In service, uncontrolled moisture can trigger dimensional instability, biological degradation, corrosion of connections, surface damage, and in extreme cases, structural failure. Effective timber design and detailing requires a comprehensive understanding of how moisture infiltrates, migrates through, and escapes timber-across every stage from specification and delivery to occupation and maintenance. Whether through:

- Direct liquid exposure (rain, flooding, condensation, or capillary action), or

- Atmospheric absorption (humidity-driven uptake through vapour exchange),

moisture affects timber in diverse and dynamic ways. These effects depend on species properties, detailing quality, construction sequencing, protection strategies, and climate. Effective moisture management is a non-negotiable element of both good design and regulatory compliance.

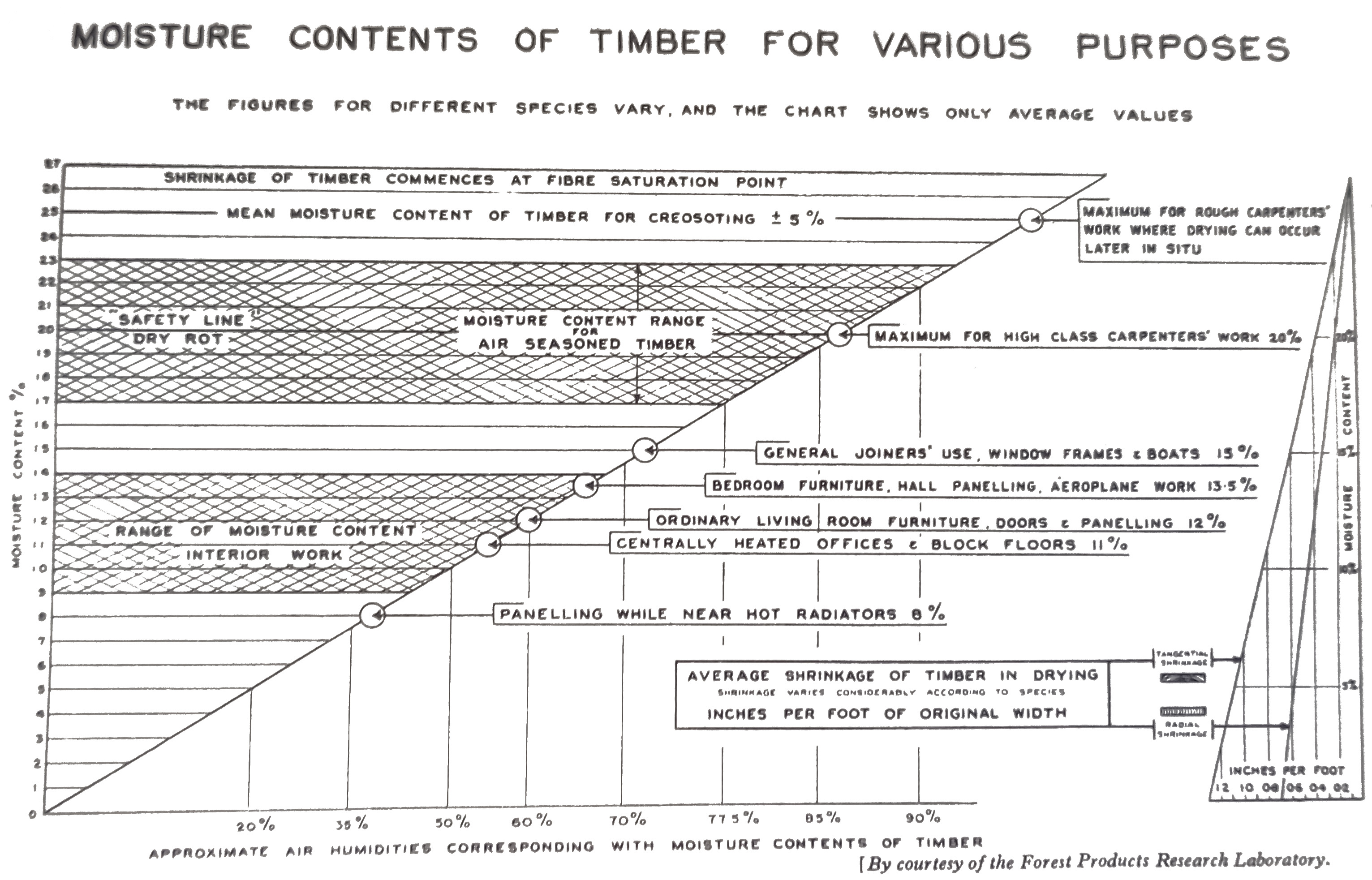

Carpenters, suppliers, builders and specifiers have been managing moisture in timber for as along as timber has been used in long-lasting applications. The chart below is published from the Timber Development Association (London, England)'s 1953 publication Red Book - Timber. This chart demonstrates the broad differences in application, and implications for geometric stability for various timbers. It should be used as a general guide illustrating the factors at play:

Figure 1: Moisture Contents of Timber for Various Purposes - Timber Development Association, England, 1953

1.1 Key Considerations for Moisture in Timber Construction

Equilibrium Moisture Content (EMC)

Timber adjusts its internal moisture content to match ambient humidity and temperature. This state is known as Equilibrium Moisture Content (EMC). Understanding EMC is fundamental to predicting timber movement, shrinkage, and swelling in various building environments.

Related: [Timber Movement & EMC Guide]

Related: [Climate-Based Moisture Considerations for Timber Across Australia[

Multiple Sources of Moisture

Moisture exposure is not always visible. Obvious wetting (rain, condensation) is often well managed, but invisible risks such as vapour diffusion, humidity fluctuations, and construction-phase wetting present a greater long-term threat. These hidden mechanisms are particularly relevant in airtight or highly insulated buildings.

Related: [Moisture Management During Construction]

Moisture-Driven Degradation

At moisture contents above 20%, timber becomes susceptible to fungal decay, mould growth, and fastener corrosion. Below that threshold, excessive drying can still induce shrinkage-related stresses, leading to splitting, checking, and loss of fixity.

Figure 2-mould Growth on Timber Frames and Sheet Flooring (Source: Meyer Timber)

Moisture Control through Design

Best-practice moisture control starts with good design: protective detailing, ventilation, drainage planning, and appropriate material selection. This is essential to avoid interstitial condensation, end-grain absorption, and long-term serviceability issues.

1.2 Regulatory Considerations

The National Construction Code (NCC) and associated standards (AS 1720.1, AS 1684, AS 2796.1, AS 4785.1, AS 1604, and CTIQ guidance in Queensland) define acceptable moisture content, protection methods, and construction protocols. Compliance with these standards is essential to ensure structural integrity, long-term durability, and resistance to environmental moisture exposure.

