Tamarama NSW

Australia

Overview

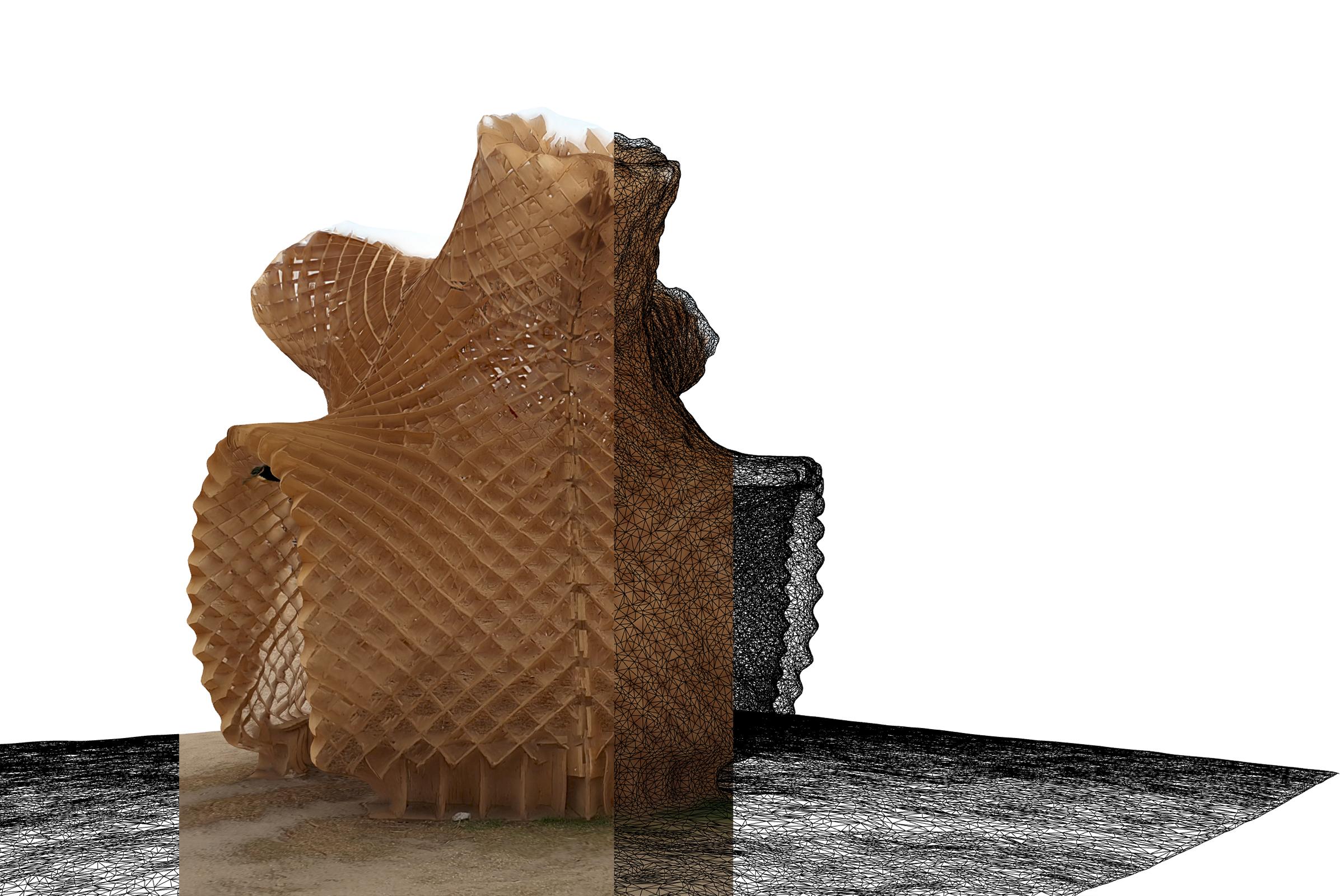

SuperSuccah is a lightweight plywood pavilion fabricated with a CNC machine and built to traditional Sukkot festival rules and specifications.

The structure is a contemporary re-imagining of the Succah, an ephemeral Jewish shelter built once a year during the festival Succot.

SuperSuccah is a collaboration between the designers Supermanouevre, TTW Engineers and the University of Technology Sydney (UTS). The structure was commissioned by Shalom, a Jewish organisation in Sydney, for ‘Succah by the Sea’, as part of the ’Sculpture by the Sea’ festival in Sydney, in 2019. With a material budget of only $14,000, much of the project was executed as a passion project by the collaborators.

SuperSuccah offers an ephemeral environmental experience through its complexly formed, intricately layered structure, consisting of hundreds of curved and twisting plywood strips .The structural skin forms all aspects of the project, with no additional walls, roof, permanent footings, or cladding to distract from the structural beauty.

The permeable skin serves to amplify visitors’ awareness of subtle changes in the weather, the environment, and the night sky. Through coupling computational design and analysis techniques with digital fabrication processes, the project forms part of a larger architectural investigation by the designers. Supermanouevre aims to produce unique, culturally valuable and high performing architecture achieved through the expressive and efficient use of geometry and material.

Sukkot festival is about Jewish families and communities self-building their own temporary gathering spaces with minimal means, as an acknowledgement of the impermanence of material wealth. Often made and remade on the same site, Succah are simultaneously objects and rituals. Many of the structures benefit from annual refinements to their structural strength and habitability.

Supermanoeuvre have designed an extremely lightweight shelter that has been finely calibrated, through digital simulation, to negotiate the precise climatic conditions of its unique place on the plateau between Bondi and Tamarama.

The structures thin strips of veneer are oriented to alternately allow or prevent sun, wind and rain penetration. Three ‘sky portals’ frame slowly rotating views of specific constellations at night.

Project team

Structure

The structure pushes the boundaries of what is possible in thin-plate timber design. The architects worked closely with the collaborating engineers, TTW, to capitalise on the inherent properties of timber. The gridshell structure offers an incredibly lightweight structural approach to resisting the immense wind loads of the highly exposed coastal location.

The structure uses a surfacing method recently developed in Germany called the ‘asymptotic strip’ method, which allows doubly-curved structures to be constructed using only rectangular strips, with simple perpendicular joints, that bend and twist in order to follow the surface.

This resulted in a 30-40% reductional in material use than a typical curved element. To create this kind of form with this kind of method, timber was not only an ideal choice, but the only viable option.

To achieve the high levels of twisting and bending required, the plywood strips were saturated for 5-15 minutes before assembly. Once assembled, the timber dries and attempts to straighten, which prevents the notched joints from moving. This allowed the designers to eliminate almost all mechanical fixings (and the embodied energy that goes with them.)

As the project was a temporary one, the structure was designed for disassembly and reassembly. SuperSuccah has since been relocated to the University of Technology in Sydney as a temporary installation, before moving to a permanent home later on.

All plywood used in the project was sustainably sourced and from certified Australian timber manufacturers. The designers note that ’an additional benefit of working with certified Australian plywood was the visual and performance consistency, ready availability of multiple thicknesses of plywood of matching species.’