Even well-specified timber products can underperform if fabrication, handling, or on-site modification is not executed well. This section outlines the key fabrication principles needed to maintain material integrity, alignment with documentation, and performance expectations during and after construction.

Manufacturing and Fabrication of Engineered Products

Engineered wood products (EWPs) such as Glulam, LVL, CLT and plywood are manufactured under controlled conditions. Their performance depends on factory precision and the preservation of quality during transport, storage, and installation.

Key Considerations

- Bond type must match exposure class:

- Type A (fully waterproof, e.g. for Glulam in external structures)

- Type B or C (for interior-only use)

- Tolerances must be respected for length, squareness, camber, and bow

- Finish level (A, B, or C grade) affects acceptability of surface variation

- Grain direction in sheet products (e.g. plywood) influences stiffness and appearance in visible applications

Do not cut across adhesive bond lines, protective coatings, or laminated sections without supplier guidance.

Figure 2: 3 layer CLT panel after pressing (WS TDG 16 p5 XLam Australia)

See: [Handling of CLT, LVL, and Glulam Products]

See: [Structural and Visual Tolerances Guide]

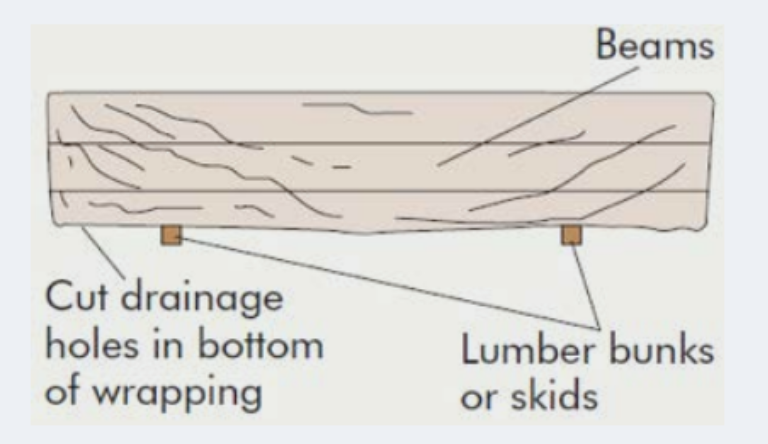

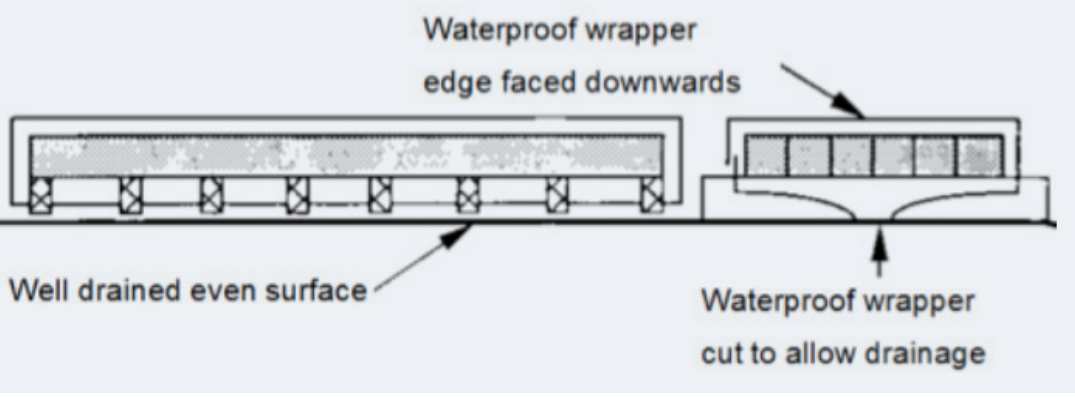

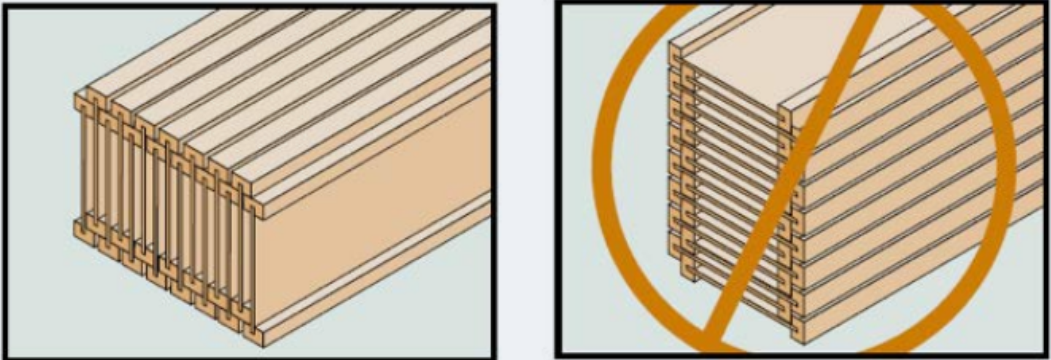

On-Site Handling, Storage, and Protection

Timber elements-particularly engineered and coated components-are highly susceptible to damage during site handling.

