Overview

An eroded volcanic crater, off the Onewa Rd exit from Auckland's Northern Motorway. Onepoto Basin is home to a much discussed and awarded, marine-influenced footbridge.

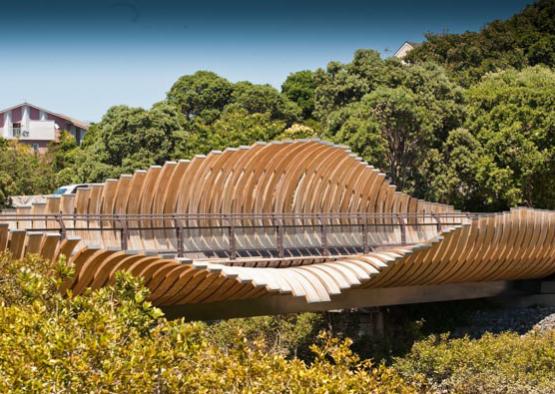

Designed as a fishbone metaphor, the bridge has become known to local residents as the 'wave bridge' – somewhat ironically as there is no surf in the area.

It is a visually striking, flowing structure spanning 46m, with seried laminated pine ribs unfolding and providing pedestrians with a sense of motion and the changing landscape as they walk along the bridge.

The brief from local council to designers and builders Beca Architects was to provide a functional structure to allow pedestrians to cross a tidal stream and stand of mangroves, which also offered a unique experience by incorporating architectural elements to create interest while blending into the surrounding landscape.

Their solution was a bridged walkway whose main visual features are curved timber glue-laminated ribs, geometrically arranged to create an undulating and unfolding sinuous form.

The Onepoto Footbridge was an urban design winner in the NZIA Auckland Architecture Awards and won the outdoor infrastructure category in the New Zealand Wood Awards.

Case Study courtesy of timber+DESIGN international magazine.

Structure

The complex organic form was derived through a succession of manipulations of geometry, beginning as a cylinder. Beca says the wave shape of the original concept was achieved by controlling the surface tension through a multiplicity of ordered nodes. Construction materials and techniques were then considered and introduced into the modelling process.

The intricate design of the undulating form of the bridge cladding was solved using a simple geometrical progression - by varying the lengths of the glulam ribs and only using two forms of rib.

The glulam supplier was involved early in the project to advise on optimum section sizes and radius options. With individual panels being 400 mm wide and 90 mm thick, straight members were manufactured first, then sliced into thinner layers and pressed into their curved shapes.

A complex series of gradients meant that each curved panel (about 150 in all) had to be made to precise dimensions and match the adjoining panel. Double-curved members were made for the central panels on the side facing a reserve, with a reversed folding curve to form a cascading lip.

The ribs also nicely conceal the concrete beam of the underlying structure and allow for the bridge to be completely camouflaged within the mangrove environment.

Exterior

Factors that influenced the choice of wood for the superstructure included: technical simplicity, allowing the architects to keep within the prescribed budget; weight; colour and visual warmth; flexibility and environmental fit. A bonus is the fact that timber is a low-carbon-emitting material compared with concrete or steel.

To combat potential long-term deterioration, each layer of lamination was preservative treated. All holes drilled in the wood were heavily protected with preservative.

In this coastal situation, the designers also had to eliminate the risk of chemical reaction between the timber and the individual galvanised steel brackets attaching the wood panels to the super tee. The solution was to use a synthetic rubber as the separation membrane.

Another challenge was dealing with the differential movement and tolerances between the various components. Dry-packed steel shims, washers and adjustable bolts were the solution.

Beca says civil engineering projects rarely work to such tight tolerances. "There was an important role in informing the contractors of design intentions and raising awareness of the need to understand the vagaries inherent in the use of a live material [radiata pine], whose behavior - once released from the jig - could be less predictable than other materials.