Publications

TBC

Timber’s equilibrium moisture content (EMC) varies across coastal, inland, and tropical climates. Builders often underestimate the seasonal effects on timber stability, particularly where elevated moisture levels coincide with decay or corrosion risk. Understanding these regional influences is crucial for specifying suitable timber species, treatments, and detailing strategies.

TBC

Timber’s equilibrium moisture content (EMC) is not constant. It changes with geography, seasonal humidity, and site exposure. A piece of timber stored near the coast will stabilise at a higher EMC than the same timber kept inland, while tropical climates can expose timber to both high humidity and rapid fluctuations.

When EMC differences are ignored, installed timber may move or distort as it adjusts to its environment. Floors can cup or gap, framing can twist, and joinery may misalign. Recognising these variations—and the corresponding climatic decay and corrosion risks—is essential for achieving dimensional stability and durability.

This article highlights how climate influences EMC across Australia, with maps illustrating the country’s decay hazard and corrosion exposure zones, as defined in WS05 Timber Service Life Design.

Equilibrium Moisture Content (EMC) describes the point at which timber no longer gains or loses moisture because it has reached balance with the relative humidity and temperature of its environment. In Australia, this balance varies considerably depending on geography.

Even within a single project, micro-climates influence performance. A shaded verandah may maintain a stable EMC, while nearby exposed cladding equilibrates closer to outdoor humidity.

