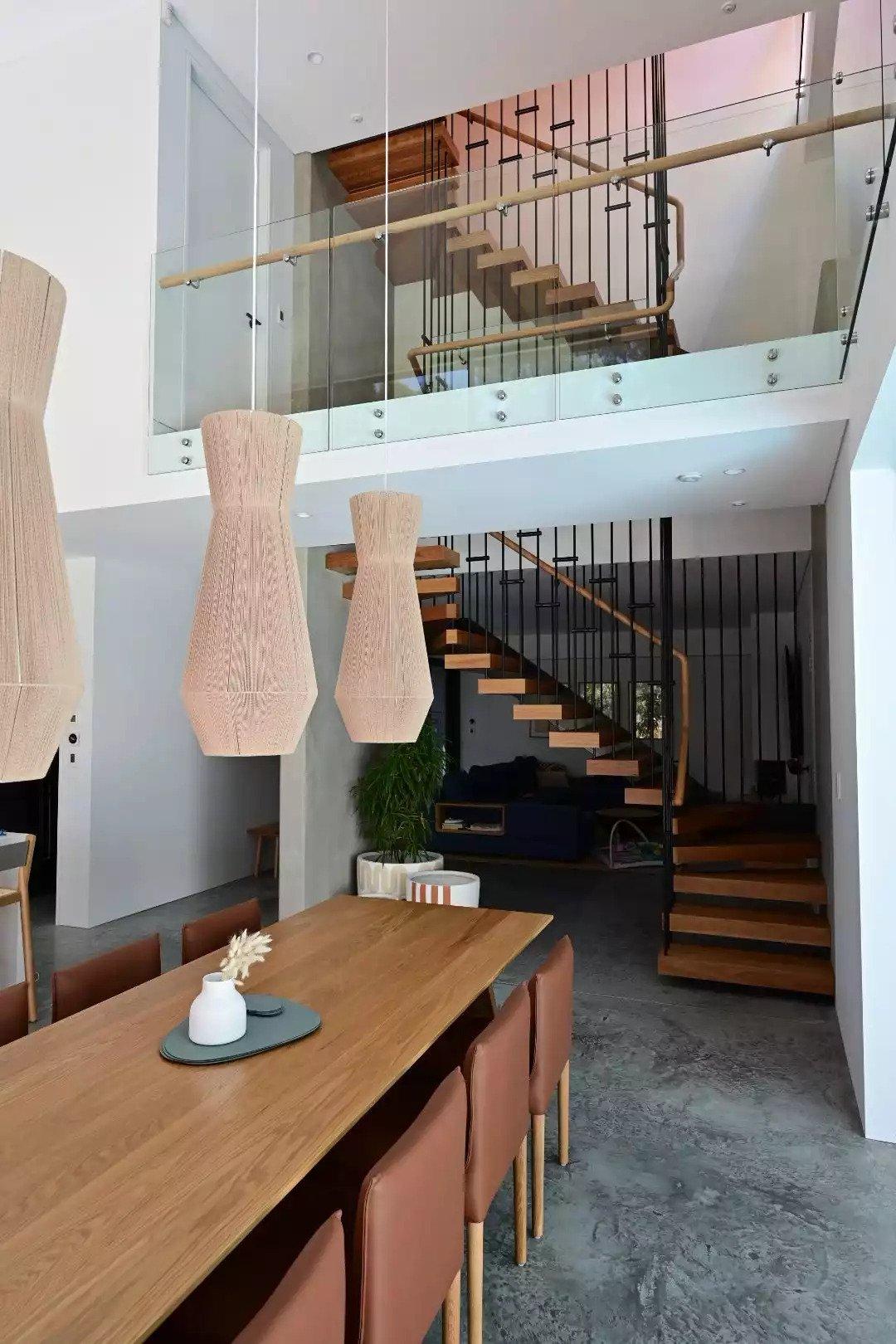

Tasmanian oak is a premium Australian hardwood timber encompassing three species that grow in the mountainous areas of Tasmania. It is a versatile timber perfect for both construction and interior applications, including flooring, panelling, architraves and skirting boards.

Mountain ash, alpine ash, gum-topped stringybark, Australian oak, whitetop stringybark, white-top, woollybutt, blue leaf, mountain white gum.

E. delegatensis, E. obliqua & E. regnans

Tasmanian oak is the name used for three almost identical species of eucalypt hardwoods that are normally marketed collectively. E. delegatensis (alpine ash) occurs at higher altitudes, while E. regnans (mountain ash) is found in wetter sites; E. obliqua (messmate) has a wide distribution, occurring in wet forests but also extending into drier areas.

Warm, dense and resilient, Tasmanian oak is the preferred hardwood for a wide range of applications. It works extremely well and produces an excellent finish. It can be used in all forms of construction and in interior applications such as panelling and flooring. It can be glue-laminated to cover long spans. Veneers, plywood and engineered products are also available. It is also a popular furniture timber, and its fibre is sought after for reconstituted board and production of high quality paper.

