In a lightweight frame standard-sized timber components are spaced relatively close together (typically at 450–600 mm intervals) and nailed or plated into a rigid lattice. The main components comprise vertical studs in the walls, horizontal joists in the floors, and sloping rafters or prefabricated trusses in the roof. Each level of the building is constructed as a platform for the next, with the floor ‘platform’ established first, then wall frames and finally the roof framing above.

The result is a strong yet light skeleton of timber to which the exterior claddings and interior linings are attached. Unlike heavy post-and-beam construction, which often leaves massive wood columns exposed, lightweight framing keeps the structural elements hidden beneath cladding (e.g. brick veneer, siding) and linings (e.g. plasterboard) once the building is complete.

Figure 1: Framing skeleton of a single-storey timber house under construction, showing the platform floor, wall studs, and trussed roof framing.

Lightweight timber framing is the dominant construction system for Australian houses, accounting for 70 to 80 per cent of detached dwellings. This prevalence is due to a combination of practical advantages, such as:

- Timber has an excellent strength-to-weight ratio which means a relatively light wood frame can support substantial loads.

- Timber frames are lightweight and easy to handle, enabling faster construction with less heavy lifting equipment.

- Builders can quickly assemble walls and roof trusses on site (or install prefabricated panels and modules) with minimal delays.

- The construction process is well understood across the industry, since Australia has decades of experience building in timber.

- Designers, tradespeople and other stakeholders are deeply familiar with lightweight timber framed construction.

These factors make timber framing a fast and economical way to build, helping keep material and labour costs lower than some alternative systems.

The majority of the timber used in house frames is plantation-grown softwood, typically radiata pine that is grown locally in sustainable forests. The wood is kiln-dried and stress graded (e.g. to MGP10 or MGP12) for structural use, and is typically preservative-treated to protect against termites and decay. Most Australian framing timber is sold as treated pine, with specific ratings for different applications.

The framing system, from member sizes and spacings to nailing patterns, bracing, and tie-down details, is governed by Australian Standard AS 1684: Residential Timber-Framed Construction. Commonly referred to as the Timber Framing Code, AS 1684 provides engineers and builders with prescriptive guidelines, including span tables and connection requirements, to ensure that timber-framed houses are structurally safe and compliant with the National Construction Code (NCC).

Evolution from heavy timber to platform framing

The evolution of timber construction methods in Australia reflects a broader global shift from traditional post-and-beam framing, also known today as heavy timber construction, toward the efficient and scalable method known as platform framing.

Early Australian colonial buildings, particularly those constructed in the 1800s, relied heavily on post-and-beam construction techniques, where a building’s structure was formed from a series of large timber posts and beams, joined by mortise and tenon or pegged joints. These members were spaced widely apart and often sourced from native hardwoods like spotted gum or ironbark, hewn on-site or pit-sawn from local forests. The walls in these buildings were infilled with brick, timber planks, or lath and plaster. Frame size and complexity was limited by the difficulty of working by hand with large, heavy members. This system produced durable structures, but it was labour-intensive and not easily adaptable to emerging trends in urban growth or repetitive housing.

In the early 20th century machine-sawn timber, mass-produced nails, and industrialised joinery methods became more readily available. This enabled new framing systems to be developed, initially balloon framing, and later, platform framing. Balloon framing, which used continuous studs running from the ground to the roof It was superseded in Australia by platform framing, mainly because of its practicality and safety, particularly the reduced fire risk and ease of handling shorter timber length. In platform framing, each level of the building is framed one storey at a time; the floor of the first level is framed and sheeted, then the wall frames are erected on top, and finally the next floor or roof is built above that. This creates a strong, braced platform at each level, simplifies construction sequencing, and allows for standardised stud lengths and easier scaffolding and access during construction.

Figure 2: Diagram contrasting balloon framing (continuous studs) with platform framing (storey-by-storey platform structure).

Platform framing was particularly well-suited to Australia's post-war housing boom, where there was a need to rapidly construct large volumes of detached dwellings. Local timber mills standardised their outputs of softwood studs and joists (e.g. 90x35 mm or 90x45 mm), and Australian standards evolved to support this form of construction. The publication of AS 1684 in 1975, following the earlier Timber Engineering Handbook series, marked the formalisation of this method into national design practice.

By the late 20th century, timber framing had become the default structural system for detached housing across the country. It was also well suited to offsite prefabrication, with factories supplying pre-nailed wall frames, floor cassettes, and roof trusses, which could be delivered to site and installed rapidly. These trends continue today, with timber framing remaining a core system for both low-rise housing and, increasingly, mid-rise construction under updated NCC provisions.