1.2.1 Moisture Content Requirements

Structural Sawn Timber:

- Seasoned timber should be within 10-15% MC (±3% of EMC) at time of installation

- Unseasoned timber may exceed 25% MC, but risks dimensional instability

Product-Specific Guidelines (AS 2796.1 / AS 4785.1):

- Decking: 10-18%

- Cladding / Fascia / Bargeboards: 9-14%

- Lining and Strip Flooring: 10-18%

- Dressed Boards, Joinery, Mouldings: 9-14%

1.2.2 Site Moisture Protection

Effective site moisture management is crucial to prevent structural damage and health issues such as mould growth.

- Subfloor Ventilation:

- NCC Housing Provisions (Part 6.2) mandate ventilation to prevent moisture accumulation in enclosed subfloor spaces.

- Damp-Proof Courses & Vapour Barriers:

- Required under slabs and behind wet areas (NCC Part 3.3 and 3.4) to prevent rising damp and termite-related moisture risks.

1.2.3 Weatherproofing

Proper weatherproofing ensures the longevity and durability of timber cladding by protecting it from environmental elements.

- Installation Requirements:

- Timber wall cladding must be installed in accordance with Part 7.5 of the ABCB Housing Provisions, which specifies methods to ensure weatherproofing and durability.

- Flashing and Sealing:

- Appropriate flashing must be installed at all openings, including windows and doors, to prevent water ingress.

- Sealants compatible with timber movement should be used to accommodate expansion and contraction.

- Drainage and Ventilation:

- A cavity system behind the cladding is recommended to facilitate drainage and ventilation, reducing the risk of moisture build-up.

- Protective Coatings:

- Applying suitable protective coatings, such as paints or sealants, is advised to enhance the timber's resistance to weathering.

1.2.4 Decay & Rot Prevention

Preventing decay and rot is essential for maintaining the structural integrity of timber components.

- Durability Classifications:

- Timber should be selected based on its durability classification appropriate for the intended use and exposure conditions.

- Treatment Requirements:

- Where necessary, timber should be treated in accordance with AS 1684.2:2021 to enhance resistance to decay and insect attack.

- Design Considerations:

- Design elements should promote water runoff and prevent water pooling on timber surfaces.

- Maintenance:

- Regular inspection and maintenance are crucial to identify and address potential issues before they lead to significant damage.

1.2.5 Insect Management

Protecting timber from insect attack, particularly termites, is vital for the longevity of timber structures.

- Termite Risk Management:

- The NCC 2022 requires termite management systems in areas where termites are prevalent.

- Acceptable methods include chemical treatments, physical barriers, and resistant materials, as specified in Part 3.4 of the ABCB Housing Provisions.

- Design Features:

- Incorporating design features that allow for easy inspection of termite barriers and timber elements is recommended.

- Compliance with Standards:

- Termite management systems should comply with AS 3660.1, which outlines requirements for new building work.

- Regular Inspections:

- Ongoing inspections are essential to detect and address any signs of termite activity promptly

Key Takeaways

- Moisture is a design-critical factor, influencing service life and compliance.

- Moisture exposure occurs through both visible and invisible mechanisms.

- Australian Standards and NCC provide clear moisture-related thresholds.

- Regulatory obligations span framing moisture limits, site detailing, decay prevention, and termite management.

Moisture plays a defining role in timber’s behaviour, influencing its dimensional stability, durability, and structural integrity. Timber’s hygroscopic nature (unlike non-porous materials) means it is constantly exchanging moisture with its environment-gaining and releasing water based on ambient temperature and humidity. This interaction is essential to understand, as it governs how timber performs in different climates and applications.

This section explains the foundational science behind moisture behaviour in timber, covering:

- Moisture Content (MC)

- Equilibrium Moisture Content (EMC)

- Common moisture sources and exposure pathways

- Vapour diffusion and interstitial condensation

- Moisture measurement techniques

Together, these principles underpin all moisture-related decisions in design, specification, and construction.

2.1 Moisture Content (MC)

Before being manufactured into timber, the wood in trees withstands decades of exposure to weather without significant deterioration or change. It is when we place it in service that we experience difficulties. The living tree requires large quantities of water to enable soil nutrients to be conveyed to the leaves for photosynthesis. Trees contain 40% to 200% water compared to their dry mass. This high moisture content in the wood protects the trees from fungal attack.

Moisture content (MC) is a measure of how much water is contained in a piece of wood relative to the wood itself. Moisture content is expressed as a percentage and calculated by dividing the weight of water in the wood by the weight of that wood with no water, i.e. oven-dried.

When freshly harvested, the wood is saturated with water, mainly contained in the space in the wood cells and some combined within the cell’s walls (see Figure 2a). However, wood is a hygroscopic material, which means it can release or absorb moisture to reach a moisture content at equilibrium with its surrounding environment. The freshly harvested wood wants to dry out, and the water contained within the cell space is lost first until there is no more. This is termed the ‘fibre saturation point’. Any further moisture within the wood is combined with the cell walls. Fibre Saturation Point varies for each timber species, generally around 26% to 28% being the average. Radiant pine is a little higher at 29%.

Figure 3: Types of water in timber (WS TDG 46 p112) (WS TDG 53 p5)

2.2 Equilibrium Moisture Content (EMC)

Timber does not retain a fixed moisture level; over time, it adjusts its moisture content to match its surroundings. This natural process is governed by relative humidity (RH) and temperature, leading to what is known as equilibrium moisture content (EMC) where it neither gains nor loses moisture.

- When humidity is high, timber absorbs moisture, potentially causing swelling.

- When humidity drops, timber releases moisture, leading to shrinkage.

The EMC of timber varies across different geographic locations, seasons, and building environments (interior or exterior). For example:

- In coastal regions, EMC can range from 13-16%

- In dry inland areas, EMC might be 8-12%

- In climate-controlled interiors, 8-10% is typical

Moisture Content of Wood in Sheltered Outdoor Locations

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | Ave |

Adelaide | 8 | 7 | 10 | 11 | 12 | 13 | 14 | 13 | 12 | 12 | 10 | 9 | 10.9 |

Brisbane | 14 | 15 | 15 | 14 | 13 | 14 | 13 | 13 | 12 | 13 | 13 | 13 | 13.5 |

Canberra | 11 | 11 | 13 | 13 | 16 | 17 | 16 | 15 | 15 | 13 | 12 | 12 | 13.7 |

Hobart | 12 | 12 | 14 | 15 | 15 | 15 | 15 | 16 | 16 | 16 | 13 | 14 | 14.4 |

Melbourne | 10 | 12 | 14 | 14 | 16 | 17 | 18 | 17 | 16 | 15 | 14 | 14 | 14.8 |

Perth | 11 | 10 | 11 | 12 | 14 | 15 | 16 | 16 | 15 | 13 | 12 | 13 | 13.1 |

Sydney | 13 | 14 | 14 | 14 | 13 | 16 | 14 | 14 | 14 | 13 | 13 | 14 | 13.8 |

Chart 1: Moisture Content Predictions for Eight Seasoned Timbers under Sheltered Outdoor Conditions in Australia and New Guinea Source: CSIRO, 1966 [17]

The EMC of seasoned timber is in indoor environments is targeted at 12%, covering most major urban centres of Australia, though it may be higher or lower depending on seasonal conditions:

- High humidity or exposure to wet conditions leads to timber absorbing moisture and increasing in MC.

