1 |

SD2 |

SD3 |

SD4 |

SD5 |

SD6 |

SD7 |

SD8 |

|

Stress Grade

| Structural No. 1 |

Structural No. 2 |

Structural No. 3 |

Structural No. 4 |

Structural No. 5 |

|

Unseasoned: |

|

|

|

|

|

Seasoned: |

|

|

|

|

|

Density per Standard

Seasoned: |

480kg/m3

|

|---|---|

Unseasoned: |

820kg/m3

|

Joint Group

Very High |

High |

Reasonably High |

Medium |

Low |

Very Low |

|

Unseasoned: |

J1 |

J2 |

J3 |

J4 |

J5 |

J6 |

|---|---|---|---|---|---|---|

|

||||||

Seasoned: |

JD1 |

JD2 |

JD3 |

JD4 |

JD5 |

JD6 |

Colour

| White, yellow, pale straw to light brown | Pink to pink brown | Light to dark red | Brown, chocolate, mottled or streaky | |

|

||||

Mechanical Properties

Modulus of Rupture - Unseasoned: |

53

|

|---|---|

Modulus of Rupture - Seasoned: |

74.3

|

Modulus of Elasticity - Unseasoned: |

7.1

|

Modulus of Elasticity - Seasoned: |

7.9

|

Maximum Crushing Strength - Unseasoned:  |

23

|

Maximum Crushing Strength - Seasoned: |

40.3

|

Impact - Unseasoned: |

|

Impact - Seasoned: |

|

Toughness - Unseasoned: |

|

Toughness - Seasoned: |

|

Hardness - Unseasoned: |

1.9

|

Hardness - Seasoned: |

2.5

|

Durability

| Low | Moderate | Reasonably High | High | |

| (0 - 5 yrs) | (5 - 15 yrs) | (15 - 25 yrs) | (more than 25 yrs) | |

In-Ground: |

|

|||

| (0 - 7 yrs) | (7 - 15 yrs) | (15 - 40 yrs) | (More than 40 yrs) | |

Above ground: |

|

|||

| (0 - 20 yrs, usually < 5) | (21 - 40 yrs) | (41 - 64 yrs) | (More than 60 yrs) | |

Marine Borer Resistance: |

Lyctid Borer Susceptibility: |

Not Susceptible |

|---|---|

Lyctid Borer Susceptibility - Other: |

|

Termite Resistance: |

Resistant

|

Fire Properties

Sapwood colour pale yellow-brown and little different from the yellow-brown heartwood although wood from old trees tends to be darker. Grain and texture: grain generally straight but can deviate considerably from stem fluting or around knots from large branches of trees grown in open grown shelter belts or. The texture is fine and even with visible growth rings. Ray tissue gives the wood a lustrous appearance similar to that of hoop or kauri. The heartwood exhibits a fragrant spicy odour or ‘pencils’ similar to that of western red cedar.

Weatherboards, pergolas, landscaping, exposed rafters and beams (internal), shingles, tongue and grove panelling, flooring overlays, feature gates and fencing, slabs for kitchens and bar tops, shop fittings signs, tables, (use for furniture is comparable to radiata pine although the long term performance is adversely affected by the low hardness (c. 65% that of pine)), boat building, cabinet making, wood turning and carving, fence battens, stairways and balustrades, laminating, picture framing and joinery and firewood.

The wood saws, planes and works easily owing to its fine texture. It holds nails well; the gluing and painting properties are good. Bending properties are reportedly very poor.

Joinery

Panelling, Interior

Cladding, External