This historical progression from heavy timber joinery to light, modular, platform-based construction underpins the timber framing practices used across Australia today. It forms the basis for the structural systems detailed in AS 1684, and sets the stage for innovations in sustainability, prefabrication, and code-compliant design in modern timber-framed buildings.

Why Timber Framing is So Popular

Lightweight timber framing is now the preferred structural system for the majority of homes, accounting for 70 to 80 per cent of detached dwellings in Australia.

Key to timber framing’s continued popularity is a high level of industry familiarity and a reliable, standardised supply chain that supports it. Timber framing has been taught in trade apprenticeships and practiced on sites across the country for decades. Builders, designers, building surveyors, and certifiers all have a detailed understanding of the system, reducing the risk of construction or compliance errors. This familiarity extends to material suppliers, hardware stores, and offsite prefabrication producers. This has simplified the sourcing of materials, connectors, fixings, and design tools for timber-framed structures throughout Australia. National networks of truss and frame manufacturers provide pre-nailed wall frames, floor cassettes, and engineered roof trusses tailored to standardised design codes, reducing custom detailing and on-site cutting. In regional and suburban areas alike, timber framing enjoys near-universal availability and technical support.

Timber framing is also one of the few construction systems in Australia with a fully prescriptive national standard: AS 1684 Residential Timber-Framed Construction, which provides builders and designers with detailed, code-compliant sizing, bracing, and tie-down requirements for Class 1 buildings without the need for a structural engineer. This streamlines the design and approval process for small projects, especially in low-wind or non-cyclonic regions.

Figure 3: A typical suburban Australian street under construction, showing multiple houses with exposed timber frames being assembled.

Timber framing also benefits from automation and sophisticated design and fabrication techniques. Wall frames, roof trusses, and even complete floor systems can be pre-nailed or fully assembled in offsite facilities and delivered as ready-to-install units. This reduces on-site labour time, lowers construction noise, and minimises waste. The low weight of the framing material also allows for less expensive footings and simplified crane or manual handling on site, which are especially helpful in bush blocks, sloping sites, or locations with difficult access.

Beyond construction efficiency, timber framing has strong sustainability credentials. Compared to steel or masonry, timber framing results in significantly lower greenhouse gas emissions over the lifecycle of a home.

Timber framing also provides design flexibility and ongoing adaptability. Internal walls are easily moved or modified during renovations. Openings for doors and windows can be relocated. Service integration, including electrical cabling, plumbing, and insulation can be located within wall cavities. For homeowners and renovators, this makes timber-framed homes highly responsive to changing needs and preferences over time.

Lightweight timber framing has remained Australia’s preferred construction system for many reasons. Its advantages go beyond convenience or tradition, timber frames offer tangible performance, environmental, and economic benefits.

Strength and Lightness

Timber has a high strength-to-weight ratio. A dry, seasoned softwood such as radiata pine can offer structural performance comparable to steel in many low-rise applications, yet weighs substantially less. This means timber members can carry significant loads without imposing excessive demand on footings or requiring heavy-lifting equipment on site.

In platform framing, each wall, floor, and roof component contributes to a highly efficient load-bearing chain. For example, 90x45 mm MGP10 studs at 450 mm centres can safely carry multi-storey residential loads when designed in accordance with AS 1684 span tables. When braced and tied together the frame acts as a cohesive structural shell, distributing vertical and lateral loads across all members.

Sustainability and Carbon Storage

Timber is the only major building material that is both renewable and carbon positive. Framing timber used in Australian homes is typically plantation-grown radiata pine, harvested from sustainably managed forests certified under schemes such as FSC or PEFC.

Timber stores carbon – about half of the dry weight of timber is carbon, so-called ‘biogenic carbon’ – that has been removed from the atmosphere during the growth phase, which is then stored for the life of the building. A typical timber-framed house, which incorporates approximately 12 cubic metres of lightweight timber, will store approximately 2.8 tonnes of biogenic carbon, which is equivalent to about 10 tonnes of carbon dioxide that has been sequestered from the atmosphere during the growth phase.

Durability, Termite and Fire Resistance

Modern timber frames are built to last for decades, and correct detailing ensures they perform well in Australia’s diverse climates. The use of kiln-dried, stress-graded and preservative-treated softwood gives timber protection against termite attack and fungal decay in above-ground internal applications. In areas of high termite risk, physical barriers (such as stainless-steel mesh or ant caps) and chemical-treated zones are integrated during construction, in compliance with AS 3660 and the NCC, as part of a holistic termite management system.

When covered with plasterboard or other fire-rated linings, lightweight timber frames can meet fire resistance levels (FRLs) required under the NCC for both boundary setbacks and intertenancy separations.

