The versatility, strength and natural beauty of timber makes it the ideal material choice for external handrails and balustrades. Usually built from treated softwood and durable hardwoods these timbers can be turned to create a range of styles and designs, resulting in balusters that are unique as they are individual. Painting, staining and oil based finishes broadly cover the wide range of finishing options available and with the appropriate care and attention a timber balustrade can last a lifetime.

This guide provides general information on member sizes, connections and suitable materials to enable the construction of a long lasting, attractive and durable timber handrail or balustrade.

Criteria Level: 1

Australian Standard 1170.1 requires balustrades, railings, their members and connections provide structural support to be able to resist the following factored limit state loads - 0.9kN inward, outward and downward load at any point.

It also specifies that balustrades and handrails must be able to resist a factored horizontal or vertical load of 1.13kN/m for external balconies in domestic and other residential buildings. Infill, including balusters, should be capable of resisting 0.75kN in any direction.

Criteria Level: 2

Considering its strength, beauty and versatility it is not surprising that timber remains one of the most popular material choices for balustrades and handrails.

Criteria Level: 2.01

In warmer northern climates timber used in balustrade and handrail construction should be either Above Ground Durability Class 1 species with any sapwood present treated to H3 (or higher) or, H3 (or higher) treated softwood such as slash, hoop or radiata pine. Preservative treatment needs to comply with AS1604.

In the cooler, more temperate southern climates it should be either Above Ground Durability Class 2 species or better (with any sapwood present treated to H3 or higher) or, H3 (or higher) treated softwood such as slash, hoop or radiata pine. Again, preservative treatment needs to comply with AS1604.

Lower durability species can also be utilised however with these careful detailing of joints with maintenance of protective coatings and/or installation of protective shielding on top of exposed timber edges will be necessary.

Care should be taken to ensure that water is not trapped by end grain abutting horizontal surfaces.

Criteria Level: 2.02

The timber should be free of any major strength reducing features, be straight grained and in accordance with the following:

Hardwood (including meranti): AS 2796 Timber - Hardwood - Sawn and milled products - clear or select grade;

Softwood (including imported softwood): AS1786 - Joinery timber milled from Australian grown conifers - clear grade

In addition, finger jointed timber shall comply with AS5068 Timber - Finger joints in structural products and laminated timber shall comply with AS1328 Glued laminated structural timber.

Criteria Level: 1

For timber used in external applications, a key objective in applying and maintaining finishes, paints and stains is to maximise the service life of the timber by minimising the effects of weathering. Exposure to sun and rain leads to wetting and drying and subsequent splitting and distortion. For external balustrades, choice of timber must be appropriate for long term exterior exposure and the application and maintenance of finishes should not be considered a substitute for the inherent durability (natural or by treatment) of the underlying timber.

Criteria Level: 1.01

Nail holes should be stopped with an exterior grade wood filler and dirt or any loose material removed prior to coating. All surfaces, ends and joints should be primed prior to assembly with a quality solvent based alkyd primer or stain. On completion of installation, final top coats of an exterior paint or stain should be applied, with all steps in accordance with manufacturer's recommendations.

Criteria Level: 1.02

Pink pre-coated handrail and balustrade components should be sanded back and dusted off to remove any coatings prior to finishing. Nail holes should be stopped with an exterior grade wood filler and all surfaces, ends and joints primed prior to assembly with a quality, solvent based alkyd primer. When the primer has dried, apply two full coats of premium 100% acrylic exterior topcoat. Dark coloured paints and stains should be avoided as they heat timber to elevated temperatures that increases loss of moisture and subsequent shrinkage and checking. Decay is also more active at higher temperatures. All finishes should be applied and used in accordance with the manufacturers recommendations.

Criteria Level: 2

Frequent wetting of the rail and balustrade should be avoided and cleaning should involve sweeping down rather than hosing down.

