Overview

This multiple winner from the 2010 Australian Timber Design Awards just keeps on getting better as the spa complex is developed.

Architect Pouné Parsanejad says although the design is first-and-foremost Australian, Gwinganna also achieves a level of luxury and warmth evident in the best Asian spas.

“It is a ‘place’, not just a building – a celebration of nature, life and of the human body … place of ritual and sensory delight; of reflection and meditation. Or perhaps it is simply a journey.”

The ‘journey’ embraces three individual wings that come together to form the entire spa compound over seven levels, cascading and contoured to the site. The buildings are such that guests are submerged and cradled within the landscape and the natural surroundings. It is also fully self-sufficient in terms of water and effluent processing.

Gwinganna features timber in many forms and across several species.

Story and pictures by special arrangement with timber+DESIGN International magazine.

Structure

The main entry building is a combination of concrete and timber. Australian hardwood features as an exposed ‘colossal’ structural truss system, made from salvaged and re-milled bridge girders from Western Queensland. They successfully accommodate the double-volume heights and the aesthetic grandeur of the design concept. The trusses are linked in two back-to-back, fan-like formations.

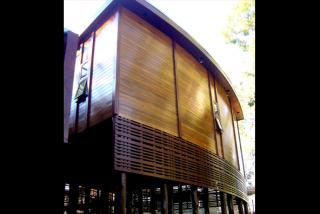

In contrast, framing of the wing buildings is predominantly timber, but employed much like the ideology of the classic elevated Queenslander – acting as a skeletal system behind the exposed skin of the cladding. What is unique about these buildings is the sub-floor framing where close to 100 recycled telegraph poles of varying diameters hold the buildings.

Structural trusses, columns and hand railing are re-used bridge girders. This is also the case for the ironbark posts holding the external cladding. The spotted gum/ironbark mix used for the internal flooring is also recycled. Door and window joinery is recycled karri from demolished wool stores, and sustainably harvested spotted gum is used for cladding, ceilings and decking.

Exterior

Exterior curved cladding is spotted gum, with 19-mm-thick t&g wire-brushed boards slotted into rebated 140 mm reclaimed ironbark posts. The exterior is coated with a satin finish. Spotted gum lining the entry walls creates a flow from the timber floor to the soaring open timber trussed and lined ceilings.

The upper level of the entry building is referred to as the ‘Whisper Lounge’ – it's design stemming from the ideology of a fallen leaf under the gum trees that form the centre of the spa sanctuary. Mixed 180 mm recycled ironbark and spotted gum boards (coated with water-based polyurethane) were laid to emulate the fine detail of a gum leaf.

“Selecting timber as the predominant building material enforces the commitment to ESD principles,” says the architect. “We not only acknowledge the longevity and life spam of Australian hardwoods, but by selecting so much reclaimed timber we have reduced the total environmental impact of production.”

Interior

Recycled timber detail throughout adds richness, beauty, warmth and power to the project and exemplifies innovative sustainable design. But finding enough of the right wood was a challenge overcome by getting an early understanding of what the supplier had to offer.

The main element of the roof structure is a series of large-span timber trusses made of heavy, recycled timber – left exposed in a fan-like pattern to form part of the architectural feature. They are of Vierendeel form, strengthened by a pair of cross braces made of galvanised bars, with a turn buckle arrangement to cater for the large shear force near supports, and to control deflection.

Connections are detailed with vertical elements butting against the top and bottom chords. Coach screws are driven through the top and bottom chords into the verticals, with braces threaded through the top and bottom chord. The approach reduced cutting and notching, labour and overall cost.