Australian Softwood Environmental Product Declaration

Blog by: Stephen Mitchell, Principal of Stephen Mitchell Associates and former Sustainability Manager with the Timber Development Association

In this, the first of a series of blog posts, Stephen talks about the recently released WoodSolutions Environmental Product Declaration – Softwood Timber

Now it’s easier for designers and material specifiers to confidently design more sustainable structures and gain recognition under the Green Building Council of Australia’s Green Star building rating scheme.

What does the release of the first Environmental Product Declaration (EPD) for Australian sawn softwood mean for specifiers and consumers of timber?

Well for the first time we have some credible numbers explaining key environmental impacts of the sawn softwood that is grown and manufactured in Australia. These numbers are reported across six different environmental indicators and can be used to quantify, and even get recognition for, timber’s contribution to significantly reducing the environmental impacts of buildings.

The figures in the EPD are based on data collected by the CSIRO from sawmills and wood product manufacturing facilities across Australia.

What does this EPD show?

One of the EPD’s key environmental indicators is Global Warming Potential. That is, the contribution of greenhouse gases such as carbon dioxide and methane to climate change.

This EPD shows that for every cubic metre of Australian sawn softwood produced, 900 kilograms of carbon dioxide has been absorbed to make the wood (about 12% by weight of sawn softwood is water).

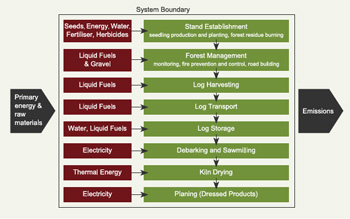

There are some carbon dioxide emissions from production processes such as forestry management, log harvest, haulage, sawing, kiln drying and planing. These emissions are mainly the result of burning of fossil fuels such as diesel oil and coal to generate electricity. For each cubic metre of sawn softwood these emissions total about 270 kilograms of carbon dioxide.

So, on balance, upon leaving a sawmill a cubic metre of sawn softwood timber has an embodied carbon footprint of negative 630kg. This is what’s known as a negative carbon footprint which is “better than carbon neutral”. Timber from sustainably managed sources, such as Australian softwood, is significantly ahead of most other building products in this regard.

The EPD shows that the vast majority of Australian softwood is sourced from plantations certified to internationally benchmarked sustainable forest management standards – justifying the “better than carbon neutral” footprint.

To put this into a building context, an EPD for cross-laminated timber (CLT) - a softwood product that requires a greater amount of processing than plain sawn timber as well as transport into Australia – was used to undertake a life cycle assessment study of the 10 storey Forte timber apartment building in Melbourne. The study, done by RMIT University, found a 1,400 tonnes lower carbon footprint compared to a standard reference building. This is a massive 20% reduction across the whole life of the building.

Now with this Australian EPD designers will be able to assess on a building-by-building basis the carbon benefits of using Australian timber - especially the lower carbon footprint.

Gaining Recognition under Green Star

This EPD can also be used by designers and purchasers of Australian sawn softwood products such as structural pine, mouldings, linings and panelling to gain recognition under the Green Building Council of Australia’s Green Star building rating scheme.

This EPD, as are the other EPDs about to be published, complies with the requirements for an “industry-wide EPD” under the Green Star system. It may be used by project teams specifying Australian sawn softwood from the manufacturers listed in the EPD to obtain points under the Materials category of the current Design & As Built and Interiors Green Star rating tools, as well as under the Innovation Challenge category of the legacy rating tools.

In following blog posts I will discuss the key findings in the EPDs for Australian hardwood, particleboard, MDF and plywood products as well as aspects of end-of-life considerations that are important considerations for materials such as timber.