Table 1: Climate-Based Moisture Considerations

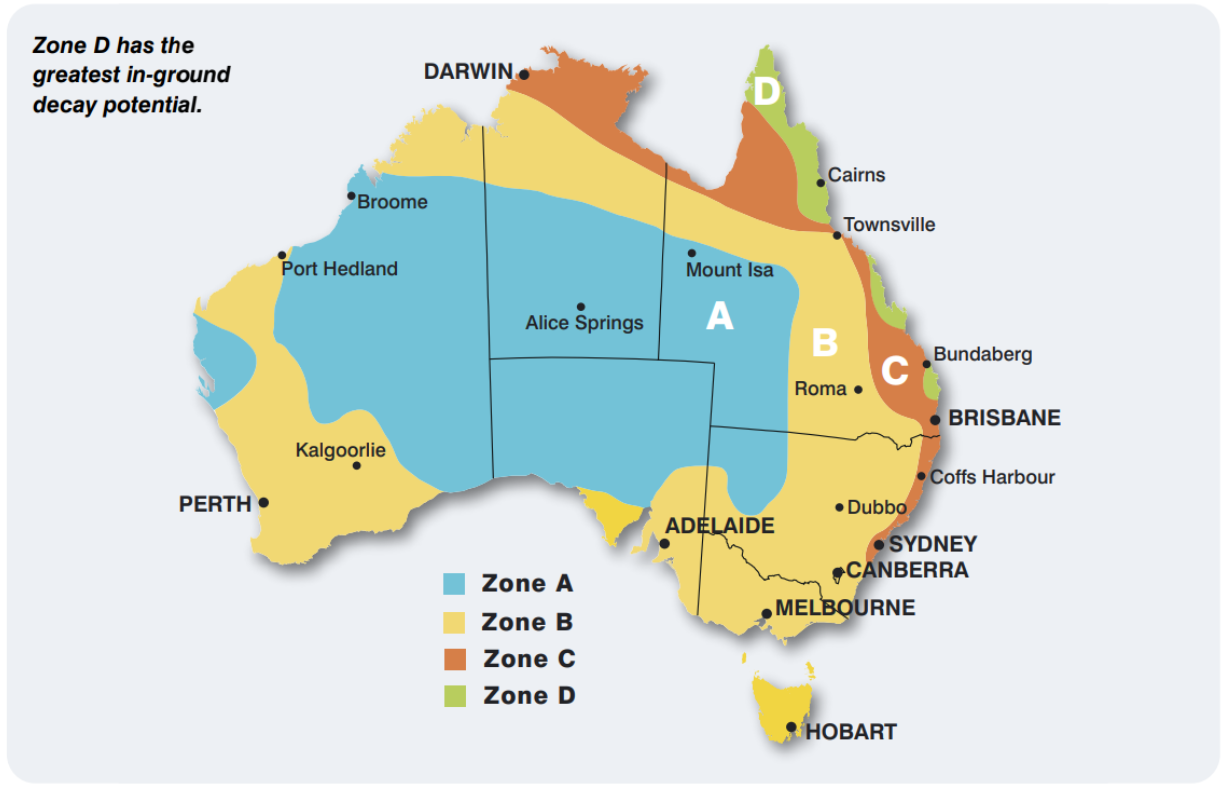

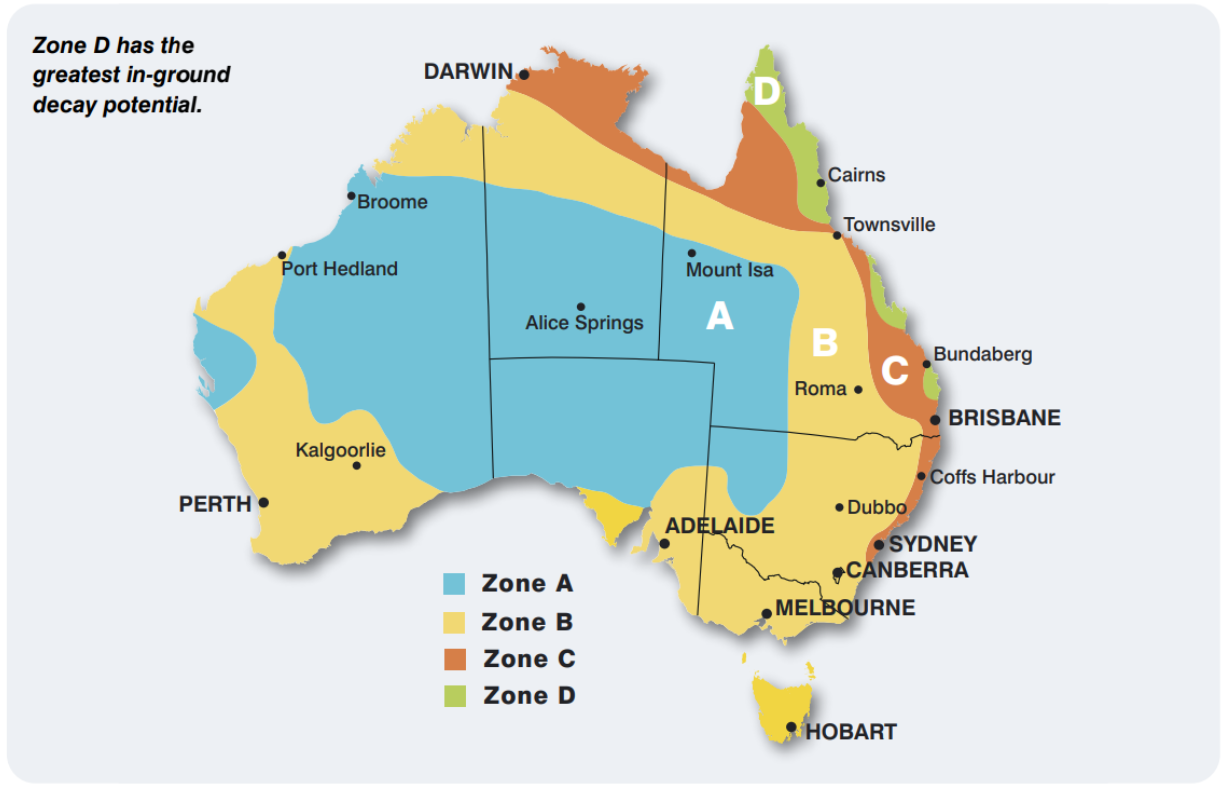

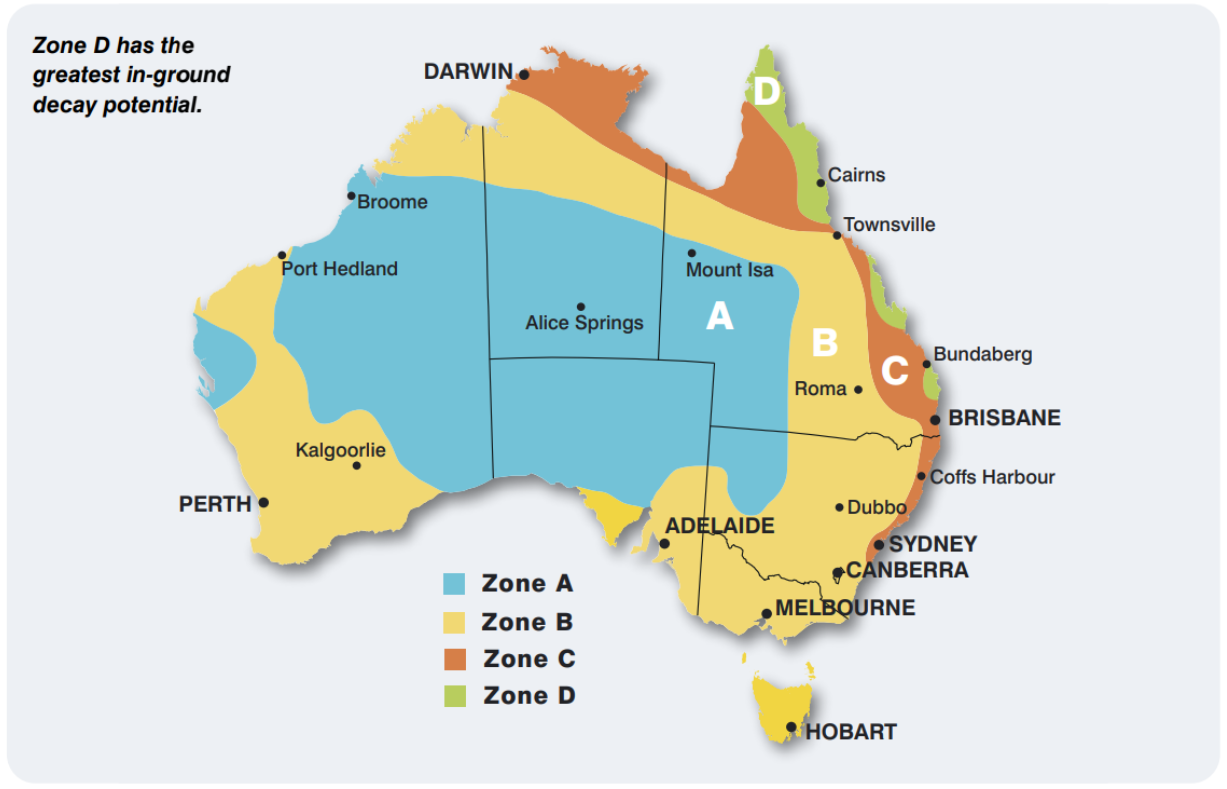

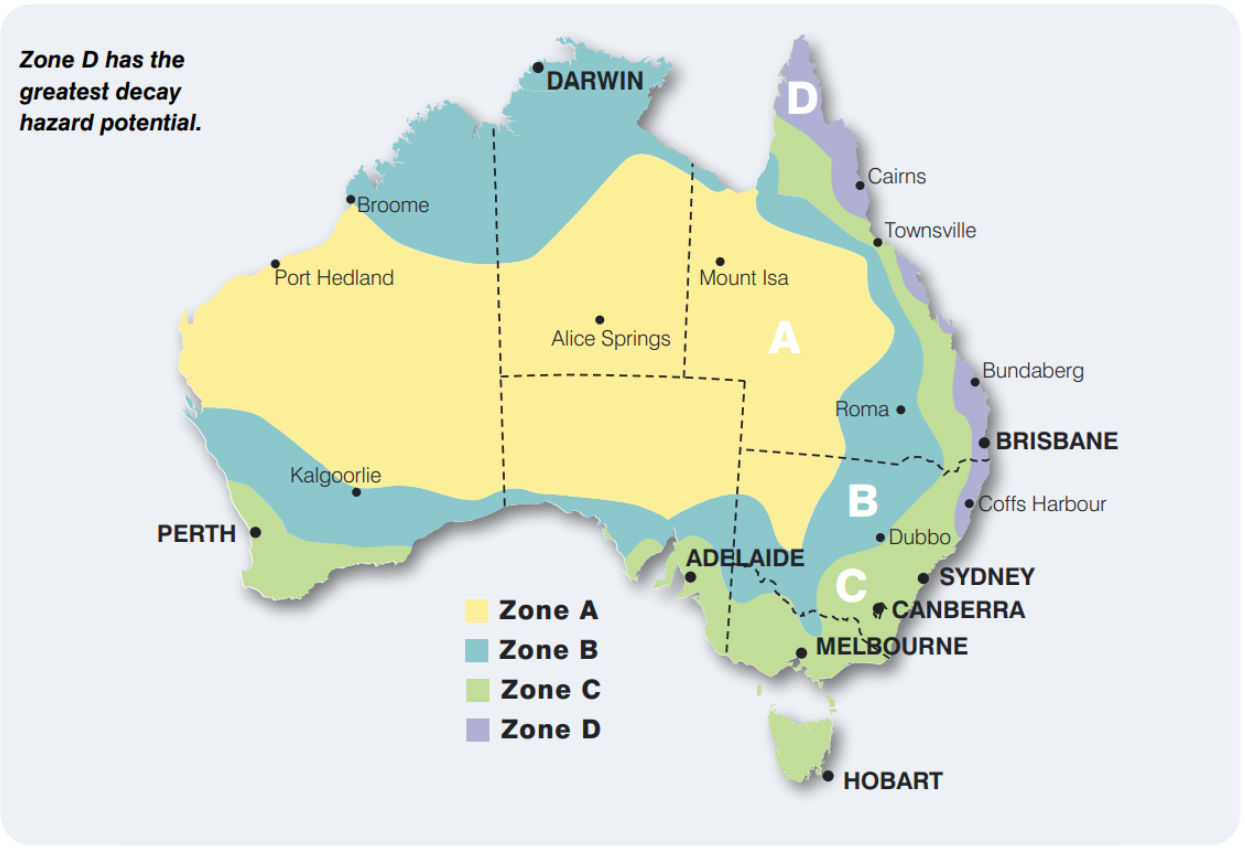

Australia’s diverse climates create distinct combinations of moisture exposure, decay potential, and corrosion risk. These are captured in the climatic hazard maps reproduced below.

Seasonal humidity changes can significantly alter timber’s EMC, and with it, the performance of building elements. Even when average EMC values are known for a region, short-term swings between wet and dry periods cause timber to expand and contract in cycles.

Proper handling and preparation of timber before installation can greatly reduce the risks associated with regional and seasonal moisture variations.

Timber performance is inseparable from its context. Australia’s diverse climatic conditions generate distinct combinations of humidity, rainfall, salt exposure and temperature that influence both equilibrium moisture content (EMC) and long-term durability.

