Publications

TBC

This page introduces the range of timber products and structural systems used in construction. It provides a foundation for understanding the types of timber products and structural systems available, their applications in different building typologies, and key performance considerations.

Timber is lightweight, strong for its weight, and renewable, making it an increasingly preferred material for modern construction. With advances in engineered wood products (EWPs) across a range of component types, species, and performance aims, timber has applications across a huge swathe of our built environment.

Ultimately all timber building products are derived from the forest, and fall broadly into three categories: Sawn based, Veneer based, and Strand based:

This is a broad outline of the timber products available. More are being developed every day.

TBC

Timber building products fall into three broad categories: Sawn based, Veneer based, and Strand based. Each has different factors in supply and composition. However, they can be used to create products that perform the same functions. In this page we will discuss the three categories and what it means to use them in our built environment.

Sawn timber refers to solid wood milled directly from logs into structural sections. It is widely used for framing, cladding, decking, and joinery. Sawn products can be recomposed into larger members, such as finger-jointed boards or mass timber laminations, removing characterisation like knots.

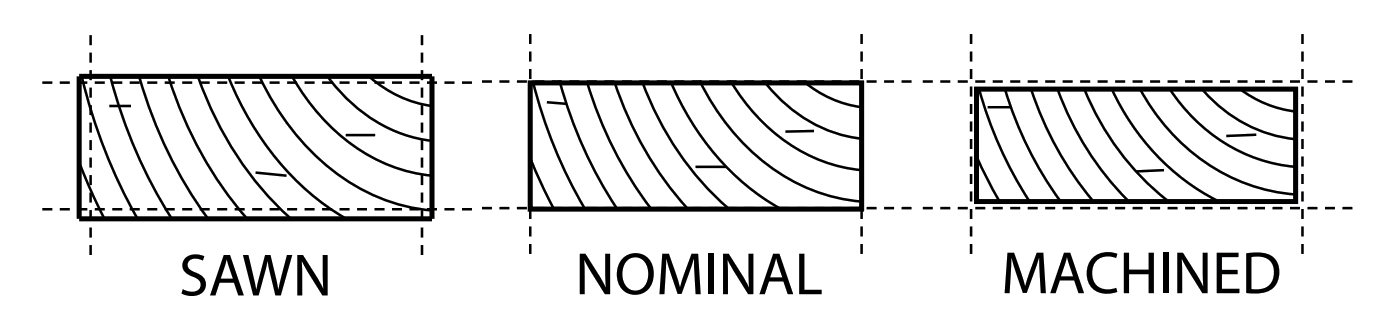

Sawn timber is commonly machined to produce a specific profile or finish.

Dressing refers to machining that improves surface finish and dimensional accuracy, but does not imply profiling. All dressed timber is machined, but not all machined timber is dressed.

Tip: Pay attention to the moisture content of your sawn timber and the condition of the supply stock. This helps you minimise movement in service and get more reliable performance out of each element.

Figure 1: Sawn timber profiles (WS TDG 46 p71)

Sawn timber products are used as-is, treated, and recomposited into a staggering variety of products including:

Landscaping or foundations in rounds or dressed sections

Lightweight timber framing (treated sawn timber)

Glued-laminated components

Cross-laminated components

Veneer-based timber products are manufactured from thin layers of wood, typically 3–6 mm thick. Veneers are produced by peeling logs in a continuous rotary process, delivering exceptionally high recovery from the raw resource. These veneers are bonded together using adhesives, heat and pressure to form billets or panels that are then sawn or cut into final products. Because the timber is recomposed from thin layers, veneer-based products offer excellent dimensional stability and highly consistent mechanical performance. Most LVL is produced from softwood species, although hardwood LVL is also available. If you’re new to engineered wood, the plywood family is usually the most familiar entry point.

Some veneers are used purely for aesthetics, allowing designers to showcase scarce or high-value decorative species in an efficient way.

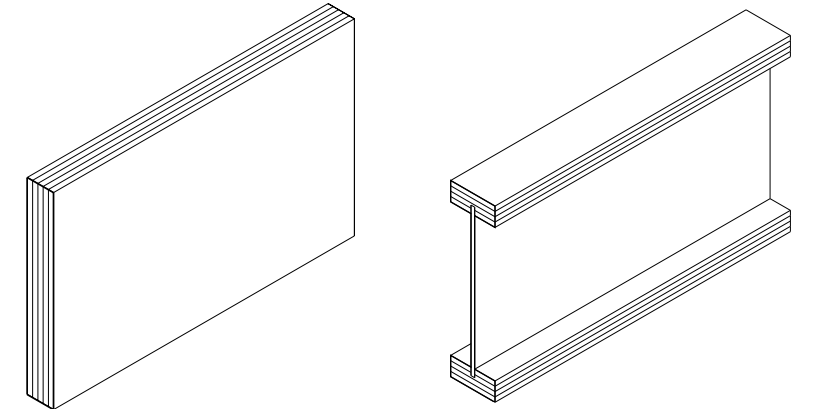

Figure 2: Veneers combined into a larger section

Veneer products are used as-is, treated, and recomposited in a staggering variety of products including:

Visual products such as decorative linings/plywood, and flooring.

Structural products such as Laminated Veneer Lumber (LVL), structural plywood, and I-Beams.

Large elements, such as Massive Ply Panels or within other glued elements for extra strength.

Strand-based products involve a high degree of fibre recomposition. Timber is shredded into controlled strands and re-formed using adhesives, orientation control, heat and pressure. This approach produces highly homogenous products with strong, predictable performance characteristics. Strand products also achieve very high yield from the raw log and make efficient use of a wide range of fibre types, improving overall resource utilisation.

The most common strand product in the Australian market is Oriented Strand Board (OSB). Other products made from long strands in heavy structural components are Parallel Strand Lumber (PSL) and Laminated Strand Lumber (LSL) which can have strands in the same orientation, or varying orientations. Neither of these products are produced within Australia, however there is availability through importers. Innovators are exploring the fabrication of even larger elements such as mass timber stye Cross-Laminated Strand Lumber (CLSL) creating truly huge building products from these small strands.

Assemblies bring together sawn, veneer and strand-based components into more complex systems. These may include prefabricated wall, floor and roof cassettes, structural frames, volumetric modules or hybrid mass-timber systems. Assemblies of various kinds bridge between individual timber product types and complete building systems, including:

Prefabricated light-timber framing

Mass-timber floor and wall systems

Multi-material hybrid assemblies

High-performance façade systems

Engineered connectors and fasteners forming part of the overall system design

Suppliers across the timber sector engage with Modern Methods of Construction (MMC) in different ways depending on their materials, machinery, logistical capacity and commercial positioning. The MMC Definition Framework categorises modern construction into seven categories. These categories provide a useful lens for understanding why one supplier may choose to produce a simple sub-assembly while another may invest in full volumetric modular delivery. Below is an overview of the seven MMC categories followed by an explanation of the key factors influencing supplier choices.

Category 1 – Pre-manufactured 3D primary structural systems

(Volumetric modules, pods, bathroom pods, plant rooms.)

Category 2 – Pre-manufactured 2D primary structural systems

(Panels, CLT, framed wall cassettes, floor cassettes.)

Category 3 – Pre-manufactured components, assemblies and sub-assemblies

(Stair units, roof cassettes, I-joist floor systems, trussed rafters.)

Category 4 – Additive manufacturing and 3D printing

Category 5 – Non-structural sub-assemblies and components

(Services risers, façade units.)

Category 6 – Traditional building product innovations

(Improved fixings, digital cutting, novel connectors.)

Category 7 – Site process improvements

(Digital workflows, onsite robotics, improved QA processes.)

Most timber suppliers operate within Categories 2, 3, 5 and 6, with a smaller number engaging in Category 1 due to capital intensity.

Sawn, veneer and strand products differ mainly in fibre recomposition, which determines consistency, strength, dimensional stability and typical applications.

Sawn timber is versatile, familiar and widely available, but varies with species and defects; used across framing and simple assemblies.

Veneer products offer high consistency, long spans and excellent stability due to layered construction.

Strand products are highly resource-efficient and homogenous, suited to sheathing, bracing and engineered components.

Assemblies combine these products into systems ranging from trusses and cassettes to panelised mass timber and modular units.

Supplier choices within the MMC framework are shaped by plant investment, workforce skills, logistics, digital capability, risk appetite and market demand.

Different product types naturally align with different MMC categories, with most Australian suppliers operating in Categories 2–3 (panelised or sub-assemblies).

