Merbau is a popular hardwood derived largely from areas in South East Asia, Papua New Guinea, the Pacific islands, and northern Queensland. With its high degree of natural durability and strength it is used externally in engineering, construction and marine applications. Merbau also features in backyards as outdoor furniture, and internally in a range of joinery, flooring and other uses.

Merbau is harvested from tropical forests and, in some cases, may be sourced from forests legally converted to other land uses or where there are inadequate controls. Certified merbau is available in Australia, so it is suggested you check with your supplier. Certification and chain of custody systems, including DNA tracking, will provide assurance that the wood is from legal and/or well managed forests.

In its natural setting in North Queensland, Malaysia, Fiji, Vietnam, the Philippines, Madagascar, Papua New Guinea, Thailand, Solomon Islands, New Caledonia, Vanuatu and Samoa, the merbau species can grow up to 40 metres in height, with a 0.6 metre trunk diameter. The bushy tree, with distinctive local names, will often form a spreading canopy.

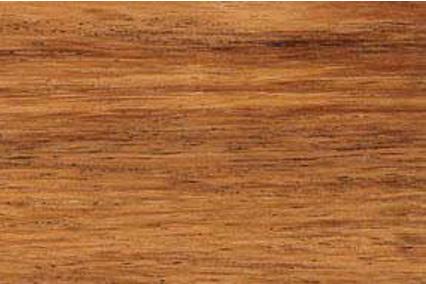

The attractive yellow-orange brown hue of freshly cut heartwood deepens or reddens with ageing. This contrasts markedly with the merbau sapwood, which is white, pale yellow or buff coloured. If left untreated, the sapwood is susceptible to lyctid borer attack. Beyond that, merbau is quite resistant to termites and seasons well with kiln or air-drying, exhibiting only a low degrade and very little shrinkage or movement. The grain of merbau can vary but it is usually interlocked or wavy, with a coarse but even texture, often prized for its attractiveness on backsawn material.

It will finish well with paint, stain, and polish although gum bleed is a possibility. Merbau is a versatile wood product. It is utilised for larger-scale projects and general construction, along with common use for outdoor settings and barbeque trolleys, and for joinery, flooring and fitting purposes. As it turns well and responds to hand tools it can be applied to more specialised work, such as cabinet making, musical instruments, boat building, carving and tool handles.