Cost and Speed of Construction

Framing material costs are generally lower than for steel or concrete, particularly for low-rise buildings. Prefabricated wall frames and roof trusses can be ordered from certified frame and truss plants and delivered ready to install, dramatically reducing on-site framing time. In some residential projects, a complete frame can be erected in a matter of days, bringing the project to lock-up stage quickly. This speed not only lowers construction costs but also reduces weather-related delays and allows earlier access for follow-on trades. In large-scale residential developments, timber framing supports rapid replication and repeatable detailing, key factors in efficient housing delivery.

Ease of Renovation and Adaptability

Timber’s versatility is unmatched in light framing applications. It can be cut, notched, or drilled to suit a wide range of layouts, openings, and service requirements. Wall frames can accommodate windows, doors, and service chases with simple lintels or blocking. This flexibility extends to renovation and extension, making timber-framed homes more adaptable over time than masonry or concrete buildings. Architects and designers often favour timber framing for its compatibility with both traditional detailing and modern energy-efficient design strategies, including a tendency to reduce thermal bridges.

For homeowners, timber’s adaptability means a home that can grow or change with its occupants, without requiring major structural intervention.

Lightweight timber framing follows a methodical, layered construction process. From the ground up, each component contributes to a structural shell that is strong, stable, and well suited to the needs of Australian housing. The process can vary depending on the site, layout, and project scale, but it almost always follows the platform framing method, a sequential system where each floor level forms a “platform” for the level above.

Figure 4: Multi-storey lightweight timber frame

Floor Framing (Platform Base)

Bearers, Joists, and Subfloors

In a raised timber floor system, the structure begins with a system of bearers and joists supported by vertical elements such as stumps, piers or masonry walls. Bearers span between supports and carry the joists, which are fixed perpendicular to the bearers at regular intervals—typically 450 mm centres, depending on span and floor load requirements. Joists are usually 90x45 mm MGP10 pine in standard domestic construction, but engineered options such as LVL or I-joists are increasingly used for longer spans or reduced floor depths (AS 1684.2).

Once the joists are in place, floor sheeting, commonly structural particleboard, is fixed above to create a strong, flat platform ready for wall construction. Subfloors must be detailed to allow for:

- Ventilation beneath the floor structure

- Moisture control, often via damp-proof membranes or clearances

- Termite protection, including physical barriers such as ant caps or proprietary collars, installed in line with AS 3660 requirements.

Slab-on-Ground vs Raised Floor Systems

Many Australian homes, particularly those on level suburban blocks, are built on concrete slab-on-ground foundations. In these cases, the timber wall frames are fixed directly to the slab using anchor bolts and bottom plates. This system eliminates the need for bearers and joists at ground level, resulting in faster construction and minimal site excavation. It’s also a popular choice in volume homebuilding, where repetition and flat sites make slab construction economical. However, slab-on-ground systems come with some limitations:

- They offer limited flexibility for running or modifying plumbing and services, with in-ground services poured into the slab.

- Slabs require thorough moisture management, such as vapour barriers and slab edge insulation in cooler climates.

- In reactive clay soils or areas with high termite risk, special footing designs or treatments are required to prevent long-term damage.

By contrast, raised timber floors provide a resilient, adjustable solution where ground conditions are variable. They:

- Allow for natural subfloor ventilation, which can improve durability in damp or humid regions.

- Facilitate future adaptability with plumbing, drainage or underfloor insulation.

- Reduce the risk of slab edge condensation and can be detailed to meet bushfire or flood zone requirements.

Both systems are compatible with lightweight timber framing. The choice depends on site-specific factors, local practice, and client or builder preference. AS 1684 supports detailing for both approaches, with design provisions to ensure that either system provides a level, durable and compliant base for the house frame above.

Figure 5: Side-by-side illustration comparing a slab-on-ground and a raised subfloor foundation, annotated to show their key features and components.

Wall Framing (Studs and Plates)

Typical Stud Sizes and Spacing

Wall frames form the vertical structural elements of a timber-framed building. They are built flat on the platform floor and then stood upright and fixed in place. A typical wall frame consists of a bottom plate (fixed to the floor or slab), vertical studs, noggings, and one or more top plates, which support the structure above. In residential construction, studs are typically 90x35mm or 90x45mm kiln-dried, machine-graded pine (usually MGP10 or MGP12). Heavier grades or wider members may be used in high-load scenarios such as double-storey external walls or supporting concentrated roof loads.