Performance characteristics such as moisture resistance, fire safety, and durability are covered in detail elsewhere.

Timber construction is rapidly evolving, bridging traditional techniques with modern engineering innovations. Choosing the right structural system ensures code compliance, cost-effectiveness, and long-term performance in timber buildings.

Timber construction systems range from lightweight framing to large-format mass timber and hybrid assemblies. The choice of structural system depends on building type, height, desired speed of construction, and performance requirements such as fire resistance, acoustic separation, and thermal efficiency.

This section introduces the primary timber systems in use across Australia and provides links to detailed design and compliance guidance.

Overview

Lightweight timber framing is the dominant construction method for Class 1 residential buildings: housing and terrace housing. Framing typically uses MGP or F-grade softwoods, assembled into walls, floors, and roof trusses.

Features

Figure 1: Timber Framed Construction (Speedpanel and USG Boral) (WS TDG 01 p5)

Overview:

Mass timber refers to any timber element with a minimum cross-section thickness ≥75 mm. This includes products like CLT, Glulam panels, and thick LVL, which form structural walls, floors, or roofs. Mass timber systems can be used across all building classes, and has been used successfully in Australia in domestic houses, commercial offices, industrial warehouses, residential apartments, hotels, resorts, and civic buildings.

Panel-Based Systems

CLT and other panelised systems are used for loadbearing walls, floors, and roofs. They are dimensionally stable and suitable for prefabrication.

Post-and-Beam Systems

Massive Glulam or LVL members are used in grid layouts to support long-span roofs and open-plan interiors.

Figure 2: CLT Construction (Strongbuild) (WS TDG 16 p7)

Overview

This system uses discrete vertical and horizontal members (columns and beams) to form a structural frame. It is ideal for buildings requiring long spans or flexible internal layouts, such as offices, halls, or commercial tenancies.

Features

Figure 3: Post and Beam construction (Chifley Business Park - Goodman)

Overview

Prefabricated systems use off-site manufacturing to deliver walls, floors, and even complete room modules (volumetric units). This approach improves quality control, reduces site labour, and shortens construction timelines.

System Types

Figure 4: Prefabricated timber walls being assembled by Modscape + Modbotics automation

Timber’s lightweight nature, prefabrication potential, and fire-resistant capabilities make it an ideal material for modern, sustainable construction across all major building classes.

Timber construction systems are now used across nearly all NCC building classes-from detached houses to mid-rise apartments and large-span commercial buildings. Each building type places different demands on timber systems in terms of structure, fire resistance, durability, acoustics, and moisture control.

This section outlines the most common structural approaches by building class, with links to deeper design guidance.

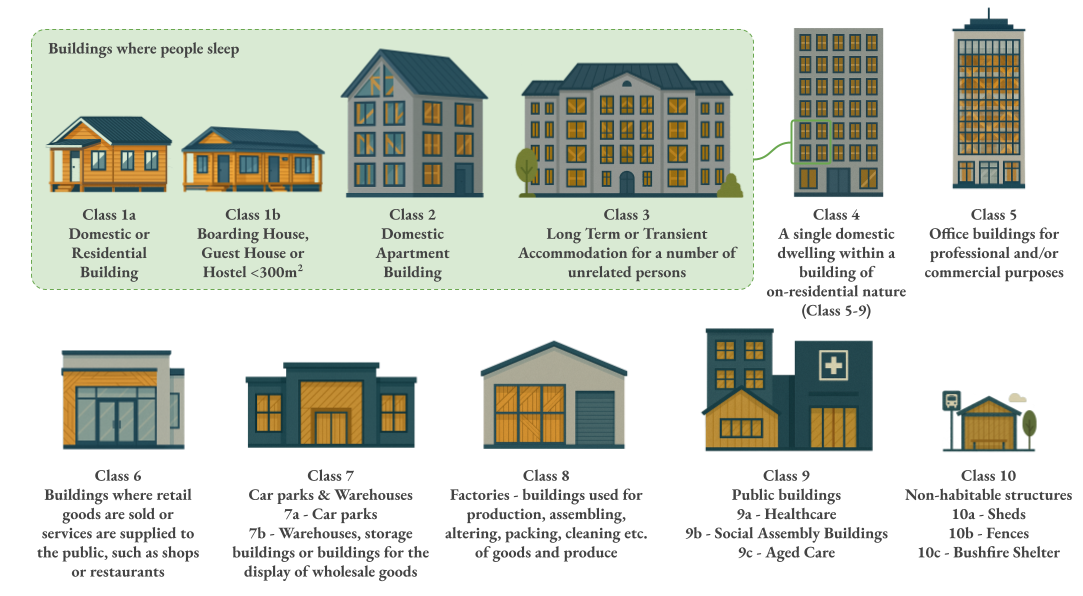

What are the building classes?

