Spotted gum is a premium Australian hardwood that is used widely in structural, exterior and internal applications.

Lemon-scented Gum, Spotted Irongum, Eucalyptus maculata, Corymbia citriodora, Eucalyptus citriodora, Corymbia henryi, Eucalyptus henryi

Corymbia maculata, Corymbia citriodora and Corymbia henrii

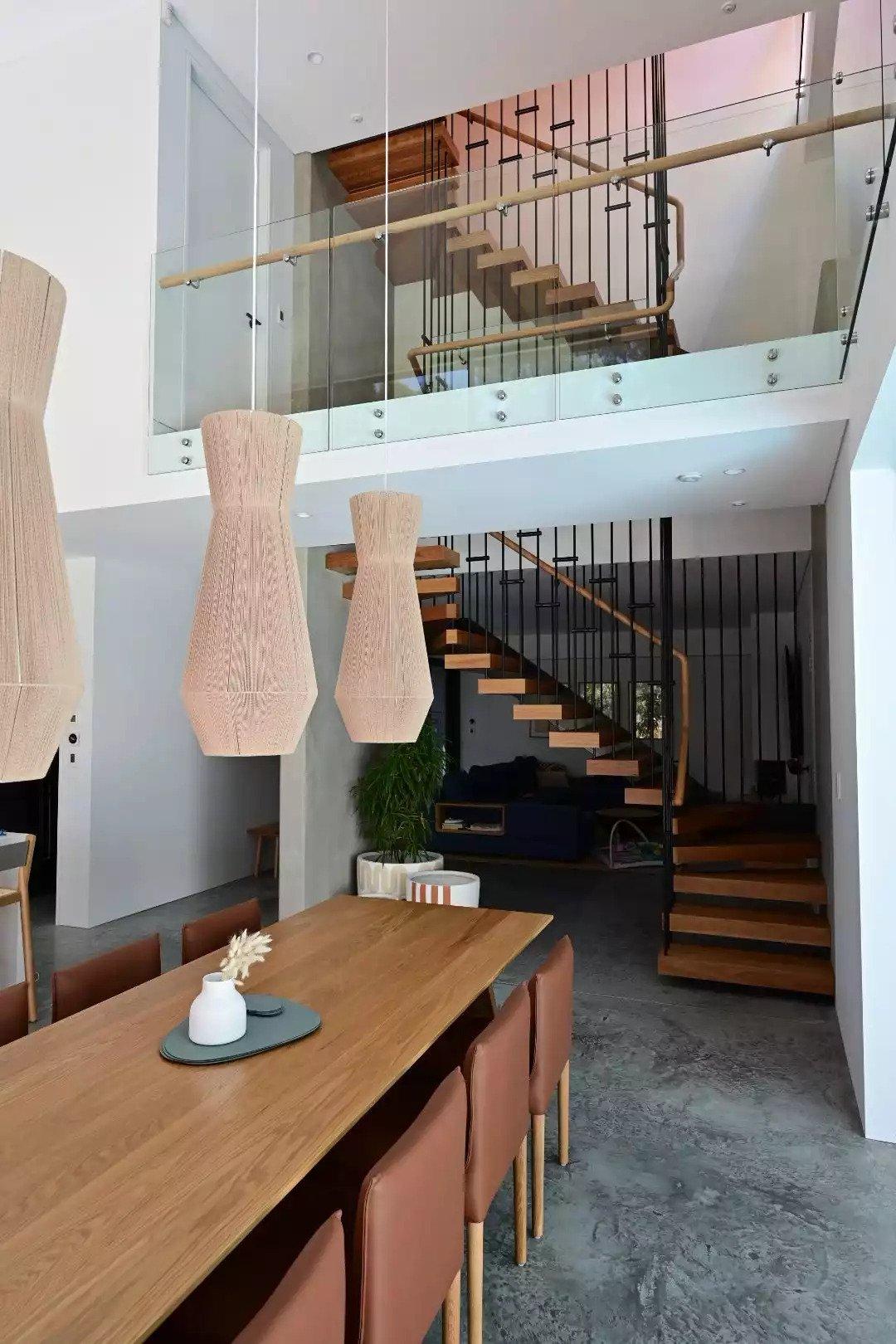

Spotted gum is one of Australia’s premium native hardwoods with a striking appearance and a high degree of natural durability and strength, making it an ideal timber for a variety of structural, exterior and interior applications. Architects and designers throughout the world value spotted gum timbers for their back-sawn grain structure, attractive markings and vibrant colour palette.

Spotted gum is the common name for four species that grow along the east coast of Australia, from northeast Victoria to the northern tablelands of Queensland, with some occurrence in western areas of southern Queensland. Sawn timber from these species is generally available throughout Australia. These species have straight, slender trunks with smooth bark that is shed in patches, giving the trees their characteristic spotted appearance.

The species referred to as spotted gum vary in appearance but not in durability class or other properties. The heartwood ranges from light brown through to dark red-brown hues. Sapwood is usually white to light brown in colour. The presence of a wavy grain can produce an attractive fiddle-back figure. The wood has a slightly greasy feel, a characteristic that aids machining and boring. Spotted Gum components that are 18mm thick or greater do not require fire retardant treatment for use in construction in bush-fire prone areas.

Spotted gum is used in engineering applications such as wharf and bridge construction, railway sleepers, cross-arms and mining timbers. It is suitable for a range of building applications, such as posts and poles, framing, flooring, lining, decking and cladding. Spotted gum is also used in the manufacture of veneer and plywood. Other applications include boatbuilding, tool and implement handles, polo sticks and diving boards. Compared to other Australian hardwoods, spotted gum is a minimal staining timber as it is less prone to bleed-through of tannins than other species. Spotted gum is also a good timber for carving and woodturning.

Shrinkage

| Very Low | Low | Medium | High | Very High | |

|---|---|---|---|---|---|

|

|

|

||||

|

Tangential :

|

6.10% | ||||

|

Radial :

|

4.30% | ||||

|

Unit Movement Tangential:

|

0.38% | ||||

|

Unit Movement Radial:

|

0.32% |

Strength Group

| Very High | High | Reasonably High | Medium High | Medium | Reasonably Low | Low | Very Low | |

|---|---|---|---|---|---|---|---|---|

| Unseasoned: | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 |

|

|

||||||||

| Seasoned: | SD1 | SD2 | SD3 | SD4 | SD5 | SD6 | SD7 | SD8 |

|

|

Stress Grade

|

Structural No. 1 |

Structural No. 2 |

Structural No. 3 |

Structural No. 4 |

Structural No. 5 |

|

|---|---|---|---|---|---|

| Unseasoned: | F27 | F17 | F14 | F11 | F8 |

| Seasoned: | F34 | F27 | F22 | F17 | F14 |

Density per Standard

| Seasoned: | 990kg/m3 |

|---|---|

| Unseasoned: | 1180kg/m3 |

Joint Group

| Very High | High | Reasonably High | Medium | Low | Very Low | |

|---|---|---|---|---|---|---|

| Unseasoned: | J1 | J2 | J3 | J4 | J5 | J6 |

|

|

||||||

| Seasoned: | JD1 | JD2 | JD3 | JD4 | JD5 | JD6 |

|

|

Colour

| White, yellow, pale straw to light brown | Pink to pink brown | Light to dark red | Brown, chocolate, mottled or streaky | |

|---|---|---|---|---|

|

|

||||

Mechanical Properties

|

Modulus of Rupture - Unseasoned:

|

98 |

|---|---|

|

Modulus of Rupture - Seasoned:

|

142 |

|

Modulus of Elasticity - Unseasoned:

|

16 |

|

Modulus of Elasticity - Seasoned:

|

19 |

|

Maximum Crushing Strength - Unseasoned:

|

53 |

|

Maximum Crushing Strength - Seasoned:

|

76 |

|

Impact - Unseasoned:

|

23 |

|

Impact - Seasoned:

|

24 |

|

Toughness - Unseasoned:

|

High - 25 Nm and above |

|

Toughness - Seasoned:

|

High - 25 Nm and above |

|

Hardness - Unseasoned:

|

8.8 |

|

Hardness - Seasoned:

|

10.1 |

Durability

| Low | Moderate | Reasonably High | High | |

|---|---|---|---|---|

| (0 - 5 yrs) | (5 - 15 yrs) | (15 - 25 yrs) | (more than 25 yrs) | |

|

In-Ground:

|

|

|||

| (0 - 7 yrs) | (7 - 15 yrs) | (15 - 40 yrs) | (More than 40 yrs) | |

|

Above ground:

|

|

|||

| (0 - 20 yrs, usually < 5) | (21 - 40 yrs) | (41 - 64 yrs) | (More than 60 yrs) | |

|

Marine Borer Resistance:

|

|

|

Lyctid Borer Susceptibility:

|

Susceptible |

|---|---|

| Lyctid Borer Susceptibility - Other: | |

|

Termite Resistance:

|

Resistant |

Fire Properties

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

|

EFH Ignitibility: |

|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|

EFH Spread-of-Flame Index:

|

|

||||||||||

|

EFH Smoke-Developed Index:

|

|

|

Critical Radiance Flux - Lower:

|

>2.2 and <4.5 |

|---|---|

|

Critical Radiance Flux - Higher:

|

≥4.5 |

|

Smoke Development Rate:

|

<750 |

| 1 - non-combustible | 2 - reasonably non-combustible | 3 - slightly combustible | 4 - combustible | |

|

Fire Properties Group Number: |

|

| Group Number - Other: | For plywood: Fire Properties, EFH Spread-of-flame Index: 7 |

|---|---|

|

Average Specific Extinction Area:

|

<250 |

|

Bushfire Resistance:

|

BAL 12.5, 19 and 29 – All AS3959 required applications |

Spotted gum timbers are available in a range of colours depending on the location of the source forest. The heartwood ranges from light brown through definite browns to deep red-brown hues. Sapwood is white to light brown in colour and can be up to 50mm wide. Spotted gum is a moderately coarse and uneven textured wood with some timbers having the additional feature of a wavy grain, giving rise to an attractive fiddleback figure.

Spotted gum has a long history of use in engineering applications such as wharf and bridge construction, railway sleepers, cross-arms and mining timbers. It is used for a variety of applications, including structural building members, such as posts and poles, and for framing, flooring, lining, decking and cladding. It is also used in boatbuilding and is the primary Australian timber used for the handles of tools and implements that are subject to high impact forces. Spotted gum is a suitable carving and woodturning timber and is used in the manufacture of both indoor and outdoor furniture. Outdoor furniture in spotted gum has consistently won industry awards in Australia and is exported to destinations around the world.

NSW