Tasmanian oak is light in colour, varying from straw to reddish brown with intermediate shades of cream to pink. It is recognised for its excellent staining qualities, which allow ready matching with other timbers, finishes or furnishings.

Tasmanian oak is marketed under different names depending on where it is being sold. In Victoria and NSW; it is also sometimes mistakenly referred to as Victorian ash. It should be noted however that, unlike Victorian ash, Tasmania oak also includes messmate. Consequently, Tasmanian oak has a wider and less consistent colour mix. Importantly, it should also be noted that unlike Victorian ash, Tasmanian oak is susceptible to lyctid borer.

Shrinkage

| Very Low | Low | Medium | High | Very High | |

|---|---|---|---|---|---|

|

|

|

|

|||

|

Tangential :

|

13.30% | ||||

|

Radial :

|

6.60% | ||||

|

Unit Movement Tangential:

|

0.36% | ||||

|

Unit Movement Radial:

|

0.23% |

Strength Group

| Very High | High | Reasonably High | Medium High | Medium | Reasonably Low | Low | Very Low | |

|---|---|---|---|---|---|---|---|---|

| Unseasoned: | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 |

|

|

||||||||

| Seasoned: | SD1 | SD2 | SD3 | SD4 | SD5 | SD6 | SD7 | SD8 |

|

|

Stress Grade

|

Structural No. 1 |

Structural No. 2 |

Structural No. 3 |

Structural No. 4 |

Structural No. 5 |

|

|---|---|---|---|---|---|

| Unseasoned: | F14 | F11 | F8 | F7 | F5 |

| Seasoned: | F22 | F17 | F14 | F11 | F8 |

Density per Standard

| Seasoned: | 650kg/m3 |

|---|---|

| Unseasoned: | 1050kg/m3 |

Joint Group

| Very High | High | Reasonably High | Medium | Low | Very Low | |

|---|---|---|---|---|---|---|

| Unseasoned: | J1 | J2 | J3 | J4 | J5 | J6 |

|

|

||||||

| Seasoned: | JD1 | JD2 | JD3 | JD4 | JD5 | JD6 |

|

|

Colour

| White, yellow, pale straw to light brown | Pink to pink brown | Light to dark red | Brown, chocolate, mottled or streaky | |

|---|---|---|---|---|

|

|

|

|||

Mechanical Properties

|

Modulus of Rupture - Unseasoned:

|

63 |

|---|---|

|

Modulus of Rupture - Seasoned:

|

110 |

|

Modulus of Elasticity - Unseasoned:

|

13 |

|

Modulus of Elasticity - Seasoned:

|

17 |

|

Maximum Crushing Strength - Unseasoned:

|

30 |

|

Maximum Crushing Strength - Seasoned:

|

63 |

|

Impact - Unseasoned:

|

14 |

|

Impact - Seasoned:

|

21 |

|

Toughness - Unseasoned:

|

Medium - 15 - 24 Nm |

|

Toughness - Seasoned:

|

Medium - 15 - 24 Nm |

|

Hardness - Unseasoned:

|

3.4 |

|

Hardness - Seasoned:

|

4.9 |

Durability

| Low | Moderate | Reasonably High | High | |

|---|---|---|---|---|

| (0 - 5 yrs) | (5 - 15 yrs) | (15 - 25 yrs) | (more than 25 yrs) | |

|

In-Ground:

|

|

|||

| (0 - 7 yrs) | (7 - 15 yrs) | (15 - 40 yrs) | (More than 40 yrs) | |

|

Above ground:

|

|

|||

| (0 - 20 yrs, usually < 5) | (21 - 40 yrs) | (41 - 64 yrs) | (More than 60 yrs) | |

|

Marine Borer Resistance:

|

|

|

Lyctid Borer Susceptibility:

|

|

|---|---|

| Lyctid Borer Susceptibility - Other: | Sapwood is generally susceptible. Tasmanian Oak is usually sold free of sapwood. |

|

Termite Resistance:

|

Not Resistant |

Fire Properties

|

Critical Radiance Flux - Lower:

|

>2.2 and <4.5 |

|---|---|

|

Critical Radiance Flux - Higher:

|

>2.2 and <4.5 |

|

Smoke Development Rate:

|

<750 |

| 1 - non-combustible | 2 - reasonably non-combustible | 3 - slightly combustible | 4 - combustible | |

|

Fire Properties Group Number: |

|

|

Average Specific Extinction Area:

|

>250 |

|---|---|

|

Bushfire Resistance:

|

Not tested |

Tasmanian oak is light in colour, varying from straw to reddish brown with intermediate shades of cream to pink. It is recognised for its excellent staining qualities, which allow ready matching with other timbers, finishes or furnishings.

Tasmanian oak can be used for protected structural applications, such as timber framing, but it is best suited to indoor applications and furniture due its low to moderate durability. Flooring, paneling and high-end joinery are some of its more common applications, although it is also used for agricultural implements, oars, cooperage, boxes, crates, paper pulp and in the manufacture of plywood.