American red oak is the trade name for eight commercially available species of oak that are sold as both timber and veneer and used in a range of interior applications.

Red Oak, Southern Red Oak, Northern Red Oak, Swamp Red Oak, Quercus falcata, Quercus rubra.

Quercus spp.

American red oak is the trade name for eight commercially available species within the large group of oaks. The trees grow extensively across the eastern part of the USA and are more abundant than the American white oak. This means that there is a good supply of Red Oak as both sawn timber and veneer, and in a range of grades and specifications. In the US red oak is often classified according to its growing region, and sold as northern red oak (Quercus rubra) or southern red oak (Quercus falcata)*.

A highly attractive timber, the sapwood of the red oak ranges from white to light brown, with a pink to red-brown heartwood. While similar in appearance to white oak, red oak has slightly smaller rays and so has a less pronounced figure. The end grain structure of the red oak is also more porous. It is a typically straight-grained wood with a coarse texture, although both colour and texture can vary dependent on the growing region. The name, red oak, comes from colour of the leaves in autumn.

American red oak is a hard and heavy wood with moderate bending strength and stiffness. It has a high crushing strength and steam bends well. AHEC Europe recently commissioned Arup to produce a guide to the use of American Hardwoods in structural applications, including red oak (http://www.americanhardwood.org/). However this guide refers to European Design Standards and Codes and is not, at this stage, applicable to Australia.

American red oak works relatively easily, machines well, and takes nails and screws, although pre-boring is recommended. The timber performs best when it has been dried slowly, as this reduces the possibility of the wood splitting and warping. As a result of red oak's high shrinkage, it can be susceptible to movement under uneven moisture conditions. The timber can be stained and polished to an extremely attractive finish, which is one of the reasons it is becoming increasingly popular around the world.