Reapplication of finishes will be required at regular intervals, depending on finish type and degree of exposure. Before recoating the rail and balustrade should be thoroughly cleaned and debris removed from around steps. Recoating should be carried out in accordance with the manufacturer's recommendations.

Criteria Level: 1

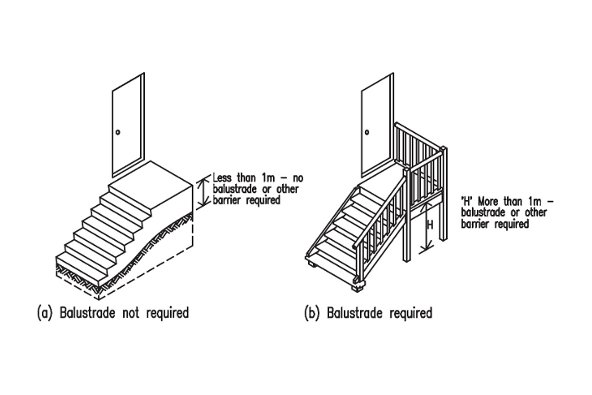

Handrails and balustrades for all buildings are required to comply with the Building Code of Australia (BCA). The BCA stipulates that a continuous balustrade or handrail must be provided along:

- The side of any roof to which public access is provided.

- Any stairway, ramp, floor, corridor, hallway, balcony, verandah, mezzanine, access bridge or the like.

- Along the side of any path of access to a building, if it is not bounded by a wall and more than one metre above the surface beneath.

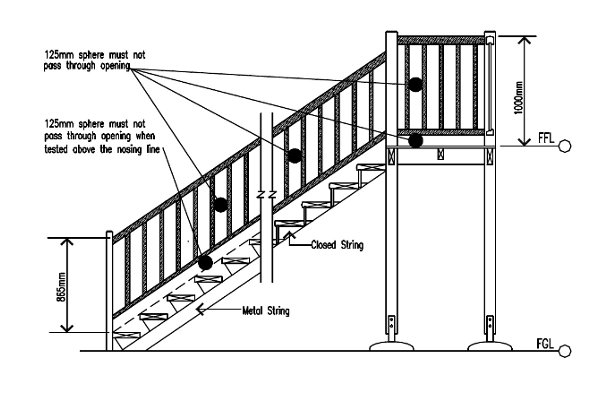

The height of a balustrade or other barrier must not be less than one metre above the floor of any access path, balcony, landing or the like and not be less than 865 mm above the nosings of the stair treads or the floor of a ramp.

Openings in balustrades (including decorative balustrades) or other barriers must be constructed so that they do not allow a 125 mm sphere to pass through. Floors more than four metres above the surface beneath, any horizontal elements within the balustrade or other barrier between 150mm and 760mm above the floor must not facilitate climbing.

Criteria Level: 2

Several structural properties must be considered in the design and construction of handrails and balusters.