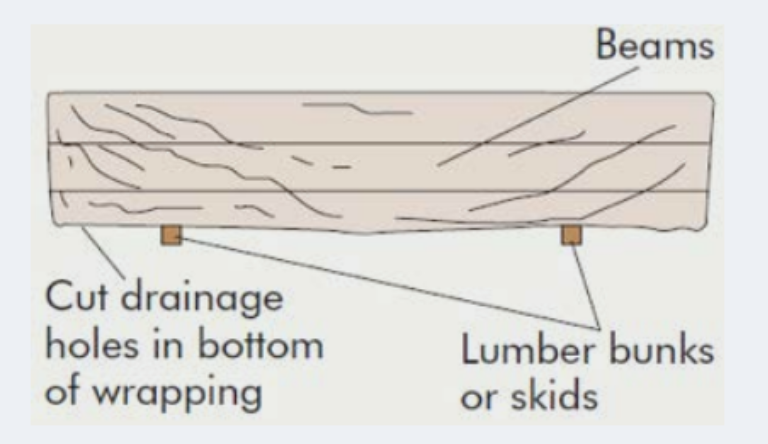

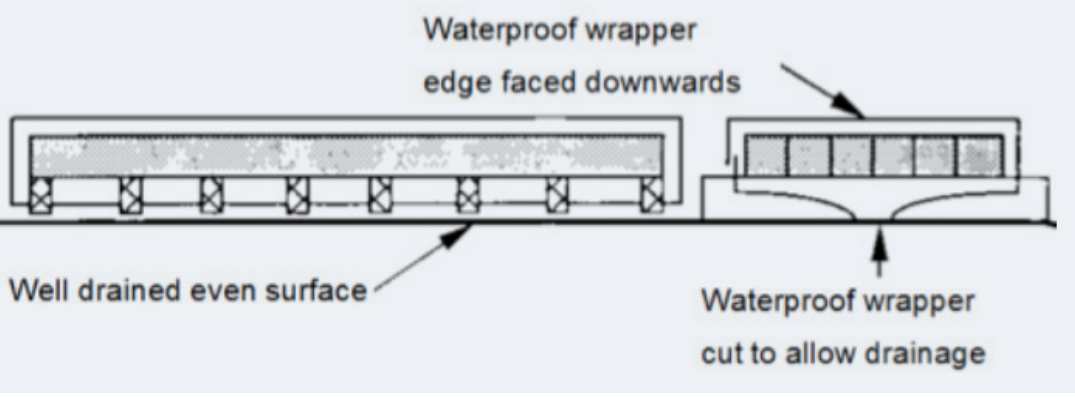

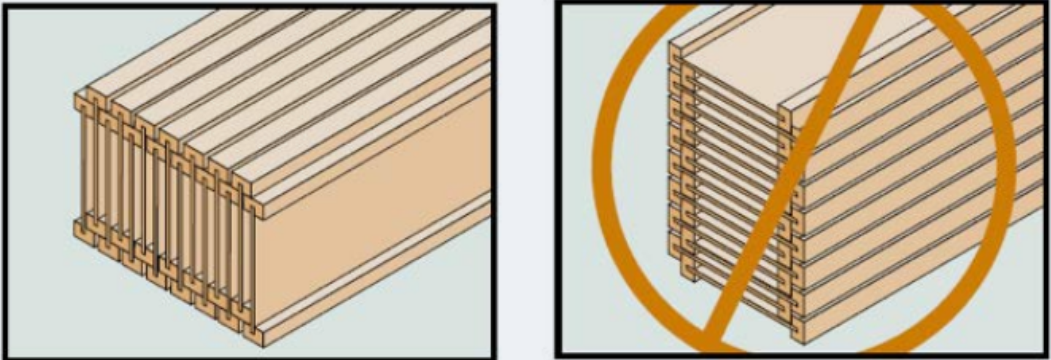

Storage Guidelines

- Store timber off the ground on flat, drained bearers

- Use breathable covers (e.g. woven wraps) to protect from UV and rain

- Avoid using impermeable plastic that can trap condensation

- Stack by type and length to reduce searching and restacking damage

Handling Notes

- Use spreader bars or lifting rigs for large Glulam and CLT elements

- Avoid point loads and excessive cantilevering

- Lift panels flat and ensure lifting eyes or plates are factory-approved

Moisture protection during handling is critical. Wetting before enclosure increases risk of mould, delamination, and fastener corrosion.