Figure 1: Building Classes (NCC)

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Typical systems:

Advantages:

Performance:

Understanding timber’s structural, fire, acoustic, and environmental performance ensures safe, compliant, and long-lasting timber buildings in modern construction.

Timber is a high-performance construction material and its behaviour under load, moisture, fire, sound, and thermal stress must be well understood and carefully managed. This section provides a concise overview of key performance areas in timber design and construction.

Each topic summarised here is explored in greater technical depth on dedicated subpages.

Overview

Timber products-especially engineered products like CLT, LVL, and Glulam-offer excellent strength-to-weight ratios and can be used for both short-span and long-span structural systems.

Design Considerations

Overview

Timber is hygroscopic-it absorbs and releases moisture in response to humidity, rain, vapour diffusion, and condensation. Moisture is a defining factor in long-term serviceability.

Design Considerations

For more information see the Moisture Guide and the Durability Guide

Overview

Timber-especially mass timber-performs predictably in fire due to its insulating char layer. Modern detailing allows timber buildings to meet Fire Resistance Levels (FRLs) up to 90 or 120 minutes.

Design Considerations

Overview

Timber’s low mass can lead to sound transmission unless layered and decoupled effectively. Acoustic detailing is essential in multi-occupancy buildings and schools.

Design Considerations

Overview

Timber provides natural insulation and enables high-performance thermal assemblies. It supports net-zero energy goals with reduced thermal bridging and high airtightness.

Design Considerations

By integrating engineering, protective detailing, and compliance strategies, timber buildings can achieve exceptional durability, fire safety, sound insulation, and energy efficiency, ensuring long-term functionality and sustainability.

Timber buildings rely on a diverse array of connection systems to ensure strength, stability, and serviceability. From traditional joinery to modern engineered fasteners, the right connection method depends on the product type, structural system, and exposure conditions.

This section outlines the main categories of timber connections and how they’re applied across different building systems. More detailed design and fabrication guidance is provided in linked subpages.

Overview

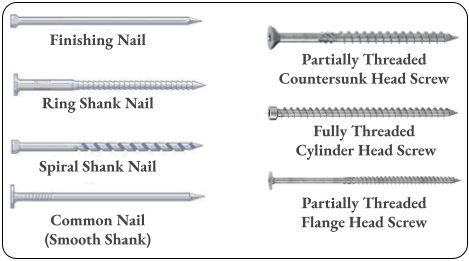

Mechanical fasteners are the most common connection type across light timber framing, engineered wood, and mass timber systems. They provide structural fixity, ease of installation, and flexibility on site.

Applications

Design Considerations

Figure 1: Some common types of nails and screws

Overview

Metal connectors provide increased load-carrying capacity and can simplify assembly in both light and heavy timber systems.

Applications

Figure 2: Gang-nail plate (ITSCP Offsite)

Figure 3: Joist hanger (Victorian Timber & Building Supplies)

Figure 4: Angle Bracket (Simpson Strong-Tie)

Figure 5: Dowel Connector (F. Solarino et. al.)

Performance Notes

Overview

Adhesives are used extensively in engineered wood products and increasingly in panel-based connections. They enable strong, invisible joints and improve air-tightness and vibration performance.

Applications

Considerations

Overview

Although less common in commercial buildings, traditional joinery techniques are still relevant in architectural projects, restoration works, and dowel-laminated timber (DLT) systems.

Examples

Advantages

Overview

Prefabricated timber elements are precision-manufactured off-site and assembled rapidly on-site with pre-defined connection details. Connection accuracy and sequencing are critical for speed and performance.

Key Elements

Assembly Considerations

Timber connections are essential for ensuring structural strength, fire compliance, durability, and construction efficiency. Understanding the right connection method for each timber system enables safe, cost-effective, and long-lasting timber buildings.