Criteria Level: 2.01

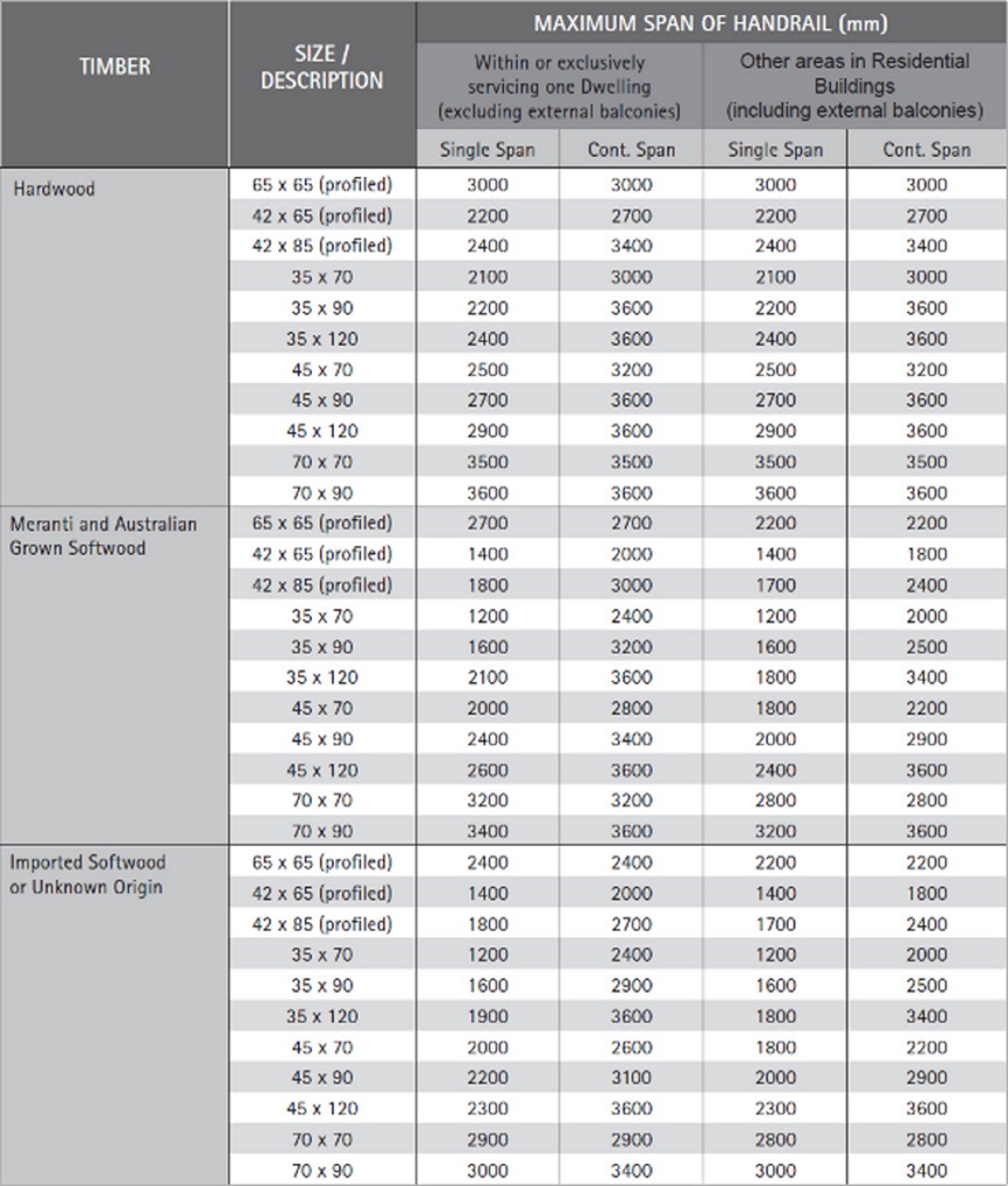

Handrail sizes and spans should be in accordance with the following table:

Criteria Level: 2.02

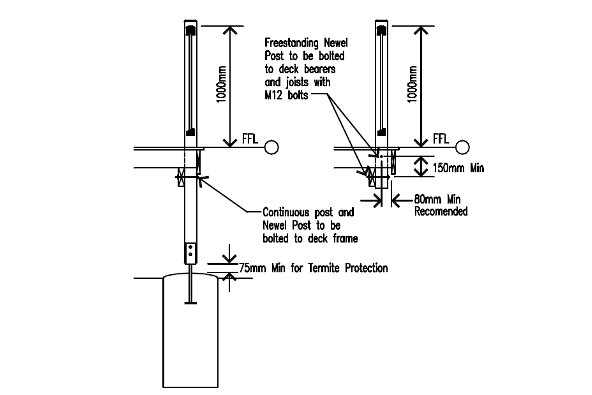

Posts and newel posts shall have a minimum stress grade of F5. Where they only support handrails, the minimum size of posts and newel posts should be 80 x 80 mm (maximum post spacing 3600 mm and height of 2700 mm). Refer to AS1684 to determine the size for posts that support additional loads such as roof or flooring.