- Low humidity or warm conditions cause timber to dry, reducing MC.

Where movement is constrained, this fluctuation in moisture content can lead to internal stresses, joint separation, and cracking. EMC must also be considered when installing flooring, cladding, and linings to avoid post-installation movement or distortion.

Figure 4 - EMC of Wood at Varying Relative Humidity Levels Source: Wikipedia

EMC and Timber Performance

Maintaining timber at an appropriate MC is crucial for preventing:

- Dimensional instability (excessive shrinkage or swelling)

- Internal stresses and warping, checking, and splitting

- Misaligned joints and fixings

- Fungal decay (if moisture content remains above 20%)

2.3 Sources of Moisture in Timber

Moisture content (MC) is a measure of how much water is contained in a piece of wood relative to the wood itself. Moisture content is expressed as a percentage and calculated by dividing the weight of water in the wood by the weight of that wood with no water, i.e. oven-dried. For a discussion on the cellular behaviour of timber, see the article The Science of Timber Shrinkage & Expansion: What Designers Must Know.

Additional moisture enters timber in several ways, with different risks depending on the exposure scenario. Broadly, moisture sources fall into two categories:

Direct Liquid Exposure (Bulk Water Ingress)

- Rain, flooding, capillary action, condensation, and leaks contribute to rapid moisture absorption, particularly in exposed or unfinished timber structures.

- In construction, wetting events during framing can result in long drying times, leading to fungal risks if not managed properly.

Atmospheric Absorption (Humidity-Driven Moisture Uptake)

- Ongoing exchange with ambient air.

- Influenced by HVAC systems, insulation layers, and internal vapour loads.

- Moisture in the form of water vapour can migrate through air gaps, wall cavities, or vapour-permeable materials. This is especially problematic in sealed cavities or poorly ventilated spaces.

- High-humidity interiors (e.g. pools, laundries, kitchens, bathrooms) pose sustained risks for both untreated and engineered timber products.

- Vapour will condense into liquid water if it reaches a surface that’s cooler than the dew point temperature. This is known as surface or interstitial condensation.

Moisture accumulation may not always be visible. In modern, well-insulated, airtight buildings, vapour trapped behind membranes or linings can create hidden risk areas, especially in colder climates or air-conditioned spaces.

2.4 Vapour Diffusion and Condensation Risk

Water vapour diffusion refers to moisture movement through vapour-permeable materials, such as building membranes, timber products, or insulation. Diffusion is driven by vapour pressure differences-often from warm interior air toward the cool exterior in winter conditions.

However, most moisture movement actually occurs with airflow, not diffusion. Vapour-laden air entering cavities or behind linings can deposit moisture when it meets a cold surface, such as:

- the back of a cladding board,

- a membrane on the cold side of insulation,

- or even the interior face of a mass timber panel.

Moisture accumulation within the first 10 mm of a timber or insulation layer is particularly important to monitor, as it’s the most vulnerable zone for mould formation

This interstitial condensation is a leading cause of hidden mould and decay in modern buildings-particularly in Zones 6, 7 and 8, where condensation control is now mandated under NCC 2022.

Design implications:

- Always allow drying in at least one direction

- Avoid double vapour barriers

- Use breathable membranes and ventilated cavities

2.5 Measuring Moisture Content in Timber

To assess moisture risk, timber’s moisture content (MC) must be measured accurately. Various techniques exist, each suited to different applications. For a deep dive into when and how to select and use moisture meters, please refer to the article Guide to Measuring Moisture in Timber: Choosing the Right Method

1. Resistance Moisture Meters (Pin-Type)

- Uses electrical resistance between two pins inserted into the timber.

- Provides fast readings, but can be affected by species type and temperature.

- Most effective for measuring moisture in framing and solid timber members.

- Affected by species and temperature.

Figure 5: Resistance Moisture Meter Source: TDA

2. Capacitance Moisture Meters (Pinless)

- Uses an electric field to detect moisture without penetrating the timber surface.

- Useful for non-invasive, broad scanning

- May be less accurate for deeper readings.

3. Oven-Dry Method (Laboratory Testing)

- Laboratory-standard method

- Involves weighing timber before and after complete drying in an oven.

- Most precise method, but time-consuming and impractical for field use.

Related: [Guide to Measuring Moisture in Timber: Choosing the Right Method]

Moisture Thresholds for Timber Use (CTIQ + AS Standards)

- Framing (dry use): ≤ 18%

- Appearance-grade linings: 12-14%

- Flooring and cladding: 10-18% (species dependent)

Tip: For mass timber or engineered products, avoid readings over 16% before enclosure.

Key Takeaways

- EMC is central to understanding timber behaviour-it reflects climatic and indoor conditions

- Moisture enters timber both visibly (liquid) and invisibly (vapour)-both must be managed

- Vapour condensation is a hidden but serious threat in sealed assemblies

- Choosing the right moisture meter is essential to effective risk management

Moisture interacts with timber in ways that affect not only its appearance, but its structural integrity, durability, and service life. The consequences of poor moisture control can be immediate or delayed-some issues appear within days, while others take years to manifest.

This section outlines how moisture causes:

- Dimensional movement (shrinkage and swelling)

- Surface damage (staining, tannin bleeding)

- Biological degradation (fungal decay, mould, algae)

- Structural compromise (cracking, delamination, corrosion)

3.1 Swelling, Shrinkage & Dimensional Stability

Timber is a hygroscopic material, meaning it continuously absorbs and releases moisture in response to its surroundings. These fluctuations result in changes to its dimensions, which can be problematic if not accounted for in design and construction. These changes are generally not uniform and vary by species, grain direction, and exposure conditions. The extent of movement is largely determined by a range of moisture change that occurs due to environmental changes, which varies with relative humidity and temperature.

- When moisture content increases, timber swells, leading to tight-fitting joints, buckling, or compression failures.

- When moisture content decreases, timber shrinks, potentially causing cracks, gaps, and distortion in structural elements.

