Publications

TBC

Exterior timber finishes serve both aesthetic and protective roles. They shield timber from moisture ingress, UV degradation, staining, and surface checking - all of which directly affect durability and service life. Finishes protect timber from weathering, reduce moisture movement, and enhance appearance. While finishes do not make timber waterproof, they slow the rate of wetting and drying, which reduces cracking, splitting, and decay. Correct application and regular maintenance of finishes is essential to achieving the intended service life of timber in external environments.

Whether the goal is a natural appearance or long-term colour retention, the choice of finish must consider:

TBC

Some designers prefer timber to weather naturally, but this choice comes with performance trade-offs.

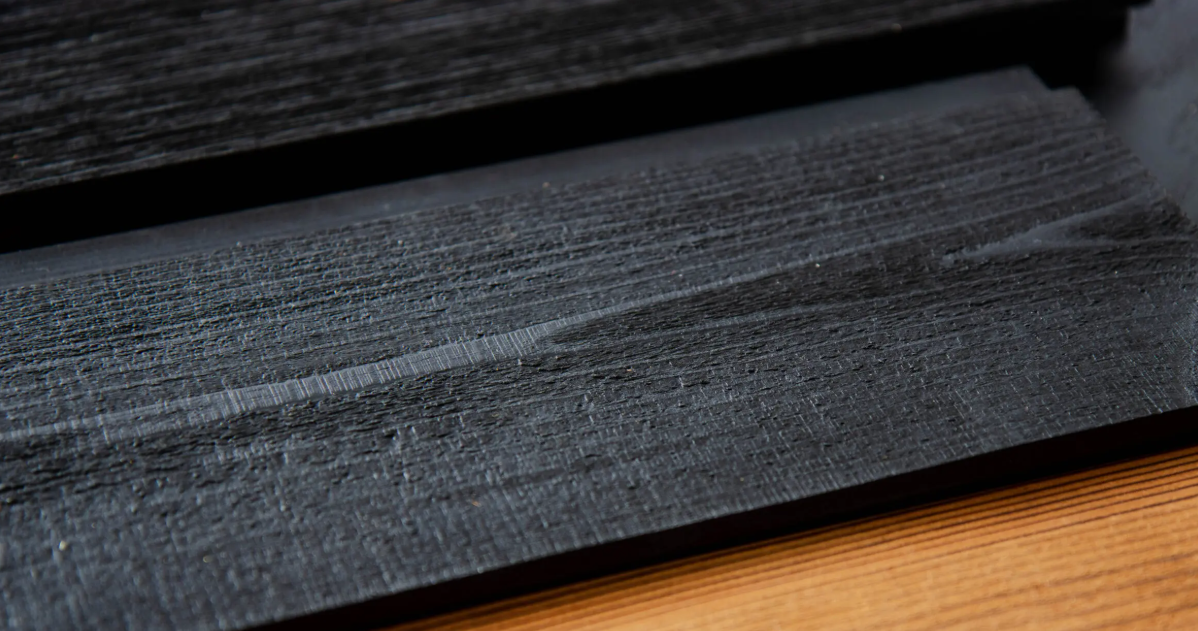

The chart below provides a good first approximation for a preservative treatment pathway:

Figure 1: Preservative treatment pathway chart

Notes:

Factory-applied finishes offer better consistency and quality control, but require careful handling and protection during transport and install.

No coating lasts forever. All finishes will eventually degrade under UV and moisture cycling, particularly on exposed horizontal or north-facing surfaces.

Figure 2: Typical maintenance schedule for various treatment types

🛈 Always clean surfaces prior to recoating. For film-forming systems, light sanding may be required to avoid peeling.

Film-forming finishes, such as paints, clear surface coatings and heavy- bodied stains appear as a layer on the surface of the timber, visually creating a smooth surface and do not penetrate significantly into the surface of the timber. Experience has shown that these finishes have, at times, been associated with premature decay, Success will require very regular maintenance to ensure there is no break in the film, however slight, and also the removal of the coating between applications.

Decay under a film finish:

Figure 3: Decay under a film-forming treatment. Stubbersfield Newsletter September 2025

Good detailing and timber fibre selection:

Figure 4: Good detailing and timbre fibre selection. Stubbersfield Newsletter September 2025

Coatings will fail faster if timber is poorly detailed. Best practices include:

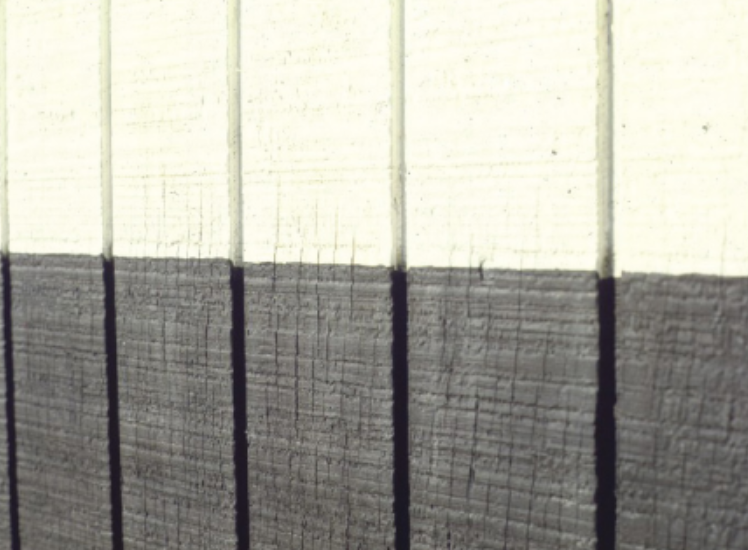

Figure 5: Light and dark coatings in a durability study

Light coloured finishes are preferred to dark colours as they are less prone to checking and distortion due to intense cycles of heating and cooling.

For new applications a Slip- resistant surface can be achieved by installing a board with a rough sawn, lightly sanded/brushed face. For existing applications, the face can be roughened with a specialised brushing process. Alternatively, add a slip-resistant additive to the deck finishing product. Some coating manufactures have products with anti-slip particles already included, while others have particles that can be added to standard coating products. Refer to the coating product manufacturer for more information. However, experience has shown that this will require a very high level of maintenance as noted above under film forming finishes. For an in depth discussion refer to Guide #48 - Slip Resistance and Wood Pedestrian Surfaces.

Preservative-treated timber may affect the performance of certain finishes:

Always check manufacturer datasheets for:

Maintenance requirements vary by finish type, exposure, and orientation:

Regular inspection and cleaning prolong the service life of finishes. Remove dirt, debris, and fungal growth to maintain surface protection.