Figure 3: Stacking timber clear off the ground by skids (WS TDG 36 p8)

Figure 4: Site storage of Glulam (WS TDG 36 p8)

Figure 5: Storage of I-Joist Beams (WS TDG 36 p8)

See: [Moisture Management During Construction]

See: [Temporary Protection and Site Sequencing]

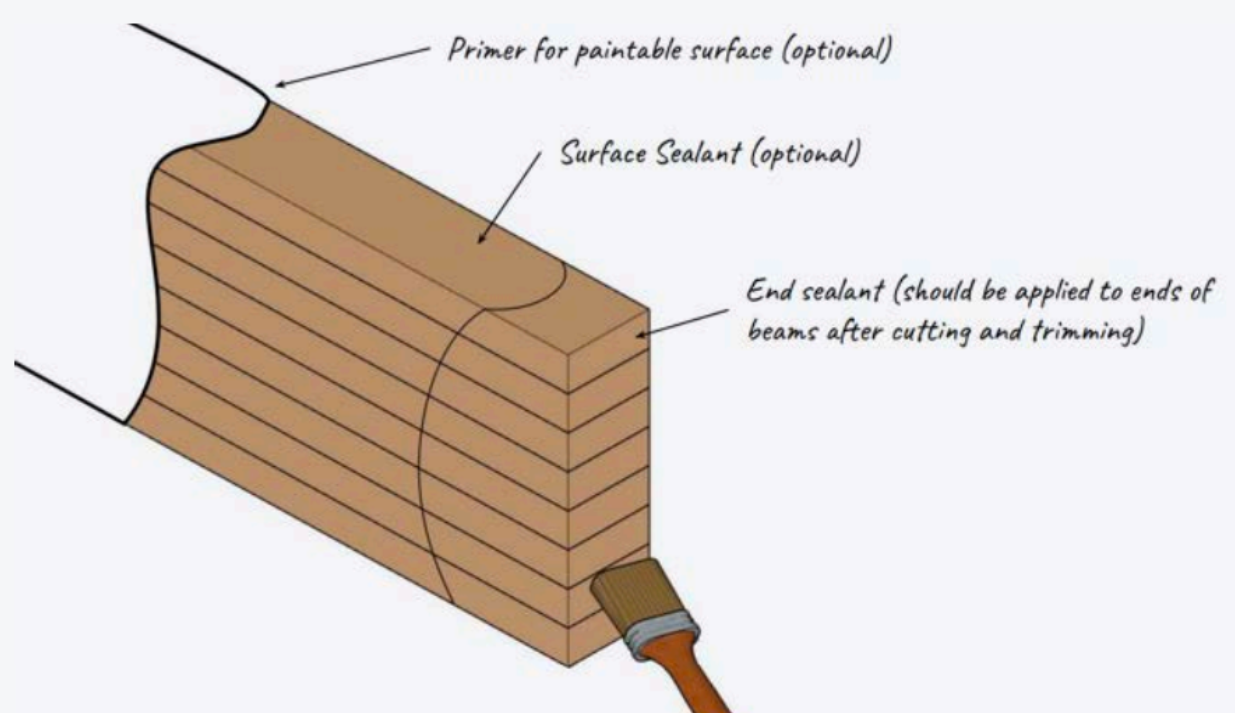

Cutting, Drilling and Site Modification

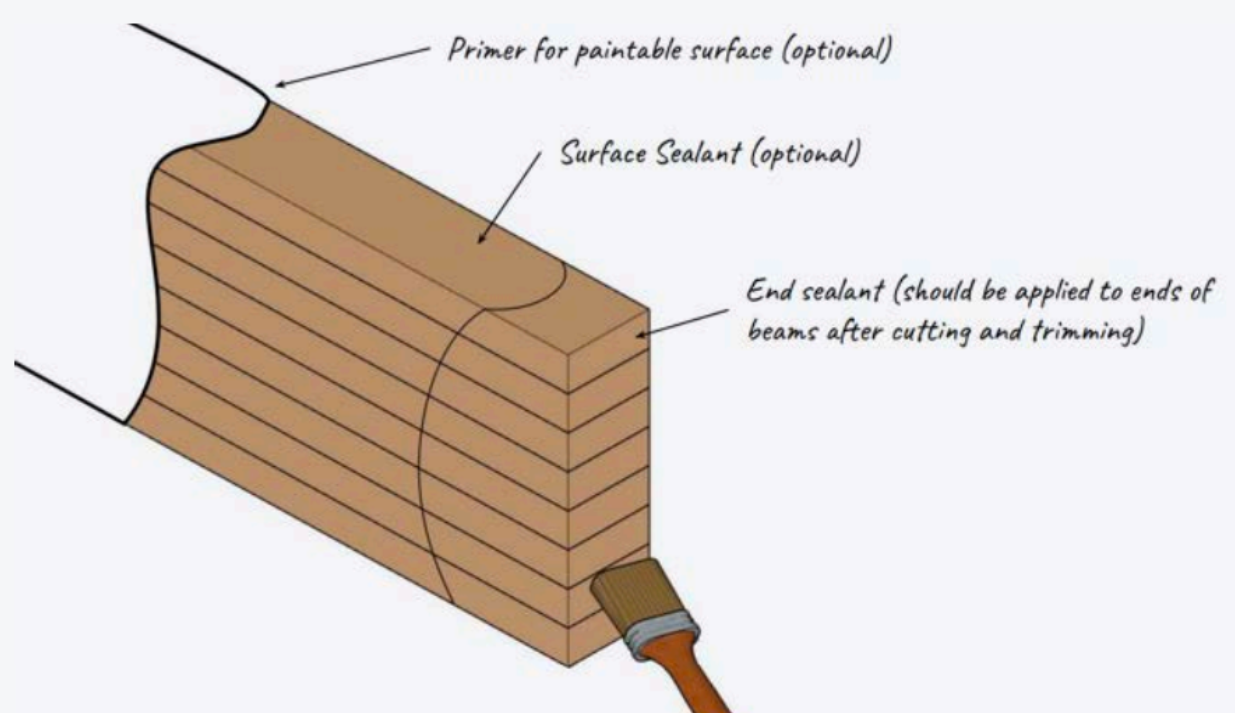

On-site modification of prefabricated timber should be minimised and carefully controlled. Unplanned cutting can expose untreated zones, damage coatings, or compromise engineered bonds.

Guidelines

- Pre-plan penetrations for services (electrical, plumbing, HVAC)

- Avoid cuts across bond lines in Glulam, LVL, or CLT without engineering sign-off

- All cut ends on treated timber must be resealed with compatible preservative

- Use sharp tools to prevent chipping in coated or visual-grade products

- Pilot-drill dense hardwoods or treated pine to avoid splitting

Touch-Up & Resealing

- Use sealants or preservatives compatible with the original treatment system

- Site modifications may void warranties or product certification unless verified

Figure 6: End grain sealer applied to glue-laminated beam (WS TDG 53 p25)

See: [Site Modifications - Preservative Resealing Protocols]

See: [CLT & Glulam Service Routing and Coordination]

Assembly and Installation Tolerances

Maintaining dimensional accuracy during installation is essential for both structural performance and appearance.

Key Principles

- Tolerances should align with product supplier specifications or AS/NZS standards

- Allowance must be made for movement (e.g. seasonal shrinkage, creep) in joint and fixing design

- Architectural alignments (e.g. exposed Glulam or junctions between materials) require careful planning of datum points and reference lines

- Pre-coordinated shop drawings must be referenced on site for fastening, penetration zones, and service clashes

Avoid excessive on-site reworking to "make fit"-it introduces misalignment and moisture entry points.

See: [Installation Tolerances and Fixing Systems]

See: [Prefabrication and Sequencing in Timber Construction]

Assembly and Installation Tolerances

Maintaining dimensional accuracy during installation is essential for both structural performance and appearance.

Key Principles

- Tolerances should align with product supplier specifications or AS/NZS standards

- Allowance must be made for movement (e.g. seasonal shrinkage, creep) in joint and fixing design

- Architectural alignments (e.g. exposed Glulam or junctions between materials) require careful planning of datum points and reference lines

- Pre-coordinated shop drawings must be referenced on site for fastening, penetration zones, and service clashes

- Avoid excessive on-site reworking to "make fit"-it introduces misalignment and moisture entry points.

See: [Installation Tolerances and Fixing Systems]

See: [Prefabrication and Sequencing in Timber Construction]