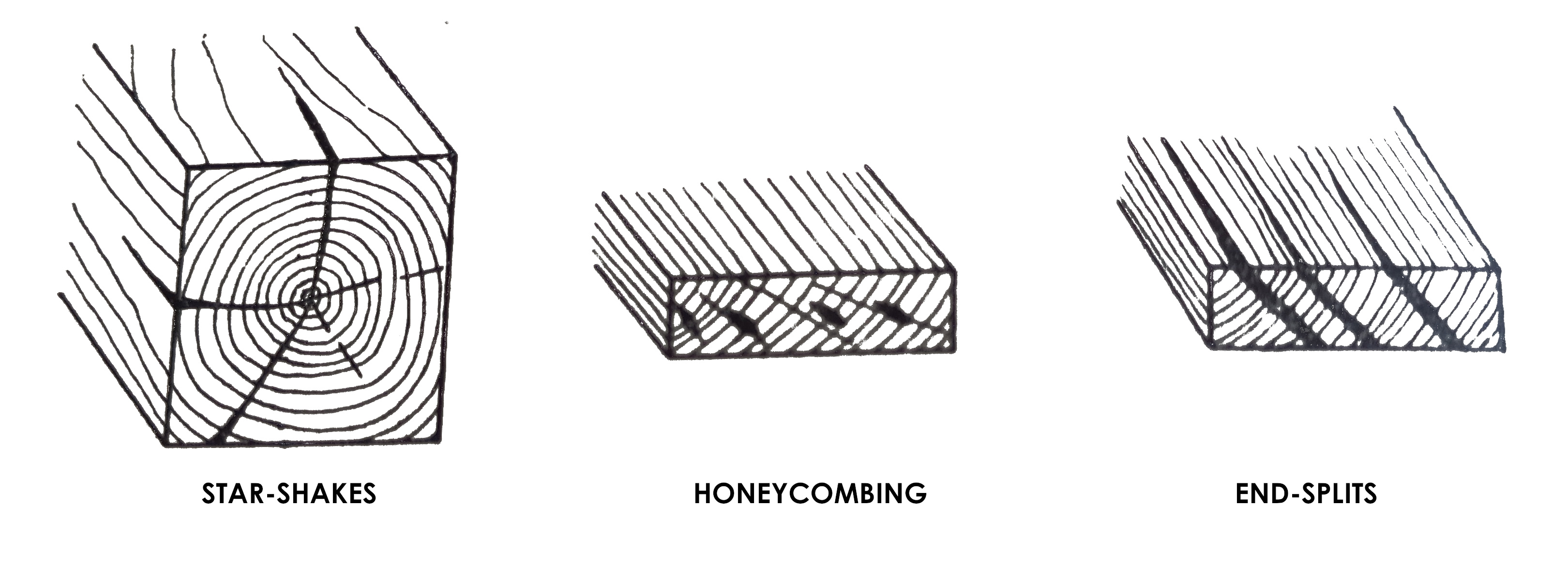

Figure 6: Common types of gaps due to uneven shrinkage - TDA

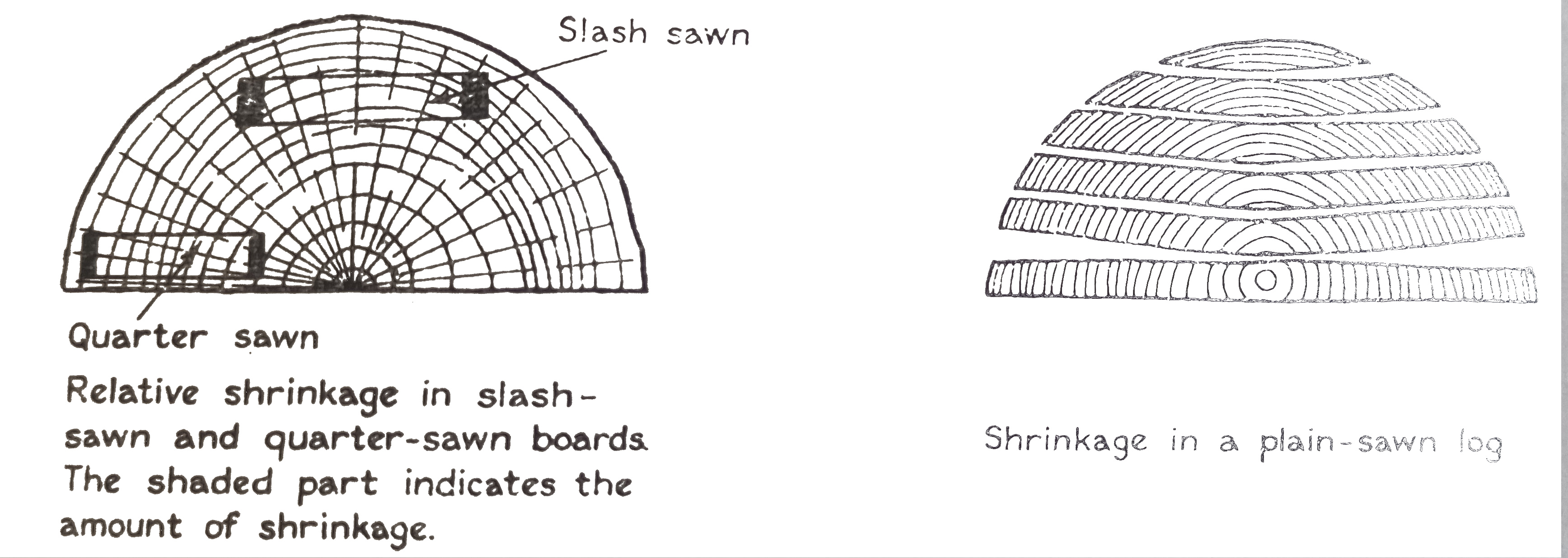

Swelling and shrinkage occur at different rates in different directions:

- Tangential movement (along the growth rings) is typically twice as large as radial movement.

- Radial movement (across the rings) is more restrained but still significant.

- Longitudinal movement (along the grain) is minimal.

Figure 7: Shrinkage Across a Log - TDA

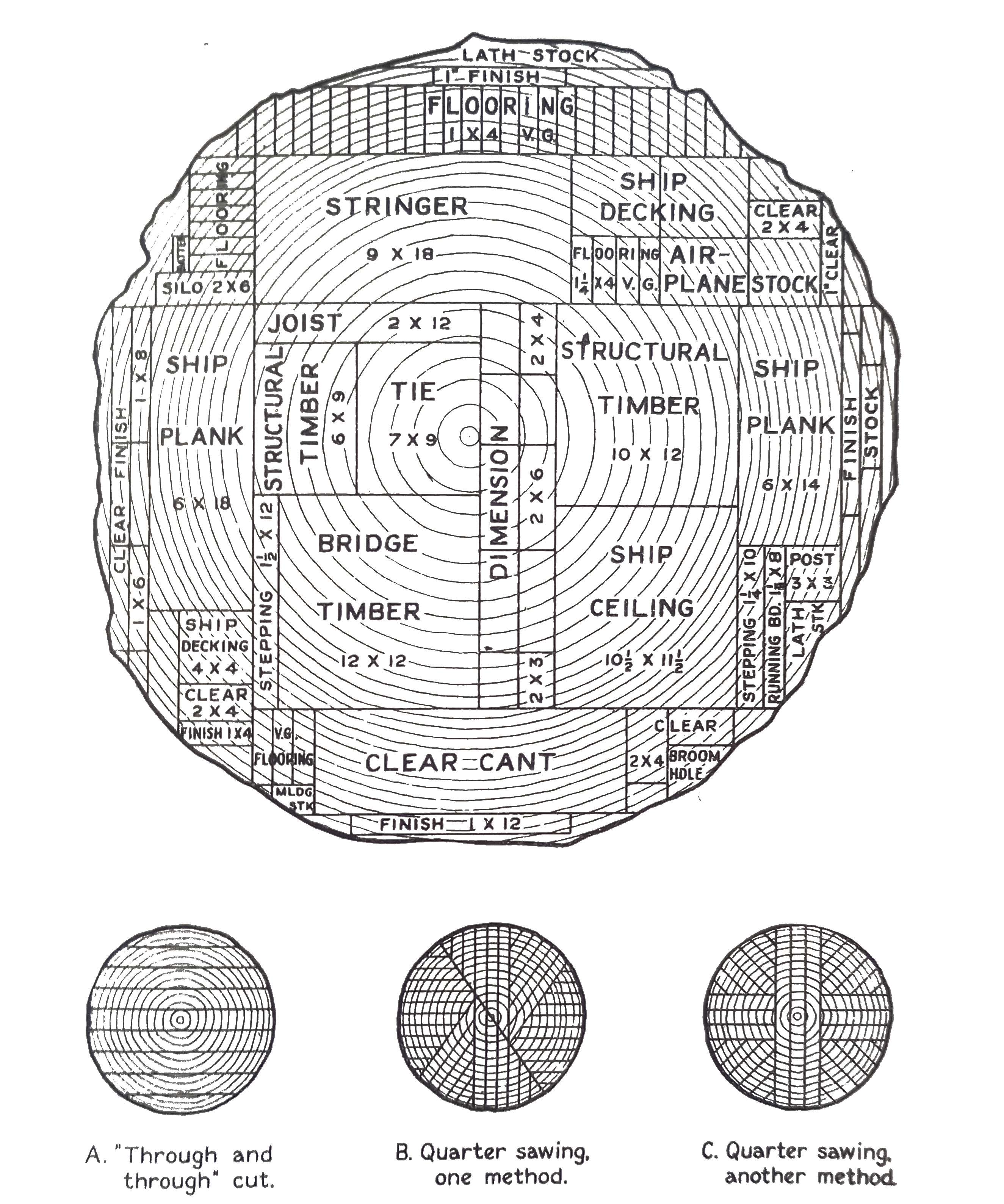

Figure 8: Methods of processing a log and historic applications accounting for shrinkage behaviours - TDA

Unit Tangential Movement Definition and Explanation

Unit tangential movement refers to the amount of dimensional change that timber undergoes along the tangential plane of its growth rings due to variations in moisture content. This movement is expressed as a percentage per 1% change in moisture content. It is the most significant type of shrinkage and swelling in timber, typically occurring twice as much as radial movement and several times more than longitudinal movement. It is affected by:

- Species Variation: Different species exhibit different tangential movements, with denser hardwoods generally experiencing greater changes.

- Grain Orientation: Quarter-sawn timber has less tangential movement than back-sawn timber due to the orientation of the growth rings.

- Moisture Influence: Movement occurs primarily between the fibre saturation point (≈25-30% moisture content) and the equilibrium moisture content (~12%).

- Design Implications: Engineers and builders must account for this movement in cladding, flooring, and joinery applications to prevent warping, splitting, or joint failure.

Figure 9: Unit Tangential Movement per Cent for Common Structural Timbers Source: AS 1684

Design Implications:

- Allow for movement in flooring, lining, and joint detailing

- Limit differential movement in hybrid systems (e.g. timber-steel junctions)

- Pre-condition materials to site EMC before installation

3.2 Staining & Surface Issues

Moisture can cause various forms of staining, each with different underlying causes. While some stains are cosmetic, others indicate deeper structural or chemical issues.

Water Staining

Water dissolves tannins and other extractives within timber, which then migrate to the surface, leaving discoloured patches. This is common in timber panels and structural beams that have been exposed to weather.

Figure 10 - Water Staining on CLT Panel - TDA

Iron Staining

Iron reacts with moisture and tannins in certain hardwoods, creating blue-black stains around steel fasteners, nails, or sawdust. This is particularly common in species such as Blackbutt.

Figure 11: Iron staining on wood from metal nails. Source: TDA

Tannin Bleeding

Some timbers, particularly those used in decking and external cladding, release tannins when exposed to prolonged humidity. This results in brown streaks on coatings and surrounding materials.

Figure 12: Tannin staining to support structure.

3.3 Fungal Decay, Mould and Algae

If timber remains above 20% moisture content for extended periods, it becomes vulnerable to fungal attack. Decay fungi consume the wood’s cell structure, leading to loss of strength and eventual failure.

Types of Decay Fungi

- Brown rot - Destroys cellulose. Causes timber to shrink, darken, and become brittle. Affected timber fractures into cube-shaped fragments.

- White rot - Breaks down both cellulose and lignin, leaving timber soft and fibrous.

- Soft rot - Affects timber in consistently damp conditions, such as poorly ventilated subfloors.

Moisture and warmth are required for fungal activity. Cold climates are not immune.

Figure 13: Timber rot at different stages

Mould Growth

Mould does not degrade timber structurally but is a reliable indicator of excess moisture, poor ventilation, or insulation-related cold bridging. Often found in interstitial spaces, where vapour condenses but cannot dry.

- Common at junctions, inside walls, around services, and beneath poorly vented roofs

Associated with health issues in buildings, including asthma and respiratory conditions

Figure 14: Mould on timber beam - TDA

Algae

Algae are nucleus-bearing organisms that lack a plant’s true roots, stems and leaves. Algae is different from mould, a fungus that eats nutrients to survive, while algae are more plant-like, containing chlorophyll (see Figure 10). Algae is differentiated from mould as algae are associated with surface water. Algae may grow on all surfaces, as it does not feed off the substrate it is on. Its presence does not often affect timber substrate. It primarily affects the visual appearance and slipperiness of timber surfaces.

Figure 15: Algae on a timber fence - TDA

3.4 Structural Issues: Cracking, Checking & Fastener Corrosion

Repeated wetting and drying cycles create internal stresses, leading to both surface and structural failures.

- Cracking & checking - Uneven drying causes tension within the timber, leading to surface cracks, splits, or deep checks that can weaken structural members.