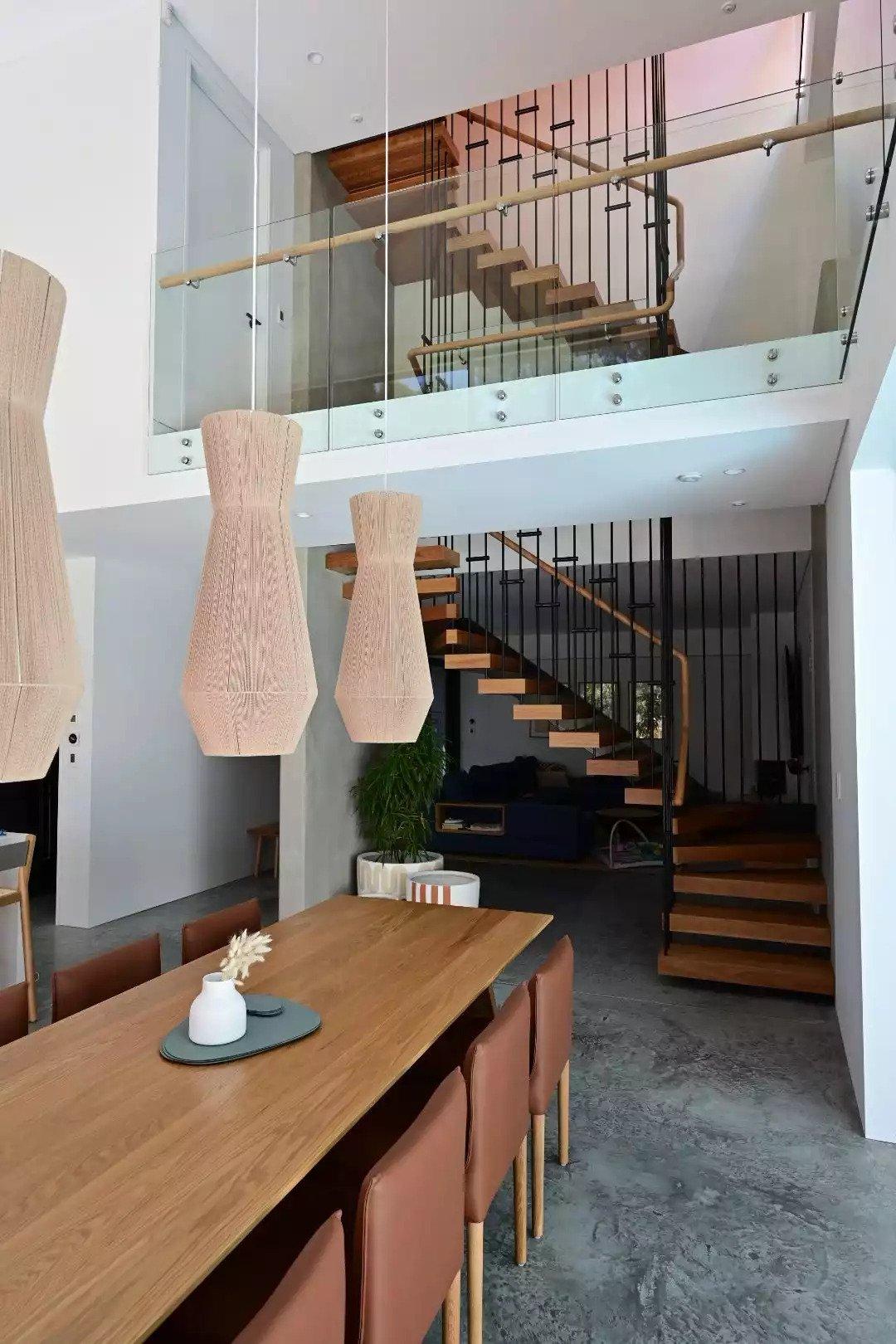

In Australia, American red oak is predominantly used in furniture, flooring, joinery, staircases, mouldings, cabinets and boat interiors. While it has structural applications it is yet to be tested for this purpose in Australia.

Red oak timber is readily available throughout Australia from specialist timber suppliers in a range of grades and specifications.

*The properties listed on WoodSolutions refer to the species known as northern red oak (Quercus rubra). Further information about the properties of southern red oak (Quercus falcata) can be found at http://www.americanhardwood.org.

Shrinkage

| Very Low | Low | Medium | High | Very High | |

|---|---|---|---|---|---|

|

|

|

|

|||

|

Tangential :

|

6.60% | ||||

|

Radial :

|

2.80% | ||||

|

Unit Movement Tangential:

|

0.37% | ||||

|

Unit Movement Radial:

|

0.16% |

Strength Group

| Very High | High | Reasonably High | Medium High | Medium | Reasonably Low | Low | Very Low | |

|---|---|---|---|---|---|---|---|---|

| Unseasoned: | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 |

|

|

||||||||

| Seasoned: | SD1 | SD2 | SD3 | SD4 | SD5 | SD6 | SD7 | SD8 |

|

|

Stress Grade

|

Structural No. 1 |

Structural No. 2 |

Structural No. 3 |

Structural No. 4 |

Structural No. 5 |

|

|---|---|---|---|---|---|

| Unseasoned: | F8 | F7 | F5 | F4 | |

| Seasoned: | F14 | F11 | F8 | F7 | F5 |

Density per Standard

| Seasoned: | 730kg/m3 |

|---|---|

| Unseasoned: | 980kg/m3 |

Joint Group

| Very High | High | Reasonably High | Medium | Low | Very Low | |

|---|---|---|---|---|---|---|

| Unseasoned: | J1 | J2 | J3 | J4 | J5 | J6 |

|

|

||||||

| Seasoned: | JD1 | JD2 | JD3 | JD4 | JD5 | JD6 |

|

|

Colour

| White, yellow, pale straw to light brown | Pink to pink brown | Light to dark red | Brown, chocolate, mottled or streaky | |

|---|---|---|---|---|

|

|

|

|||

Mechanical Properties

|

Modulus of Rupture - Unseasoned:

|

53 |

|---|---|

|

Modulus of Rupture - Seasoned:

|

87 |

|

Modulus of Elasticity - Unseasoned:

|

9 |

|

Modulus of Elasticity - Seasoned:

|

12 |

|

Maximum Crushing Strength - Unseasoned:

|

22 |

|

Maximum Crushing Strength - Seasoned:

|

44 |

|

Impact - Unseasoned:

|

|

|

Impact - Seasoned:

|

|

|

Toughness - Unseasoned:

|

|

|

Toughness - Seasoned:

|

High - 25 Nm and above |

|

Hardness - Unseasoned:

|

4.1 |

|

Hardness - Seasoned:

|

5.2 |

Durability

| Low | Moderate | Reasonably High | High | |

|---|---|---|---|---|

| (0 - 5 yrs) | (5 - 15 yrs) | (15 - 25 yrs) | (more than 25 yrs) | |

|

In-Ground:

|

|

|||

| (0 - 7 yrs) | (7 - 15 yrs) | (15 - 40 yrs) | (More than 40 yrs) | |

|

Above ground:

|

|

|||

| (0 - 20 yrs, usually < 5) | (21 - 40 yrs) | (41 - 64 yrs) | (More than 60 yrs) | |

|

Marine Borer Resistance:

|

|

Lyctid Borer Susceptibility:

|

Susceptible |

|---|---|

| Lyctid Borer Susceptibility - Other: | |

|

Termite Resistance:

|

Not Resistant |

Fire Properties

|

Bushfire Resistance:

|

Not tested |

|---|

American red oak stains and polishes to a highly attractive finish, making it a popular choice for architects and furniture makers around the world. It has a white to light brown sapwood with heartwood of pink to red-brown. It has less figure than white oak, due to the smaller rays, and is also more porous at the end grain. It has a coarse texture and its grain is usually straight.

In Australia, American red oak is most often used in interior applications, such as flooring, furniture, joinery, cabinetry and panelling. It is also used in the interior of boats. Red oak is available as a thermally modified timber suitable for exterior decking and cladding.

NSW