Studs are usually spaced at either:

- 450 mm centres (common in external, loadbearing, and bracing walls)

- 600 mm centres (permitted for internal non-loadbearing partitions or lightly loaded walls)

These spacings reflect requirements from AS 1684, which balances structural performance with ease of lining installation. Closer spacing improves stiffness and resistance to buckling, while wider spacing reduces material use. Where external cladding or internal linings require specific fixing intervals (e.g. fibre cement sheeting or large plasterboard sheets), additional studs are placed to suit manufacturer requirements.

Double top plates are often used to:

- Support point loads from trusses or upper floors

- Tie adjacent wall frames together across junctions

- Provide additional nailing surface and continuity for lintels and bracing

Figure 6: Double Top Plates - extra bending strength, and assist with assembly

Openings, Noggings, and Junctions

Wall frames are regularly interrupted by openings for doors and windows, each of which must be framed out to safely transfer loads around the void. AS 1684 provides prescriptive details and span tables for designing these openings.

Each opening typically includes:

- Lintels: horizontal structural beams above the opening (often 140x45 or larger LVL or solid timber), sized to carry roof or floor loads above

- Trimmer (or jack) studs: vertical members that support the lintel ends

- Jamb studs: full-height studs on either side of the opening, which help distribute loads into the wall

Lintel sizes are selected based on opening width, supported load, and wind classification, with tables provided in AS 1684. Longer or more heavily loaded spans may require engineered timber sections such as LVL or I-beams, especially above wide doors or feature windows.

To provide lateral stability and fixings for linings, noggings (also called blocking) are installed between studs, typically at mid-height in 2.4 m walls. In some cases, multiple rows of noggings are used, especially for taller walls or where cladding requires closer fixing support.

Wall junctions (corners, T-intersections, and returns) require special detailing to:

- Provide continuous load paths between connecting frames

- Maintain bracing integrity

- Ensure there is enough timber for internal linings and external claddings to be fixed securely

Common junction types include:

- Corner studs: paired or tripled studs to form an external corner, often with a return block

- T-junctions: where internal walls meet external walls, often framed with a blocking stud to provide fixing for linings on both walls

- Service cavities: especially in double-stud or acoustic-rated walls, created to route plumbing or wiring without compromising structure or insulation

Each of these elements must be integrated with bracing layouts, tie-down requirements, and service penetrations, which are coordinated early in the design or prefabrication process to avoid on-site modifications.

Roof Framing (Rafters or Trusses)

Timber roof framing completes the structural skeleton of a house, forming the loadbearing structure that supports roofing material, ceiling linings, and service runs. Australian houses use one of two primary framing approaches: conventional stick-built systems or prefabricated trusses. The choice depends on the project scale, roof geometry, construction speed, and builder preference.

Conventional vs Prefabricated Roofs

Conventional roof framing uses individual timber members (rafters, ridge boards, ceiling joists, and collar ties) cut and assembled on site to form the roof shape. Rafters span from the wall top plate to the ridge line, while ceiling joists tie the bottoms of the walls together and provide fixing points for internal linings. This method offers maximum design flexibility and is commonly used in architect-designed homes or projects with unique rooflines.

Stick-built roofs require skilled carpenters, careful layout, and time. They can also be more adaptable during construction, particularly when services or architectural changes are required late in the build.

Figure 7: Prefabricated truss roof during installation

Prefabricated timber roof trusses are factory-assembled structural trusses connected by pressed metal nail plates. These trusses are engineered to carry roof loads over long spans without the need for internal support walls or beams. Prefabricated trusses are now used in most volume-built residential projects across Australia due to their:

- Fast installation time

- Consistent quality and dimensional accuracy

- Capacity to accommodate complex roof geometries using engineered variants (e.g. scissor trusses, hip sets, girder trusses)

AS 1684 includes provisions for both conventional and prefabricated systems. In either case, trusses and rafters must be correctly tied down and braced to resist uplift and lateral loads (AS 1684.2 Section 9).

Hip and Gable Arrangements

Roof framing geometry typically follows one of two dominant roof shapes: gable or hip. These define how roof loads are distributed and how framing is laid out.

- A gable roof has two sloping sides that meet at a ridge, with vertical walls (gable ends) at either end of the ridge. Framing is generally simpler, with parallel rafters or trusses spanning from wall plate to ridge, and ceiling joists tying the bottoms. Gable roofs are common in suburban homes and allow easier future extensions.

- A hip roof has slopes on all four sides, with rafters or trusses meeting at hip rafters or hip trusses. The corners of the roof include jack rafters or creep members that shorten progressively toward the hips. Hip roofs offer greater wind stability and are well suited to high-wind or cyclonic regions, as they provide better load distribution across all walls (NCC Vol 2 Part 3.10.1).

