Publications

TBC

Timber's durability in service is not determined by species or treatment alone. Good detailing is necessary to ensure timber durability, allowing timber to shed water, dry out, and avoid becoming a moisture reservoir. This page explains the design principles and construction details that protect timber from early decay, and support NCC durability compliance.

TBC

Durability failure most often arises from:

Water must be diverted away from timber surfaces at every opportunity.

End grain absorbs water up to 10× faster than face grain - it must always be sealed, flashed, or protected by detailing. Best practice includes:

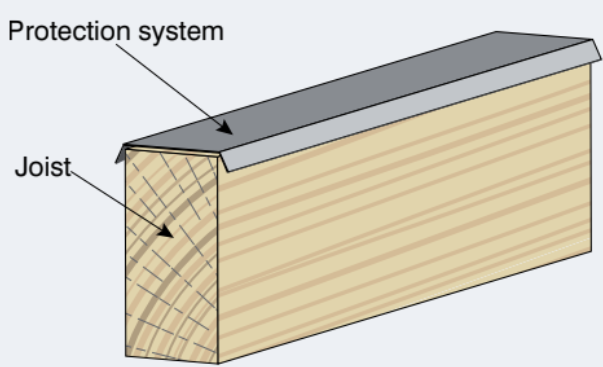

Horizontal members such as joists and beams are also highly exposed. Protective measures include:

Figure 1: Capping protects top and end grain of projected beam

Figure 2: Diagram of timber element capping to protect against thje effects of exposure

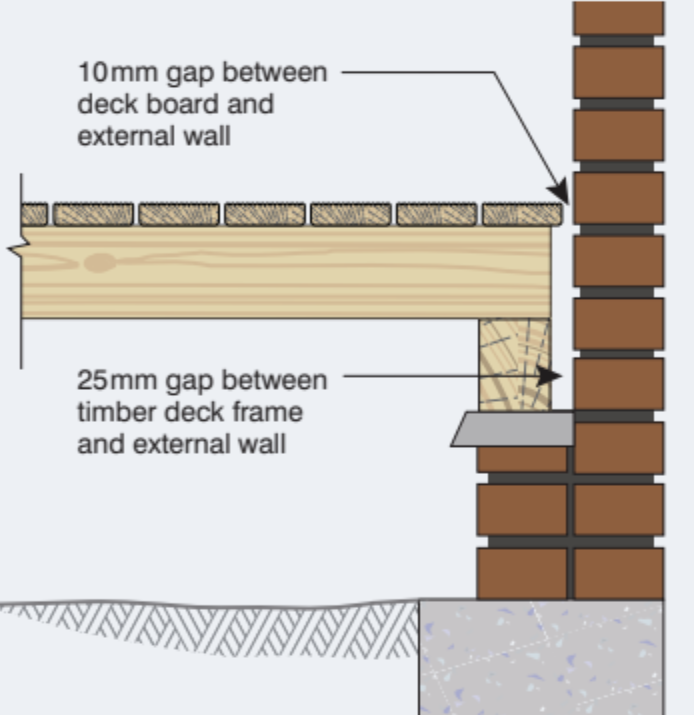

Junctions between timber members are the most likely failure point. All joints must be:

Figure 3: A well-ventilated, free-draining post support

Figure 4: Gaps between decking and brickwork for ventilation and expansion

For unseasoned timber in heavy construction (e.g. wharves, industrial decks):

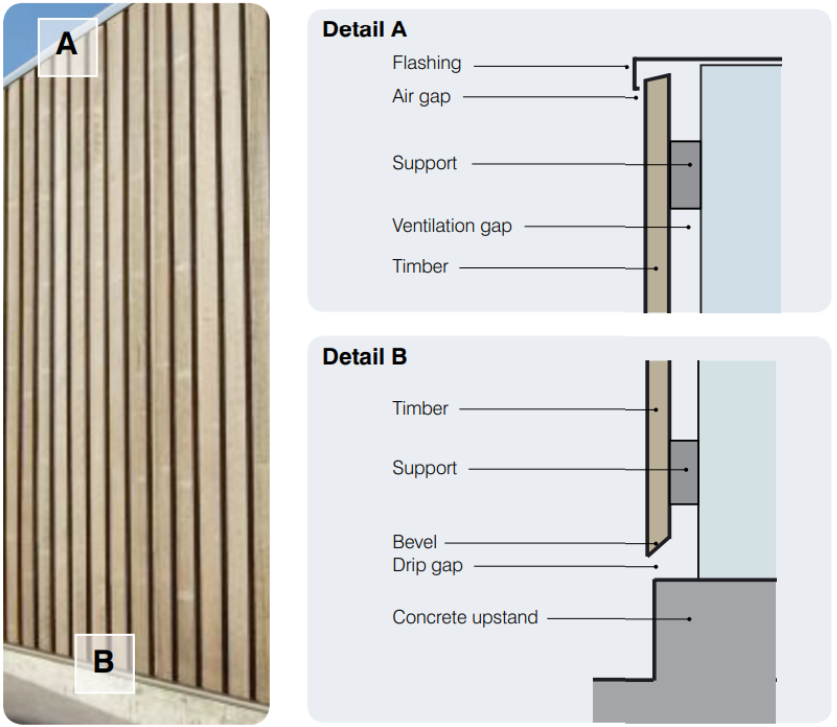

Airflow is critical for drying any timber that gets wet. Common cavity detailing includes:

Figure 5: Gaps in a facade plane for ventilation

Durability is often compromised by small details:

Timber should not be in prolonged contact with moisture-retentive materials such as:

Durability depends on what you can inspect, maintain, and replace. Key strategies: