Overview

Clause C2D11 [2019: C1.10] of the Building Code of Australia Volume One (BCA) requires any linings, materials or assemblies in a Class 2 to 9 building used for flooring, floor covering and wall and ceiling lining materials to comply with Specification 7 - Clause S7C3, S7C4 and S7C6 [2019: Spec. C1.10: 3, 4 and 6]. All other materials (i.e. whatever holds up the floor covering or lining) are required to comply with Specification 7 Clause S7C7 [2019: Spec C1.10: 7].

The same product may have a different requirement depending on its use. For example, if plywood flooring is used on joists and bearers, the plywood is required to comply with Specification 7 Clause S7C3 [2019: Spec C1.10: 3] when the plywood is the topmost layer, i.e., exposed plywood flooring. When it has a carpet, decorative timber or tiles etc over it, then the plywood is required to comply with Specification 7 Clause S7C7 [2019: Spec C1.10: 7] with the topmost layer of carpet or other floor covering required to comply with Specification 7 Clause S7C3.

For materials used as floor linings or floor coverings in lift cars, they must comply with Specification 7 Clause S7C6(a) [2019: Spec C1.10: 6]

Similarly for walls, a lining such as timber linings or panels are required to comply with Specification 7 Clause S7C4 [2019: Spec C1.10: 4]. The studs that are used to support the linings are required to comply with Specification 7 Clause S7C7 [2019: Spec C1.10: 7].

For materials used as wall and ceiling linings in lift cars, they must comply with Specification 7 Clause S7C6(b) [2019: Spec C1.10: 6].

Fire Hazard Properties Specification 7 Clause S7C7 Other Materials [2019: Spec C1.10: 7]

This Specification sets out the requirements in relation to fire hazard properties of materials and assemblies used in Class 2 to 9 buildings other than floor, wall and ceiling covering and linings. Specification 7 Clause S7C7 [2019: Spec C1.10: 7] places limits on the Spread-of-Flame Index and Smoke-Developed Index for various types of buildings and locations within these buildings. The Spread-of-Flame Index and Smoke-Developed Index for some commonly available timber species can be found in Table 1.

The Spread-of-Flame Index and Smoke-Developed Index for some commonly available timber species in Table 1 have been sourced from the National Construction Code Volume One, Deemed-to-Satisfy referenced document AS1684.2-2021 Residential timber-framed construction, Appendix G – Table G1 Timber Species and Properties.

| Common Name | Spread-of-Flame Index (0-10) | Smoke-Developed Index (0-10) |

|---|---|---|

| Ash, Alpine | 8 | 3 |

| Ash, Mountain | 8 | 3 |

| Ash, Silvertop | 6 | 3 |

| Ash, Victorian | 8 | 3 |

| Baltic, Red | 9 | 3 |

| Baltic, White | 9 | 4 |

| Blackbean | 8 | 3 |

| Blackbutt | 7 | 3 |

| Blackbutt (plywood) | 7 | 3 |

| Blackbutt, New England | 7 | 3 |

| Blackwood | 9 | 3 |

| Bloodwood, Red | 8 | 3 |

| Box, Brush | 7 | 3 |

| Box, Grey | 4 | 3 |

| Brownbarrel | 8 | 3 |

| Brushbox | 7 | 3 |

| Cedar, Red, Australian | 8 | 3 |

| Cedar, Red, Western | 10 | 4 |

| Cypress | 8 | 3 |

| Fir, Douglas (Oregon) | 9 | 3 |

| Fir, Hem | 9 | 3 |

| Gum, Blue, Sydney | 6 | 3 |

| Gum, Grey, Mountain | 0 | 3 |

| Gum, Red, River | 3 | 3 |

| Gum, Rose | 7 | 3 |

| Gum, Rose (plywood) | 8 | 3 |

| Gum, Shining | 8 | 4 |

| Gum, Spotted | 3 | 3 |

| Gum, Spotted (plywood) | 7 | 3 |

| Hemlock, Western | 9 | 3 |

| Ironbark, Grey | 0 | 3 |

| Ironbark, Red | 5 | 3 |

| Jarrah | 6 | 3 |

| Kapur | 7 | 3 |

| Karri | 7 | 3 |

| Lauan | 9 | 4 |

| Mahogany, Philippine | 9 | 4 |

| Mahogany, Red | 5 | 3 |

| Mahogany, White | 0 | 3 |

| Maple, Pacific | 9 | 4 |

| Meranti | 9 | 4 |

| Merbau (Kwila) | 0 | 5 |

| Messmate | 5 | 3 |

| Oak, Tasmanian | 8 | 3 |

| Oak, Tulip | 6 | 2 |

| Pine, Canada | 7 | 3 |

| Pine, Cypress | 8 | 3 |

| Pine, Hoop | 7 | 2 |

| Pine, Hoop (plywood) | 9 | 3 |

| Pine, Klinki | 9 | 3 |

| Pine, Radiata | 8 | 3 |

| Pine, Slash | 8 | 3 |

| Pine, Slash (plywood) | 8 | 3 |

| Ramin | 7 | 3 |

| Redwood, Californian | 9 | 4 |

| Seraya | 9 | 4 |

| Stringybark, Silvertop | 6 | 3 |

| Stringybark, Yellow | 7 | 3 |

| Tallowwood | 5 | 4 |

| Teak | 9 | 5 |

| Turpentine | 6 | 3 |

| Walnut, Queensland | 7 | 3 |

| Walnut, Yellow | 7 | 1 |

Note: nominal thickness of samples tested: red baltic 21.5 mm; white baltic 44mm; plywoods 12mm; mountain grey gum 15 mm; silvertop ash, New England blackbutt, red bloodwood, grey box, brownbarrel, Sydney blue gum, river red gum, rose gum, shining gum, grey ironbark, red ironbark, karri, kwila, slash pine silvertop stringybark, yellow stringybark and turpentine 19mm.

Fire Hazard Properties Specification S7C3 Floor Linings and Coverings [2019: Spec C1.10: 3]

A floor covering is required to have Critical Radiant Flux (CRF) greater than specified values dependent on building type, location within the building and whether or not a sprinkler system is to be installed. Where the building does not have a sprinkler system it must also have a Smoke Development Rate of less than (<) 750 percent-minutes.

The lowest CRF value allowed for non-sprinkled buildings is 1.2 kW/m2 with no requirement for some sprinkled buildings. For various building types and specific locations within buildings there is an increased CRF being 2.2 or greater or 4.5 or greater. The different levels are related to whether a sprinkler system is installed and the mobility of the occupants or closeness to an exit. The highest requirement is 4.5 kW/m2 for fire isolated exits.

There are many combinations of timber floors that are available from parquet, strip flooring, plywood, floating and exposed particleboard and plywood floors. Generic data is available from the timber industry for products that are not specific to the one manufacturer; for example, tongue and groove (T&G) flooring or plywood that are from the one species. Floating floors and particleboard vary from manufacturer to manufacturer and the individual manufacturer should be consulted for this information.

The critical criteria for T&G flooring and parquet are the species and the thickness of the timber. There will be different CRF values for different thicknesses within the one species.

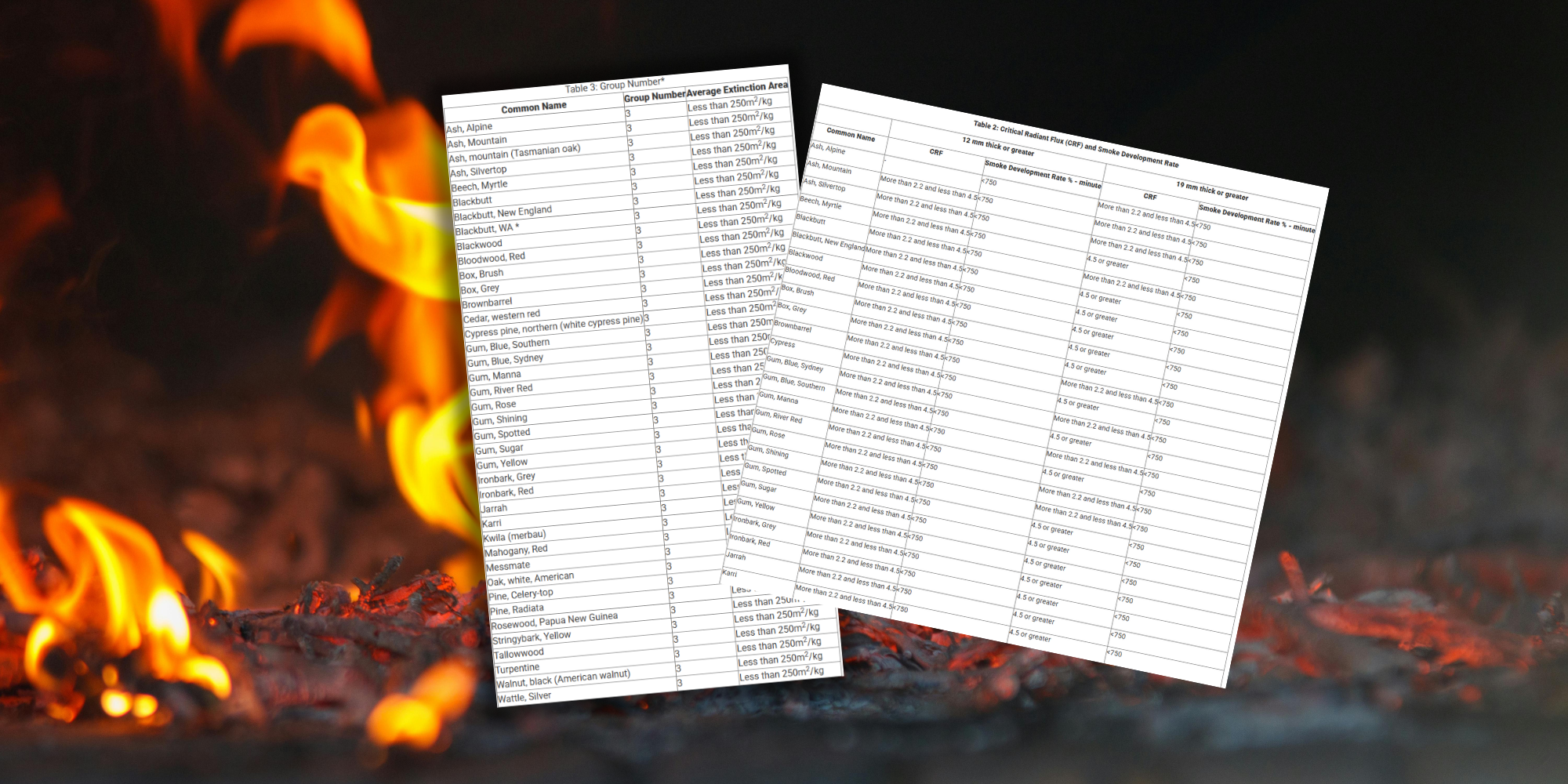

The results of testing on various timber species and their performance is provided in Table 2 which is broken into two parts; 12 mm and 19 mm thicknesses for various species. For 12 mm flooring (i.e. parquet or strip) there is a requirement that it be backed by particleboard, or placed onto a non-combustible substrate such as concrete.

A common mistake made by designers when specifying particleboard or plywood flooring under a carpet, is to require the substrate floor to have a CRF. This is not necessary when the substrate is not the topmost covering. In this instance, the Fire Hazard Properties will be required for the particleboard or plywood flooring substrate and the CRF will be required for the carpet. But when a carpet manufacturer tests carpet to determine CRF data, the carpet and substrate used e.g., plywood or particleboard, should be nominated as part of the test.

| 19 mm thick or greater | ||

Common Name | CRF | Smoke Development Rate % - minute | CRF |

| Ash, Alpine | - | <750 | More than 2.2 and less than 4.5 |

| Ash, Mountain | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Ash, Silvertop | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Beech, Myrtle | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Blackbutt | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Blackbutt, New England | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Blackwood | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Bloodwood, Red | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Box, Brush | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Box, Grey | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Brownbarrel | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Cypress | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Gum, Blue, Sydney | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Gum, Blue, Southern | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Gum, Manna | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Gum, River Red | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Gum, Rose | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Gum, Shining | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Gum, Spotted | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Gum, Sugar | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Gum, Yellow | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Ironbark, Grey | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Ironbark, Red | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Jarrah | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Karri | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Mahogany, Red | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Merbau | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Messmate | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Pine, Celery-top | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Pine, Radiata | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Stringybark, Yellow | More than 2.2 and less than 4.5 | <750 | More than 2.2 and less than 4.5 |

| Tallowwood | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Turpentine | More than 2.2 and less than 4.5 | <750 | 4.5 or greater |

| Wattle, Silver | <750 | 4.5 or greater | |

Fire Hazard Properties Specification S7C4 Wall and Ceiling Linings [2019: Spec C1.10: 4]

Wall and ceiling linings are required to meet different specified performances for different building types, location within the building and whether or not it is sprinkled. Material used for wall and ceiling linings is required to have a Group Number of 1, 2 or 3 and buildings not fitted with sprinklers are required to have a Smoke Development Rate of not more than 100, or an average extinction area less than 250m2/kg.

Generally speaking, Group 3 materials refer to timber products, Group 2 materials are predominately fire retardant timber and Group 1 materials are non-combustible or near non-combustible. All materials are required to be assessed in order to assign the appropriate Group Number. Table 3 provides a summary of group numbers for common solid timber species.

| Common Name | Group Number | Average Extinction Area |

|---|---|---|

| Ash, Alpine | 3 | Less than 250m2/kg |

| Ash, Mountain | 3 | Less than 250m2/kg |

| Ash, mountain (Tasmanian oak) | 3 | Less than 250m2/kg |

| Ash, Silvertop | 3 | Less than 250m2/kg |

| Beech, Myrtle | 3 | Less than 250m2/kg |

| Blackbutt | 3 | Less than 250m2/kg |

| Blackbutt, New England | 3 | Less than 250m2/kg |

| Blackbutt, WA * | 3 | Less than 250m2/kg |

| Blackwood | 3 | Less than 250m2/kg |

| Bloodwood, Red | 3 | Less than 250m2/kg |

| Box, Brush | 3 | Less than 250m2/kg |

| Box, Grey | 3 | Less than 250m2/kg |

| Brownbarrel | 3 | Less than 250m2/kg |

| Cedar, western red | 3 | Less than 250m2/kg |

| Cypress pine, northern (white cypress pine) | 3 | Less than 250m2/kg |

| Gum, Blue, Southern | 3 | Less than 250m2/kg |

| Gum, Blue, Sydney | 3 | Less than 250m2/kg |

| Gum, Manna | 3 | Less than 250m2/kg |

| Gum, River Red | 3 | Less than 250m2/kg |

| Gum, Rose | 3 | Less than 250m2/kg |

| Gum, Shining | 3 | Less than 250m2/kg |

| Gum, Spotted | 3 | Less than 250m2/kg |

| Gum, Sugar | 3 | Less than 250m2/kg |

| Gum, Yellow | 3 | Less than 250m2/kg |

| Ironbark, Grey | 3 | Less than 250m2/kg |

| Ironbark, Red | 3 | Less than 250m2/kg |

| Jarrah | 3 | Less than 250m2/kg |

| Karri | 3 | Less than 250m2/kg |

| Kwila (merbau) | 3 | Less than 250m2/kg |

| Mahogany, Red | 3 | Less than 250m2/kg |

| Messmate | 3 | Less than 250m2/kg |

| Oak, white, American | 3 | Less than 250m2/kg |

| Pine, Celery-top | 3 | Less than 250m2/kg |

| Pine, Radiata | 3 | Less than 250m2/kg |

| Rosewood, Papua New Guinea | 3 | Less than 250m2/kg |

| Stringybark, Yellow | 3 | Less than 250m2/kg |

| Tallowwood | 3 | Less than 250m2/kg |

| Turpentine | 3 | Less than 250m2/kg |

| Walnut, black (American walnut) | 3 | Less than 250m2/kg |

| Wattle, Silver | 3 | Less than 250m2/kg |

* Note: All data are for a timber thickness of 9 mm or greater