Figure 8: Diagram comparing gable and hip roof geometries

Prefabricated hip roof systems are supplied as hip truss sets, including specially designed hip, jack, creeper, and girder trusses that simplify installation and reduce on-site measurement. These systems are detailed by truss manufacturers using software that ensures the load paths, overhangs, and fixing points comply with AS 1720 and AS 1684.

Regardless of configuration, roofs must incorporate:

- Batten or purlin fixing, to support roof cladding (e.g. tile battens or metal roof purlins)

- Diagonal bracing, often in the form of speed bracing or truss clips

- Tie-down connectors, such as cyclone straps or triple grips, to resist wind uplift and transfer loads to the walls and footings

Correctly designed and installed roof framing is essential for both structural safety and long-term weatherproofing performance.

Bracing and Tie-Down

While timber framing is strong and efficient under vertical loads, it must also be stabilised against horizontal forces such as wind and seismic movement, and uplift forces from wind suction. To prevent deformation or failure, the frame is reinforced using specific bracing systems and tie-down connections. These elements are not always visible once cladding and linings are applied, but they are essential to the long-term structural performance of a timber-framed building.

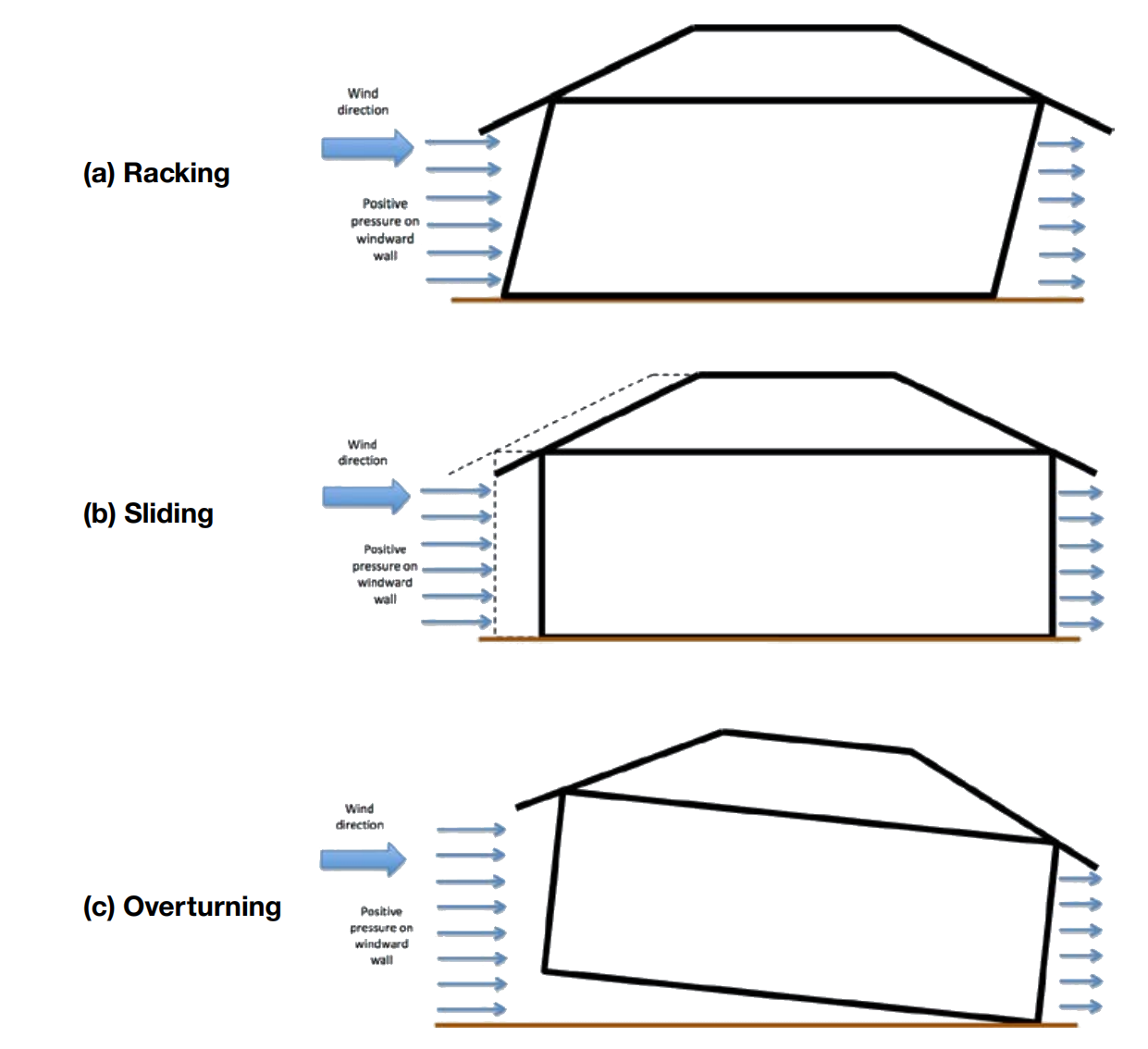

Figure 9: The three modes of lateral failure that frames and connections must be designed to resist.

Lateral Stability and Racking Resistance

Timber frames, particularly wall and floor systems, are vulnerable to racking: the sideways distortion that can occur when lateral loads (like wind or earthquake forces) act on a building. To resist this, frames must be stiffened using bracing systems that convert these horizontal loads into internal forces distributed through the frame and down to the foundations.

Bracing can take several forms, including:

- Structural sheet bracing: typically plywood, fibre cement, or oriented strand board (OSB) fixed to wall frames with specified nailing patterns

- Metal strap or rod bracing: fixed diagonally across framing to provide tension resistance

- Nominal bracing: The contribution of ‘non-structural’ fixed elements such as tightly fixed wall linings or framed return walls, which provide low levels of resistance and are only used in conjunction with other systems

The amount of bracing required depends on:

- The wind classification of the site (e.g. N1–N4 or C1–C3)

- The building’s size, height, and layout

- The spacing and location of bracing walls throughout the plan

Bracing walls must also be correctly detailed to transfer loads, hence:

- They must be connected to top and bottom plates with full-length studs

- They must be continuous to the floor structure or slab

- Bracing sheets or straps must be installed with approved fixings and edge distances

Figure 10: Types of structural arrangements to resist lateral loads

Floors and ceilings also play a role in resisting lateral loads, acting as horizontal diaphragms that distribute forces to the bracing walls. These elements must be continuous and well connected across the plan, particularly in long buildings or multi-storey projects.

Uplift Resistance and Load Paths

In addition to lateral forces, houses must resist uplift forces generated by wind acting on roofs. These forces can be significant, particularly in cyclonic regions, and can result in roofs being lifted from walls if not properly restrained. Tie-down systems are used to anchor all parts of the structure together, forming a continuous load path from the roof to the foundations.

Key components of an uplift-resistant system include:

- Truss-to-top plate connections: often using triple grips, cyclone straps, or truss clips

- Stud-to-bottom plate connections: using nails, screws or proprietary framing anchors

- Bottom plate-to-floor/slab connections: anchor bolts, threaded rods or hold-down brackets

- Multi-storey tie-downs: including continuous rods or strapping through floor levels

AS 1684 and AS 4055 provide minimum tie-down requirements based on wind category and member type. In high-wind or cyclonic zones, detailing becomes more robust, often requiring:

- Tighter fixing schedules

- Stronger brackets

- Reinforced corner conditions

All tie-down components must be:

- Corrosion-resistant for external or wet areas (e.g. hot-dip galvanised)

- Installed with the correct fastener type and pattern

- Compatible with timber treatments

Properly executed, the tie-down system ensures that dead loads, live loads, wind, and seismic loads are transferred safely and predictably through the frame and into the ground. Without this system, even a well-built timber frame is at risk during extreme weather events.

Lightweight timber framing in Australia is supported by a well-established set of codes and standards that provide both prescriptive guidance and deemed-to-satisfy compliance pathways for designers, builders, and certifiers. Chief among these is AS 1684 - Residential Timber-Framed Construction, which sets the benchmark for structural safety and consistency across timber-framed Class 1 and 10 buildings (e.g. houses, carports, garages). These standards not only ensure structural integrity, but also simplify design and approvals for most residential projects.

AS 1684: The Timber Framing Code

AS 1684 is the principal Australian Standard for designing and constructing timber-framed houses. It consists of four parts:

- Part 1: Design Criteria – Defines performance-based requirements and loading assumptions

- Part 2: Non-cyclonic Areas – Prescriptive construction practices for wind classifications N1–N4

- Part 3: Cyclonic Areas – Prescriptive construction practices for C1–C4 wind zones

- Part 4: Simplified Non-Engineering Design – For Class 1 structures in lower wind categories

These parts provide comprehensive detail on:

- Framing sizes and spacings for common timber grades

- Bracing wall requirements and distribution

- Tie-down methods and fixings

- Span limits for joists, rafters, lintels, and beams

Because AS 1684 is fully prescriptive, it allows most Class 1 residential buildings to be designed without custom structural engineering as long as the building geometry and loads fall within the standard's parameters. Importantly, AS 1684 is recognised in the National Construction Code (NCC) as a Deemed-to-Satisfy solution for structural compliance in residential timber framing. That means builders who follow the standard are deemed to meet the performance requirements of the NCC for structural adequacy.

Span Tables, Bracing Units, and Tie-Downs

At the core of AS 1684’s utility are its span tables and bracing/tie-down schedules, which allow framing members and connectors to be selected directly from tables based on:

- Load type (roof, floor, ceiling)

- Timber grade and size

- Roof pitch and cover type

- Wind classification

- Member spacing

For example, a builder can determine the appropriate size of a lintel above a window or a floor joist span based on MGP10 pine at 450 mm centres without needing to perform manual calculations. Similarly, bracing wall requirements are allocated according to wind classification and building dimensions. Tie-down is addressed using connector schedules that link each structural element together:

- Rafters/trusses to wall plates

- Wall frames to subfloor or slab

- Roof to footing via continuous or stepped load paths

Each connection type is given a minimum capacity (in kN), and the standard specifies acceptable solutions such as cyclone ties, framing anchors, triple grips, and bolted fixings. Nail size, embedment, and corrosion resistance are all covered.

These tools make AS 1684 an essential day-to-day resource for residential designers and builders.

Cyclonic vs Non-Cyclonic Provisions

AS 1684 is split into two main construction practice guides:

- Part 2: For non-cyclonic regions (wind classifications N1 to N4)

- Part 3: For cyclonic regions (C1 to C4)

The key differences between these provisions relate to the increased wind pressures expected in cyclone-prone parts of Australia, particularly northern Queensland, coastal NT, and parts of WA. These areas require:

- Closer stud and truss spacing

- Stronger bracing systems

- Enhanced tie-down detailing (e.g. continuous rods, upgraded connectors)

- More stringent fixing schedules (e.g. double nailing, specified fastener angles)

Additionally, bracing capacity per elevation increases substantially in cyclonic zones, often necessitating full-length plywood bracing walls or additional internal bracing.

Builders working in cyclonic regions must be aware of the expanded detailing obligations, particularly when using prefabricated frames. All trusses, studs, and connections must be clearly marked and installed in accordance with manufacturer documentation and Australian standards. By following the correct version of AS 1684 and the appropriate wind classification, designers and builders can ensure that a timber-framed house will perform safely and reliably under local conditions.

National Construction Code (NCC)

While AS 1684 provides detailed construction guidance, it sits beneath the National Construction Code (NCC), which sets out the performance and compliance requirements for all buildings in Australia. Timber framing, when constructed to AS 1684, is recognised by the NCC as a Deemed-to-Satisfy (DTS) solution for structural compliance, which significantly reduces the need for engineering sign-off or custom design for standard housing projects.

Deemed-to-Satisfy Pathways

In NCC Volume 2, timber framing built in accordance with AS 1684 Parts 2-4 is explicitly listed as a Deemed-to-Satisfy pathway for Class 1 and 10 buildings. This means that if a builder follows the requirements of AS 1684 they are considered to have met the NCC’s structural performance obligations without further justification.

In NCC Volume 1 for Class 2-9 buildings such as low-rise apartments, hotels, and aged care facilities, timber framing may also be used under DTS pathways where the structure remains within height, fire, and acoustic performance limits. Otherwise, Performance Solutions (e.g. fire modelling, alternative compliance documentation) may be required, notably for taller or mixed-use timber-framed buildings. The expansion of mid-rise timber allowances has further increased the scope for using timber framing in larger buildings, including up to 25 metres (typically 4-8 storeys) when combined with appropriate fire and acoustic systems.

Termite Management and Fire Requirements

Two areas where NCC compliance intersects heavily with timber framing are termite protection and fire resistance. In termite-prone zones, NCC Volume 2 Part 3.1.4 requires a termite management system to be installed. This may consist of:

- Physical barriers, such as stainless steel mesh or graded stone

- Chemical systems, like soil treatments or reticulated chemical zones

- Resistant materials, such as H2-treated timber framing above ground

For timber framing, it is common to use envelope-treated (surface treated) softwood (e.g. blue or red H2 pine) in combination with physical barriers at ground level (e.g. ant caps on stumps, slab edge systems). These measures must be detailed in the building plans and maintained throughout the building’s life.

For fire compliance, timber-framed walls must meet the stipulated Fire Resistance Level (FRL) in applications such as:

- Boundary walls, where separation from other buildings is required

- Intertenancy walls, where acoustic and fire separation is needed (e.g. in townhouses or Class 2 apartments)

Figure 11: Structural and acoustic ties used to laterally support the separating wall. TDG 01

In most cases, fire resistance is achieved not through the timber itself but by the use of fire-rated linings, such as fire-grade plasterboard, mineral board, or proprietary systems tested to relevant standards. Timber frames can support FRLs of 60/60/60 or higher when appropriately detailed.

Notching and Drilling Guidelines

To allow for electrical, plumbing, and mechanical services, timber framing often requires notching, boring, or cutting of studs, joists, and plates. While timber is highly adaptable to these modifications, there are limits to ensure structural capacity is not compromised. AS 1684.2 Table 6.1 provides clear rules for notching and drilling, including:

- Maximum hole size: Typically up to one-third of joist depth, spaced at least 3 times the hole diameter apart.

- Location limits: Holes must be in the middle third of the member depth, away from ends or concentrated stress zones.

- Notching is generally not permitted in the bottom edge of floor joists or in the compression edge of load-bearing studs.

- Edge distance for any notch or hole must meet minimums to avoid splitting.

In addition:

- Penetrations must not be located in or near bearing points, lintel seats, or bracing panels.

- Where holes exceed the standard limits, engineering advice should be sought.

These rules help prevent service penetrations from weakening the framing system and are especially critical in floor joists, where concentrated loads and vibration may lead to long-term performance issues.

Correct application of these guidelines ensures that timber’s flexibility for service integration does not come at the cost of structural integrity. Coordination between designers, electricians, plumbers, and builders during early layout stages can avoid costly on-site conflicts and reduce the need for non-compliant adjustments.

Lightweight timber framing is a construction method undertaken every day across Australia. From suburban subdivisions to remote communities, the system adapts to a wide range of conditions and project scales. Below are examples of how timber framing is put into practice, highlighting its versatility, cost-effectiveness, and growing application in more complex building types.

Typical Australian Homes

The most recognisable use of lightweight timber framing is in the freestanding detached house. In these homes, framing is typically used for:

- Raised or slab-based floor systems

- Platform-framed single or double-storey external and internal walls

- Prefabricated roof trusses or conventional rafter systems

Standard framing configurations braced with structural ply or fibre cement and tied down using proprietary connectors are employed across most house types. Claddings may include brick veneer, fibre cement, or timber weatherboards, all fixed to the frame with appropriate detailing for movement, ventilation, and drainage.

These homes often incorporate engineered timber products (e.g. LVL lintels, I-joist floor systems) to achieve longer spans, open-plan living, or wide glazing. They also demonstrate the efficiency of the framing system: once a slab or subfloor is complete, the full frame can be installed in just a few days using pre-nailed wall frames and trusses.

Figure 12: Aerial photo or street-view image of a new suburban housing development under construction, with timber frames visible across multiple sites.

Mid-Rise Timber Frame Projects

Lightweight timber framing is increasingly being used in Class 2-3 apartment buildings, hotels, boarding houses, and aged care facilities, since the NCC DTS provisions permit fire-protected timber systems in buildings up to 25 metres in height (typically 4 to 6 storeys).

In these buildings, lightweight timber framing may be used in combination with:

- Fire-rated plasterboard systems for FRL compliance

- Resilient underlays and double-stud walls for acoustic separation

- Sprinkler systems for additional protection

According to the Frame and Truss Manufacturers Association (FTMA), over a dozen mid-rise timber buildings have now been completed in Australia using light timber framing in conjunction with NCC-compliant detailing.

Prefabricated Framing in Action

One of the biggest shifts in timber framing practice is the growing use of off-site prefabrication. Wall frames, floor cassettes, and roof trusses are increasingly manufactured in certified plants and delivered ready to install.

The main benefits of prefabricated systems are that they:

- Reduce on-site labour and waste

- Improve quality through controlled manufacturing

- Minimise weather exposure during framing stages

- Reduce construction time to lock-up significantly

Builders using prefabricated frames often report reducing framing time by 50–70 per cent, with typical single-storey homes framed in two to three days. In larger developments, this approach also reduces the number of required trades on site at any one time, helping with scheduling, safety, and coordination.

Prefabrication is commonly used in:

- Volume housing

- Modular or relocatable housing

- Remote projects with limited site access

- Government-led social and Indigenous housing programs

In some projects, prefabricated systems are taken a step further, incorporating factory-installed windows, insulation, or partial linings, enabling a transition toward panelised and modular construction. Lightweight timber remains central to these systems, offering strength, workability, and compatibility with digital fabrication and CNC-based production.

Figure 13: Wall assembly in a factory setting builtoffsite

Figure 14: Prefabricated timber walls being assembled by Modscape + Modbotics automation