Criteria Level: 2.03

The minimum size of infill/balusters should be:

Hardwood: 19 x 19 mm or 21 mm diameter

Softwood: 19 x 42 mm, 32 x 32 mm or 25 mm diameter

Criteria Level: 2.04

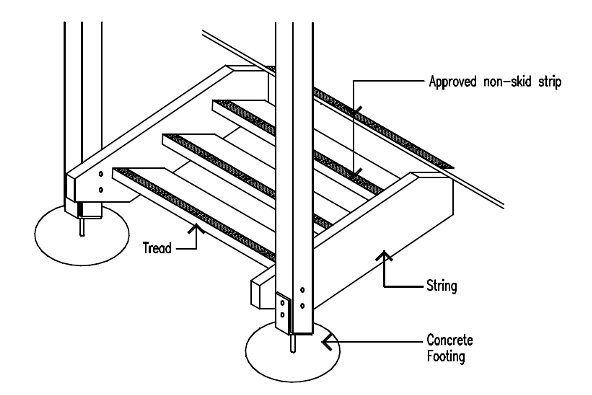

Connections are essential in the transference of loads from handrails to posts. All metal connections used in external balustrade and handrail construction should be of a non-corrosive material.

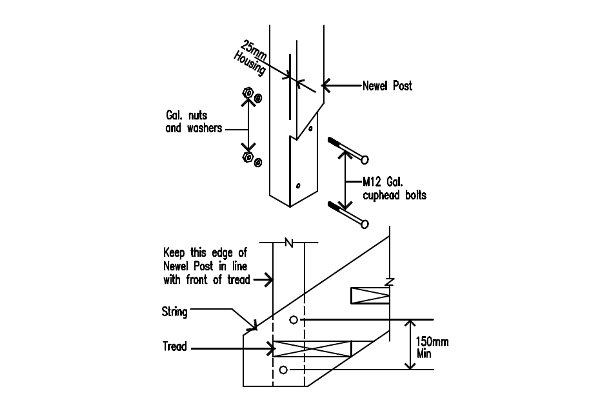

Posts and newel posts should be connected to floor framing/stringers in accordance with the following figures.

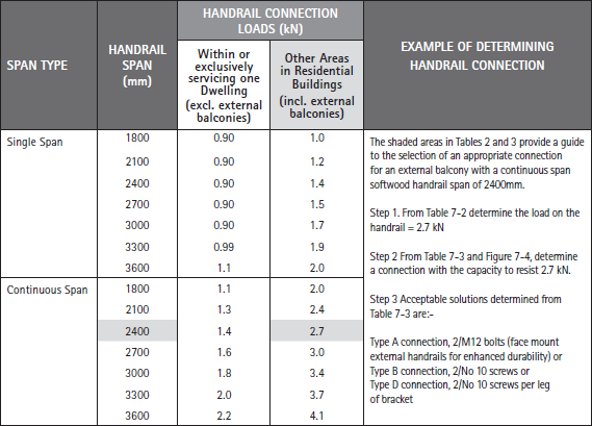

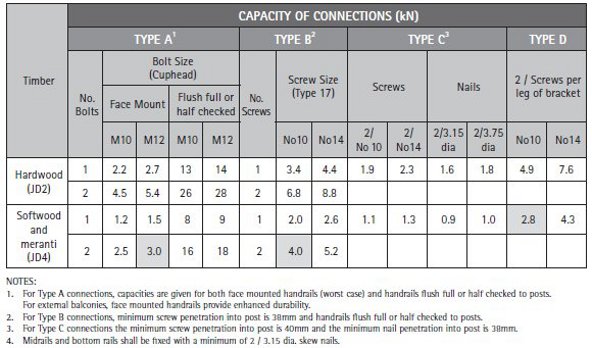

Acceptable loads on handrails and the capacity of handrail connections are outlined in the tables: