Publications

TBC

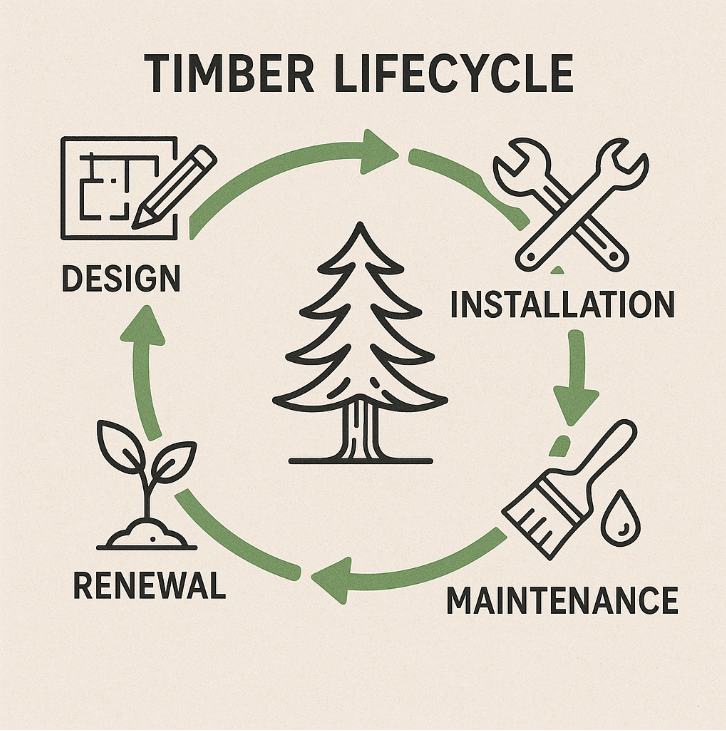

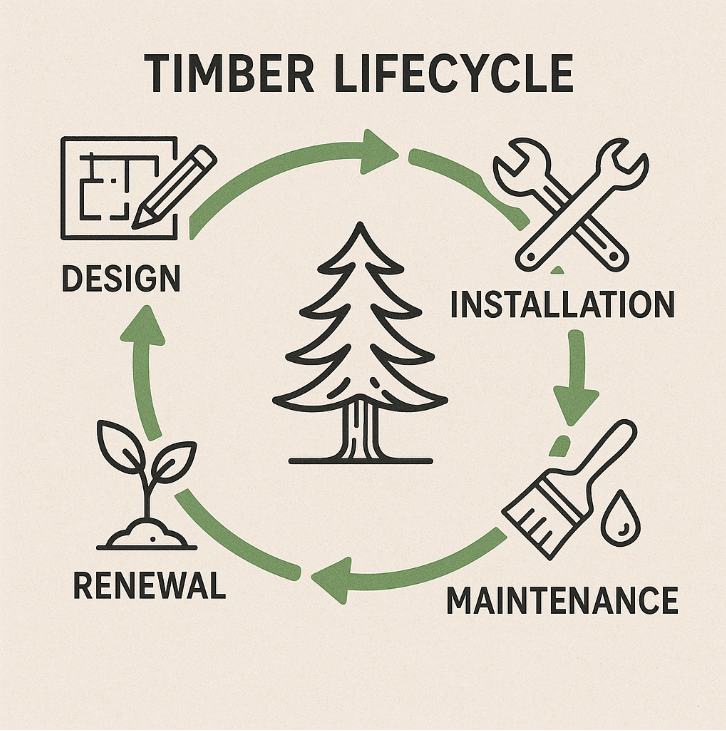

Timber is a natural material that changes over time. Even when detailed correctly and treated or coated, external timber elements require regular inspection and maintenance to achieve their intended service life. Proactive maintenance helps detect early signs of deterioration and reduces the likelihood of costly repairs or premature replacement. Timber's durability is not a "set-and-forget" outcome, it is the result of ongoing care, planned inspection, and preventative maintenance. The NCC requires that building elements remain “fit for purpose” over their design life, which depends on:

This sub-page outlines best-practice maintenance strategies to help designers and asset managers meet those requirements and ensure long service life.

TBC

The most effective maintenance strategies begin at the design stage. Key considerations include:

Tip: Where access is limited (e.g. eaves, upper storeys), use long-life finishes or overdesign for added protection.

Caption: Planning realistic maintenance tasks ensures timber continues to perform over its life.

While coatings are covered in detail in the Exterior Timber Finishes sub-page, some maintenance notes are worth repeating:

Note: Avoid applying new coatings over dirty, oily, or degraded surfaces. Surface preparation matters.

Design for disassembly allows individual parts to be replaced without dismantling the entire structure.

Where full replacement is needed:

Certain conditions shorten service life even with durable detailing:

Proactive strategies provide the greatest confidence in achieving design life.