- Fastener corrosion - Moisture exposure accelerates the rusting of metal fixings, particularly in treated timber, where certain preservatives react with metal fasteners.

Figure 16: Cracks due to drying stresses in large timber members - TDA

Figure 17: Examples of Corrosion in Moisture-Exposed Timber Connectors (WS TDG 5 p68/69)

Key Takeaways

- Timber is a dynamic material-moisture-induced movement must be designed for

- Visual clues (staining, mould) often precede more serious structural issues

- Moisture above 20% can activate decay fungi-ventilation and drying are critical

- High-tannin species and reactive fasteners should be detailed to avoid corrosion and staining

- Drying pathways and drainage are essential in all timber interfaces

Moisture management in timber design is not about eliminating exposure entirely-it’s about minimising prolonged wetting, promoting drying, and selecting appropriate materials, finishes, and construction methods.

Effective detailing and planning mitigate decay, movement, corrosion, and staining while satisfying both performance and regulatory requirements. They also reduce long-term maintenance and risk exposure-critical for insurance, documentation, and compliance.

This section outlines design strategies across:

- Timber selection and treatment

- Protective detailing

- On-site moisture management

- Coatings and sealants

4.1 Timber Selection & Treatment

Selecting the right timber product for a specific environment is central to successful moisture management. Timber must be chosen based on its natural durability or, where needed, supplemented with appropriate preservative treatments. Both approaches are governed by classification systems that guide designers and builders in matching timber to service conditions.

Two distinct rating systems are used in Australia. Note that they operate in opposite ‘directions’:

- Natural Durability Classes range from Class 1 (most durable) to Class 4 (least durable),

- Reflects natural resistance to decay and termite attack

- Preservative Treatment Hazard Classes (H levels) range from H1 (lowest hazard, dry internal use) to H6 (highest hazard, marine exposure).

- Higher number = greater treatment level required

It’s important not to confuse these systems. For example, a Durability Class 1 timber (like Ironbark) may require no treatment in most settings, whereas a Durability Class 4 timber (like Radiata Pine) may require treatment to H3 or higher depending on its application.

Note: Australian durability classes have no correlation to international durability classes.

Documentation and Compliance:

Proper documentation of timber selection-including species, durability class, treatment type and intended application-is now often required for both building approvals and insurance risk assessments. Products used in construction should also include a Product Technical Statement (PTS) or equivalent documentation outlining:

- Intended application

- Relevant NCC or AS compliance

- Maintenance requirements

- Certification or testing references

CTIQ Alignment:

Queensland guides emphasise clarity in durability/treatment combinations. For example, Radiata Pine (Durability Class 4) must be treated to H3 or higher for external above-ground use.

4.2 Construction Detailing for Moisture Management

Effective detailing is essential to managing moisture in timber structures. It ensures that water is shed efficiently, vapour can escape, and condensation is prevented in areas where it might otherwise accumulate. Poor detailing can allow moisture to become trapped in wall or roof assemblies, increasing the risk of mould, decay, and structural degradation.

Construction detailing must also comply with the National Construction Code (NCC), which includes specific requirements for condensation management through vapour-permeable membranes, cavity drainage, and ventilation.

Protecting Timber from Direct Exposure

- Provide eaves, overhangs, or canopies to reduce direct rainfall onto timber cladding and exposed elements.

- Flashings and drips should be designed to redirect water away from joints, sills, and bottom edges of panels.

- Horizontal elements, such as exposed beams, handrails, or parapets, must include a fall to drain and incorporate waterproofing membranes or durable coatings.

- Where joints between timber members are exposed, they should be detailed with taped joints, joint sealants, or gasket systems to prevent water ingress.

Figure 18: Architectural detailing - shielding (WS TDG 05 p44)

Figure 19: Isolation of timber from moisture traps (WS TDG 05 p44)

Figure 20: Provide sloping cuts or capping to posts (WS TDG 05 p44)

Figure 21: Capping protects top and end grain of projected beam (WS TDG 05 p44)

Figure 22: Drainage Holes (WS TDG 05 p44)

Ventilation and Vapour Management

- Cavity ventilation should be provided behind cladding to allow drying of moisture that penetrates past the outer layer.

- Use vapour-permeable membranes in external wall build-ups to allow trapped moisture to escape without allowing water ingress.

- Avoid concealed, unventilated cavities around junctions (e.g. balcony connections, roof interfaces, or internal shafts), which can trap moisture and lead to long-term degradation.

- Where vapour barriers are used internally (e.g. in air-conditioned buildings), ensure they are placed on the warm side of the insulation to avoid interstitial condensation.

Drainage and Water Management

- Drainage systems should be integrated into floor and roof detailing. This includes:

- Floor sumps

- Temporary roof drainage (during construction)

- Grading of floor plates to drain towards internal or temporary drains

Figure 23: Tape used to seal joints and end grain (WS TDG 52 p25 XLam Australia)

- Site grading and landscaping must direct surface water away from the building perimeter.

Sealing and Detailing of End Grains and Interfaces

- End grain sealing is critical for exposed vertical elements like columns and beams, as end grain can absorb moisture up to 10x faster than the face grain.

- Insurers consider end grain exposure a critical detailing oversight that can lead to fungal or mould risks.

Figure 24: End grain to Glulam columns (MassLAM)

- All penetrations and interfaces (e.g. between timber and concrete or steel) should include flashing or compressible sealants to accommodate movement and prevent water tracking.

Quality Assurance and Insurance Considerations

- Insurers expect that moisture detailing is reflected in:

- shop drawings,

- installation guides, and

- QA inspections.

- Items such as sealant tapes, cavity closers, and joint reinforcements should be explicitly called out.

- Where moisture-sensitive detailing is implemented, it should be supported by:

- Documentation of sequencing

- On-site inspections during weatherproofing installation

- Photographic records and test reports, especially around temporary protection during construction

- CTIQ and insurers recommend photographic records of:

- Weatherproofing installation

- Temporary protection systems

- High-risk junctions

4.3 Moisture Management During Construction

The construction phase presents the greatest risk for moisture exposure in timber buildings. Timber elements are frequently exposed before enclosure, and weather events-particularly prolonged rainfall or high humidity-can introduce moisture that may be trapped within assemblies. This can lead to swelling, discolouration, fungal growth, or structural degradation. Further, insurance providers regard construction-phase moisture protection as a critical part of risk assessment.

Pre-Construction Planning

- Develop a moisture management plan before site work begins. This plan should:

- Define target moisture contents for all timber elements

- Identify inspection and approval points

- Outline materials and methods to protect timber during storage and installation

- Account for site-specific weather conditions and likely periods of rain, humidity, or condensation.

- Plan construction sequencing to prioritise the installation of weathertight elements as early as possible:

- Roof and drainage

- Waterproofing membranes

- Vapour barriers

Delivery and Site Handling

- Schedule just-in-time delivery to reduce storage time and avoid accumulation of timber on-site.

- Clearly define procedures for delivery inspection, including:

- Moisture content

- Packaging damage

- Labelling and orientation

- Ensure unloading zones are level, drained, and accessible, and use lifting gear that does not damage timber surfaces.

Figure 25: Correct support of slings and mass timber

Storage Conditions On-Site

- Store timber off the ground using bearers or dunnage, with spacing to allow airflow.

- Use breathable waterproof covers (avoid plastic tarps without vents, choose woven membranes) to allow drying while still protecting from rain.

- Prevent water pooling under straps or props to prevent staining

- Label and track materials to minimise handling and avoid leaving items uncovered while searching for components.

Figure 26: Site storage of mass timber panels (XLam Australia)

Figure 27: Stored timber elements. (Image credit: TDA)

Temporary Protection During Construction

- Install temporary weather protection systems over partially enclosed buildings, including:

- Shrink wrap scaffold sheeting

- Scaffolding with suspended tarps

- Temporary roofing systems

- Seal exposed surfaces with protective coatings or membranes, especially if they will form finished surfaces later.

- Ensure joints are taped and sealed to prevent water from entering panel interfaces.

Figure 28: Taped joint to CLT floor (TDA)

Install stormwater diversion measures such as temporary gutters, downpipes, and floor sumps during construction.

Figure 29: Temporary downpipes. (Image: Rothoblaas)

Monitoring and Moisture Checking

- Moisture content should be measured:

- At delivery

- After major weather events

- Before enclosure (e.g. before linings are installed)

- Use resistance or capacitance moisture meters, taking readings at representative depths and avoiding adhesive lines in engineered products.

- For sensitive applications, consider continuous monitoring systems using sensors installed within timber elements.

Figure 30: Temporary point moisture measuring installed in mass timber (TDA)

Rapid Response Protocols

- Develop procedures for responding to unplanned wetting:

- Clear responsibilities for drying, removal of wet materials, and reassessment

- Bring dehumidifiers, fans, and pumps available for drying enclosed spaces.

- Record all events, moisture-level readings, and actions taken for quality assurance and insurance documentation.

4.4 Protective Coatings & Sealants

Timber exposed to weather or high-humidity environments requires an additional layer of protection to minimise moisture ingress. Protective coatings and sealants serve to reduce absorption, enhance surface durability, and maintain the aesthetic appearance of exposed elements. The presence and documentation of appropriate protective treatments are viewed as part of a project's broader quality assurance strategy.

These systems are most effective when integrated into the design and construction sequencing, particularly for elements that remain exposed or form part of the finished interior.

Types of Protective Coatings

- Penetrating Oils and Water Repellents

Provide surface-level moisture resistance while allowing vapour to escape, reducing the risk of trapping moisture beneath the surface. Best suited for exterior cladding, exposed beams, and externally visible timber elements where a breathable, natural finish is preferred. Commonly used on decking, pergolas, and architectural timber where maintaining the wood’s natural aesthetic is important. - Film-Forming Coatings (Paints and Polyurethanes)

Create a physical barrier to water ingress. These can be effective but are more susceptible to cracking or peeling if the timber moves. They are best suited to stable, protected surfaces with limited exposure to direct UV or weather. - End-Grain Sealers

Crucial for elements such as columns, beams, and decking ends, where end grain absorption is a known source of moisture intrusion. Sealing end grain is now considered essential by both moisture experts and insurers.

Sealant and Membrane Detailing

- Sealant Tapes and Liquid-Applied Membranes

Used around panel joints, corners, and mechanical fixings. These prevent moisture from entering panel gaps and help maintain the performance of mass timber products. - Temporary Sealers for Construction-Phase Exposure

Used to reduce water staining or damage prior to enclosure. These may be peeled off or over-coated once the building envelope is complete

Application Guidelines

- Apply coatings and sealants before installation where possible. Pre-coating in the factory or off-site ensures more uniform protection and avoids gaps created during cutting or handling

- Reapply coatings on cut surfaces, particularly at exposed ends, bolt holes, and connection zones.

- For architectural timber, coat all faces-including hidden or interfacial zones-to avoid localised swelling or patchy weathering.

- Ensure coatings are compatible with adhesives, vapour barriers, and subsequent finishes.

- Where coatings serve both an aesthetic and protective role, define the maintenance cycle in the project documentation (e.g. 2-5 year recoat schedule).

4.5 Insurance and Quality Assurance Considerations

Protective treatments should be recorded as part of the project’s moisture management documentation. This includes:

- Specification of product types, intended exposure class, and compatibility with timber type

- Schedule of application (e.g. at factory, pre-installation, post-installation)

- Records of areas treated, with photographic evidence if required by insurers

- Maintenance schedule for periodic inspection and re-application

Key Takeaways from This Section

- Timber treatment and selection must suit exposure conditions, with appropriate H-class ratings and supporting documentation.

- Moisture-resilient detailing includes sloped surfaces, ventilation cavities, and vapour-permeable membranes.

- During construction, protect timber using just-in-time delivery, temporary drainage, and breathable coverings.

- Seal all end grain and exposed joints to minimise absorption and staining.

- Apply protective coatings before installation and reapply as needed, especially for exposed or decorative elements.

- Maintain clear records of moisture protection measures for quality assurance and insurance purposes.

Moisture management in timber buildings is not a one-time design consideration but an ongoing responsibility that spans the entire building lifecycle-from delivery and installation to post-occupation use. This section outlines specific practices and challenges associated with different timber construction systems, including timber framing, mass timber, and flood-prone applications. Particular emphasis is given to air movement, vapour control, and drainage pathways, as these are the primary tools for reducing the risk of condensation.

Each type of construction presents unique moisture challenges. Timber-framed structures rely on weather-resistant barriers and ventilation, while mass timber buildings must prevent moisture absorption within thick timber elements. Additionally, buildings in flood-prone areas or coastal environments require special considerations to mitigate long-term moisture damage. Across all systems, a successful approach includes:

- Thoughtful sequencing

- Passive drying and drainage pathways

- Vapour control and breathable layers

- Long-term inspection and maintenance protocols

5.1 Timber-Framed Construction

Timber-framed systems rely on lightweight, enclosed assemblies and are particularly vulnerable to interstitial condensation and airborne moisture accumulation. Airtightness and insulation in modern homes reduce drying potential, making detailing critical.

Condensation Control Strategies

- Cavity Drainage

- Ensure a ventilated drainage cavity behind cladding to allow drying and prevent capillary water transfer

- Membrane Placement

- Use vapour-permeable membranes on the cold side of insulation, especially in cooler climates.

- Subfloor ventilation

- Where raised floors are used, subfloor spaces should include cross-ventilation openings to reduce humidity accumulation.

- Ensure clearance from ground moisture and install damp-proof courses where required.

- Roof space ventilation

- In climate zones 6, 7, and 8, the NCC requires ventilated roof spaces to reduce condensation risks

- Ensure insulation placement does not obstruct airflow and that ceiling spaces remain free from trapped moisture.

Long-Term Moisture Monitoring

- Check roof drainage systems annually to prevent leaks that may introduce moisture into framing cavities.

- Inspect for signs of hidden condensation issues, such as water staining on internal linings, which may indicate vapour buildup behind membranes.

- Ensure exhaust fans in bathrooms, kitchens, and laundries discharge to the exterior, not into enclosed roof or wall cavities.

5.2 Mass Timber Construction (CLT, LVL, Glulam)

Mass timber buildings have unique moisture challenges, primarily due to their thicker cross-sections, slower drying rates, and potential for condensation forming on cold timber surfaces. While mass timber is dimensionally stable, moisture intrusion during construction or post-occupancy can lead to long-term structural and aesthetic issues.

Designing for Condensation Resistance

- Maintain timber temperatures above dew point

- In insulated mass timber walls, place insulation on the exterior to prevent the timber from reaching condensation temperatures

- Where insulation is inside the mass timber, ensure vapour-permeable linings allow drying to the interior.

- Continuous vapour control layers

- Ensure vapour-permeable membranes and sealants at panel joints, openings, and interfaces with other materials.

- Where additional insulation is applied, avoid interior vapour barriers, which can trap moisture between layers.

- Avoid thermal bridging risks

- Junctions between timber walls and slabs, balconies, or external elements should be detailed with drainage slopes and moisture breaks to prevent cold bridging effects.

CLT edges and panel-to-panel connections are critical moisture entry points-detail and tape accordingly.

Post-Construction Moisture Monitoring

- Consider embedded sensors to track long-term moisture content in critical areas, especially in high-risk floor or wall zones.

- Ensure exposed structural timber elements are sealed or coated appropriately to limit water absorption while allowing vapour release

- Regularly inspect balconies, terrace interfaces, and façade penetrations for early signs of water ingress.

5.3 Flood & Water Damage Considerations

Buildings in flood-prone areas require additional moisture management strategies to ensure resilience. Timber framing and engineered wood products (e.g. plywood, LVL) react differently to prolonged water exposure, and their suitability must be assessed based on expected flood levels and drying conditions. For further information, see the article: Details and Procedures on Flood Damage

Assessing Flood-Damaged Timber

- Solid Timber

- Often salvageable if dried slowly and inspected

- LVL / Plywood

- May delaminate or swell; replacement usually recommended

- Flooring / stairs

- May cup or distort; recovery depends on drying conditions

CTIQ guidelines recommend:

- Inspecting all timber for fungal growth or distortion

- Slow, controlled drying to prevent checking or case-hardening

- Reassessment of structural performance post-exposure

Designing for Flood Resistance

- Use naturally durable species or H3-H5 treated timber for structural elements.

- Elevate key structural components above expected flood levels where possible.

- Ensure post-flood drying occurs under controlled conditions to avoid excessive cracking.

Figure 32: Effects of Prolonged Moisture on Plywood & LVL

Key Takeaways

- Framed buildings: Use breathable wraps, ventilated cavities, and subfloor airflow to prevent condensation

- Mass timber: Insulate externally, maintain dry joints, and embed sensors where risk is high

- Flood-prone sites: Use treated/durable timbers, allow access for drying, and apply detailing for water resistance

- Inspection and maintenance plans are essential for long-term durability

Moisture protection doesn't end at installation. While design and construction set the foundation, it’s ongoing inspection, handling, and maintenance that ultimately determine timber's long-term performance.

This section presents a practical toolkit for:

- Site storage and handling

- Moisture barrier installation

- Long-term maintenance and inspection

- Tools for early detection

These practices are increasingly expected by certifiers, insurers, and quality assurance frameworks across Australia.

6.1 Storage & Handling of Timber

See Section 4.3

6.2 Moisture Barrier Systems

Moisture barriers prevent ingress and support drying by controlling the movement of water and vapour through building assemblies.

Types of Moisture Barriers

Barrier Type | Function | Common Use Cases |

Breathable vapour membranes | Allow drying; stop water ingress | External walls, roofs |

Waterproof coatings | Seal exposed timber surfaces | Decking, exposed beams |

Capillary breaks | Prevent wicking from adjacent materials | Sill plates, beam-to-masonry joints |

Application Guidelines

- Apply wraps and membranes before cladding or linings

- Overlap and tape membrane joints per manufacturer instructions

- Use sloped detailing and flashing to direct water outward

- Always seal end grain and penetrations after cutting

Moisture trapped beneath film-forming coatings or membranes is a common failure point.

6.3 Regular Inspection & Maintenance

Even well-designed timber structures require ongoing inspection to detect and address emerging moisture issues before they cause significant damage.

Key Inspection Points

- Roof & Gutter Systems - Ensure proper drainage and check for leaks.

- External Cladding & Joinery - Inspect coatings for wear and reapply as needed.

- Subfloor Ventilation - Verify airflow is unobstructed and free from excessive humidity.

- Fasteners & Metal Fixings - Check for corrosion, particularly in coastal environments or treated timber.

Maintenance Schedule

- Annually: Inspect coatings, check drainage systems, and assess ventilation performance.

- Every 2-5 years (or more frequently, refer to manufacturers recommendations): Reapply protective coatings where needed, especially on decking and cladding.

- After extreme weather events: Check for water ingress, swelling, or signs of fungal growth.

CTIQ and insurers may require documented inspections and maintenance actions for liability purposes.

6.4 Early Detection of Moisture Issues

Using moisture meters and other diagnostic tools helps detect hidden moisture before it leads to structural deterioration. Refer to article: Guide to Measuring Moisture in Timber: Choosing the Right Method

Recommended Tools

- Resistance and capacitance moisture meters

- Used during construction for regular checks, especially before enclosure.

- Embedded moisture sensors

- Installed in mass timber elements for long-term internal monitoring.

- Moisture indicator stickers

- Used during transit or storage to indicate exposure events.

- Environmental monitoring stations

- Track humidity and temperature in stored or enclosed areas.

- Thermal Imaging Cameras

- Detects moisture build-up behind walls and concealed cavities.

Image: Moisture monitoring of mass timber floor (TDA)

Key Takeaways

- Store timber off the ground and covered with breathable membranes

- Apply and detail moisture barriers correctly-seal all cuts and penetrations

- Schedule regular inspections of all moisture protection systems

- Use appropriate tools to detect hidden moisture before it causes damage

- Maintain full records of inspections, coatings, and remedial actions