This section provides national mapping that classifies these variables into hazard and corrosion zones. They offer a visual reference for understanding where EMC, decay and corrosion risks overlap.

This map classifies the decay potential for timber in ground contact, based on rainfall frequency, temperature and soil moisture retention.

Figure 1: In-ground decay hazard zones

Above-ground elements experience repeated wetting and drying from rainfall, humidity and wind-driven moisture. This exposure directly affects EMC cycling, surface checking and coating life.

Figure 2: Above ground decay hazard zones

Moisture, temperature, and exposure conditions vary dramatically across Australia, shaping how timber behaves in service. The hazard and exposure maps show that equilibrium moisture content, decay potential, and dimensional stability are not fixed properties of a species or product, they are environmental outcomes.

By anticipating these variations, and applying best-practice measures such as ventilated storage, acclimatisation, and protective finishes, builders and designers can significantly improve the stability and service life of timber products.

This content should be read in conjunction with the related sub-articles on Moisture Measurement and Durability Detailing, to provide a complete picture of how moisture influences timber performance in Australian conditions.

Key implications for practice include:

Although this page focuses on moisture and decay, the same climatic forces also accelerate metal fastener corrosion, particularly along coastal and tropical belts. For guidance on fastener performance and protective measures, refer to the Fasteners and Connectors sub-page.

Together, these resources form an integrated understanding of how Australia’s climate zones govern timber durability, from biological decay in the ground, to movement and finish wear above ground, to corrosion at fixings. Recognising and designing for these regional patterns ensures timber structures remain stable, safe and visually consistent throughout their service life.